Coding, Cars and Counterfeiting

“No one will own a car in 20 years,” Bob Lutz, one of the biggest names in the car industry, recently predicted, in reference to the growing trend of ride-sharing. Add to this the ongoing emergence of the electric car, the self-driving car, and the connected car – and it’s clear that the future of the automotive industry will look very different to the present.

But even as the car world evolves in new and exciting ways, one thing that has remained consistent is the problem of counterfeiting.

Fake car parts – including brake pads, tyres, suspension components, steering linkages and other accessories – are being distributed around the world in ever-greater quantities. Indeed, it is estimated that the total economic and social costs due to counterfeiting and piracy worldwide will rise to $1.54-1.87trn by 2022.

How coding can help

The good news is that, just as cars have continued to develop and become more sophisticated, the coding and marking industry has also evolved over the years, meaning that there are numerous solutions now available to help combat the counterfeiters.

The latest Continuous Ink Jet (CIJ) printers, for example, are able to produce hard-wearing and durable codes of different sizes onto almost any substrate. These can be as visible or discreet as required, helping to reassure users of the authenticity of a component.

As part of this, recent CIJ ink developments have seen the introduction of inks that provide high contrast prints on a wide range of substrates, including dark surfaces, PVC, rubber, glass, and electronic components. Many of these inks can also offer resistance to acids, alkalis, and high levels of light and heat.

In addition, Data Matrix codes and scannable barcodes now enable manufacturers to print traceability codes in a secure format onto their products. Likewise, quality coding solutions can print company logos onto components to reassure consumers that the product is genuine.

A permanent reminder

Another coding technology to help frustrate the counterfeiters is laser, which leaves a permanent mark that will withstand every effort to rub it off. This technology has also evolved over the years, leading to a significant reduction in the purchase price of laser coders. A new generation of compact models has also been introduced, offering an affordable alternative while still maximising functionality.

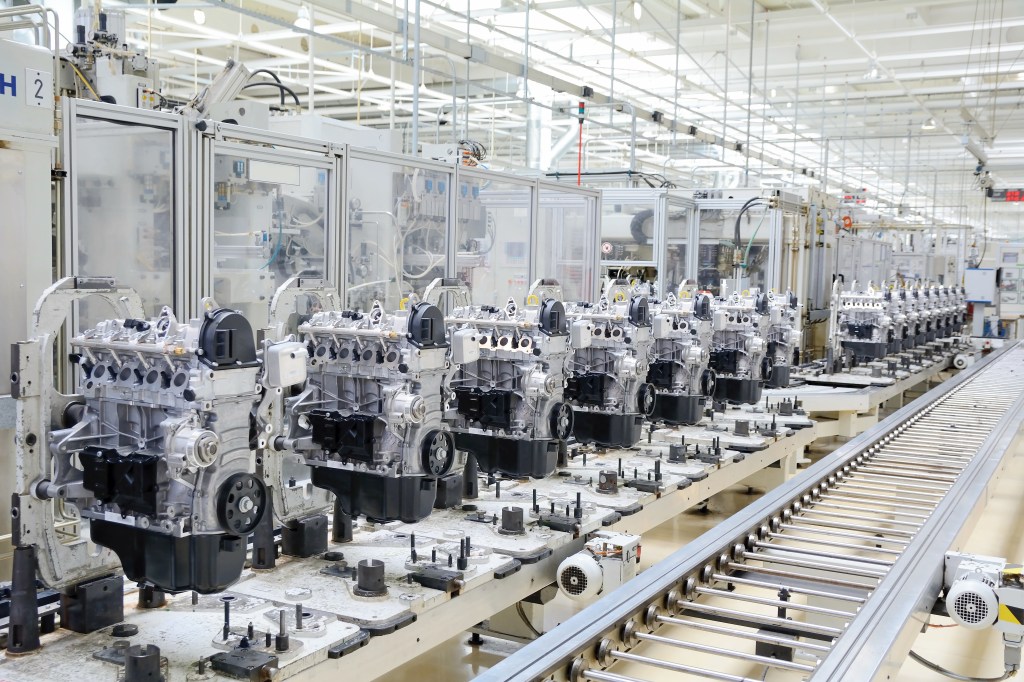

Fibre laser technology is now more widely available than before, and has the benefit of applying permanent traceability codes onto bare metal, on both stationary and moving production lines. It is being used increasingly in both the automotive and aerospace industry where robust regulations exist around traceability of parts.

Quality and Uptime

The other vital roles coding plays on the production line should not be forgotten either. A quality code will not only meet relevant compliance and help prevent counterfeiting, but will also do much to reflect the overall quality and reputation of a product or brand.

Easy-to-use and set-up printers, with features such as simple message creation and transfer, will help to ensure a right-first-time approach that avoids costly mistakes and reworking.

Contract manufacturers in particular will benefit from a printer with a large message store and an easy to use interface. This makes selection from a range of customer logos is quick and error-free, and downtime is reduced between product changes.

Reliable printers that are capable of operating continuously in a particular factory environment (for example, having the relevant IP protection for dusty or humid conditions or with a sealed printhead to avoid liquid or particle contamination) will avoid unplanned stoppages that affect production. So too will printers that provide early notification of low fluid levels and have long service intervals.

Consistency in a changing world

We may be entering a brave new world of ownerless, driverless cars, but printing and coding technology is at least going in the right direction to give component suppliers the ability to meet compliance, demonstrate quality and maintain production targets – while helping to keep the counterfeiters at bay.