Coding and Marking on Plastic

We offer expert product identification solutions for plastic marking including inks for enhanced adhesion, specifically designed to adhere to printing on a wide variety of plastics such as PVC, nylon, OPP, PP and PE.

Polyethylene (PE) is the most common plastic used for rigid packaging. Application of production codes and date codes during the production process can be easily done with a Linx marking and coding solution.

Our coders are designed to be easily integrated into your production environment, built with IP65-rated printers to keep dust and airborne contaminates from the printer. Traceability information, barcodes, variable data, and multi-line codes can be clearly marked on plastic containers with our robust and reliable printers.

Inks for Coding and Marking on Plastic

Our pigmented inks are ideal for high-contrast coding and marking of light or dark materials such as plastic cables or extrusions. There is also a range of inks adhering to plastic film, grease and oil and dry surfaces. Pigmented inks retain their clarity for years, even if the printed plastic products are stored outside.

Plastic Application

Linx has printers perfect for marking and coding on plastics, thermoplastics, polyethene, polypropylene, polycarbonate and many other plastics used in several industries and applications.

Shrink Wrap and Plastic Film

This material allows the customer to see the product and keep it protected from air. It is one of the most popular packaging materials, but printing on a non-absorbent surface can present some challenges.

- CIJ can mark expiry dates, and traceability data on non-absorbent surfaces with ease without specialised ink

- Lasers can mark on static capable of avoiding pin holes with special fonts

PET Bottles

PET bottles are popular as they are transparent, robust, and light. Although this material is widely used in the beverage industry it is also used in other industries such as personal care. Marking such as best before codes, batch numbers, EAN codes, matrix codes, barcodes and even logos.

- CIJ’s are capable of coding clearly in wet, dry, and dusty environments. Specialised inks available that can be removed for customers looking to reuse their bottles

- Lasers can code directly on a product without any damage coding up to 9,000 bottles an hour

Flow Wrap

This material is most used in the food industry as it is lightweight and used to package a variety of products, minimising transportation costs. Printing on such low-density polyethylene is not an easy task

- CIJ are capable of non-contact printing onto a variety of surfaces, that being uneven, non-absorbent or flow wrap. With our specialised inks, we have excellent print adhesion tackling water, grease, and oil.

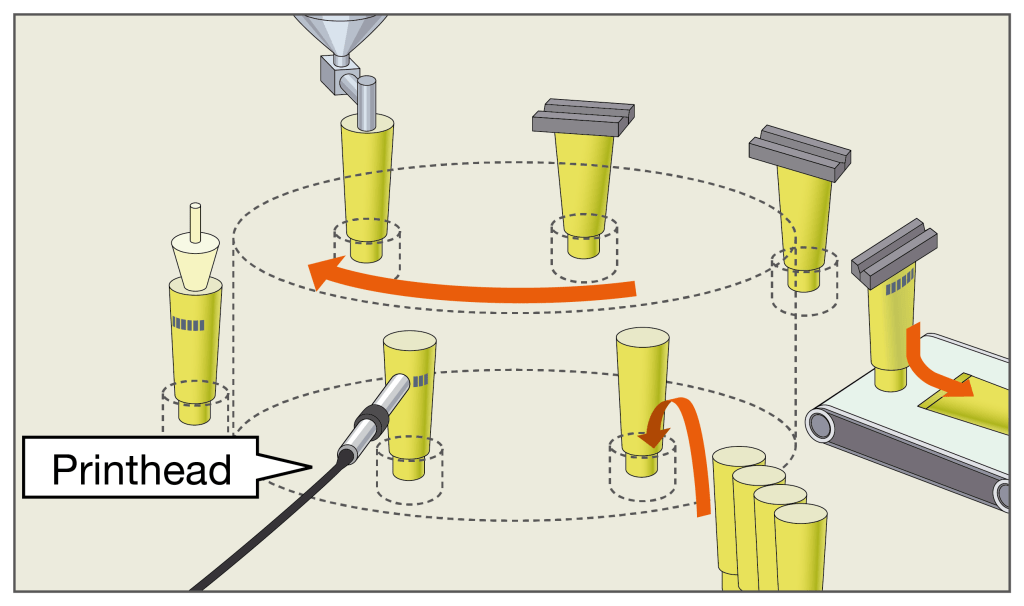

Printing on plastic tubes

The continuous inkjet printer can be incorporated into the rotary plastic filling machine easily. Not only can this machine print on plastic tube, but other substrates such as cardboard cartons and exterior cases, having a machine play two roles on your line.

Printer Types for Plastic Printing

Continuous Inkjet

Non-contact, high-speed coding with clean, reliable operation in challenging environments.

- Inks able to stick on greasy, oily, and dry surfaces

- A robust touchscreen can be operated even when wearing gloves

- Range of coating formats that allow coding 20mm in height

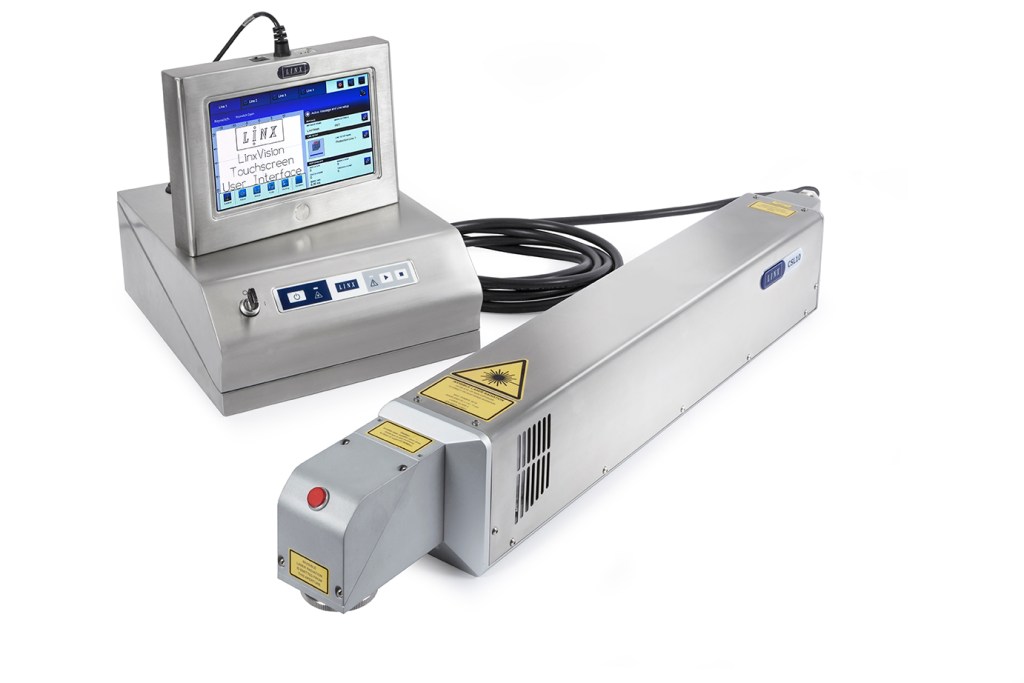

Laser Coder

Fast, non-contact solution for permanent food packaging applications. The Linx CSL60 is a High powered laser coder for hard-to-mark plastics.

- Thermal change – melts the surface – PP etc, for visible marks

- Permanent coding for ultimate traceability

- Capable of marking static on high speeds

- No consumables needed

Request a Print Sample

See what your code will look like on plastic.

To find out more information and to request your samples with no obligation, click the button below.

Working with Linx

Linx Printing Technologies have been in the industrial coding and marking industry for 35 years. We have built a team of high specialists to support all our customers through their buying process and aftercare. We have a set of highly qualified and experienced sales managers to assist from the very beginning, offering sample marking, free site visits and advice across all industries.

Worried you won’t have support after the sale? We have a UK service maintenance and support team to maintain the quality of the machines to run efficiently and effectively on your production line. To offer ultimate support we have a team of highly qualified technical support team available should you have an issue with any of our machines, we are on hand to help you get coding quickly again.

Related Industries

Confectionery

Meeting the demand for different types of plastic packs, in addition to the traditional paper or card outer wrappers.

Food Industry

Printers for paper labels, cardboard and plastic food packaging, bottles, and even directly onto food products themselves such as eggs or cheese.