Introducing Our New Returnable Bottle Ink

In the current packaging and the environment debate, plastic is one of the biggest talking points. Raised public awareness about plastic waste has led to sales drops in plastic-packaged goods , while our own consumer research recently found that 89% of Brits are concerned about the impact that soft drink packaging has on the environment .

No wonder, then, that ‘single-use’ was recently named word of the year by Collins Dictionary .

All this naturally has an impact on drinks packaging, and sure enough many brands are now looking to non-plastic alternatives. In recent times we have seen Lucozade trial edible pods for its energy drinks and A2 Milk switch from plastic to paper-based cartons , to name two. Another material on the rise again is glass – attractive not just for its recyclability but also its potential to be reused.

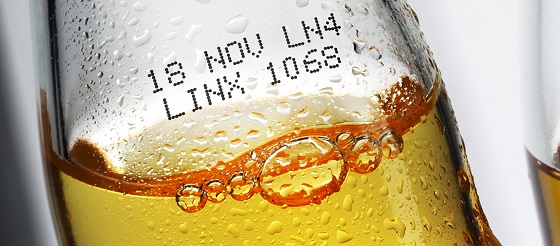

In order for this to happen, however, batch and date codes must be removed before being replaced with new ones – a procedure that requires a special type of removable coding ink. That’s why, when 91% of the consumers we spoke to said they would welcome a scheme to enable the widespread reuse of glass bottles , we decided to create our Linx Black bottling ink 1068.

Beverage products coded using Linx Black bottling ink 1068 can be returned before having their codes removed during the bottle-washing process, so that they can be refilled and printed onto again. This can happen numerous times before the glass bottle is finally retired and recycled.

The environmental benefits of such a scheme are significant. For every glass bottle that gets reused, one less has to be manufactured. If a glass bottle can be used 16 times rather than once, then only 6.25% of the glass bottles currently produced need to exist – a reduction of 937,500 from every million bottles manufactured.

The return to more glass beverage packaging not only has the potential to avoid plastic waste but also significantly reduces energy expenditure, far outstripping the benefits even of recycling. And everyone is a winner: the public’s wish for reductions in waste is resoundingly answered, and businesses maximise their profits by greatly reducing their materials expenditure and resources.

Nor is there any compromise on quality. Linx Black bottling ink 1068 has been designed to cope with the particular challenges of coding for bottled drinks, delivering high-quality, durable codes so that customers can meet relevant regulations and protect their brands.

This includes the ability to print clearly onto glass in cold-fill bottling and in humid environments – common requirements for coding in the drinks sector. Indeed, almost every conceivable challenge – pasteurisation, immersion in ice water, storage for long periods in warehouses, refrigeration – is comfortably withstood by the Linx Black bottling ink 1068.

This means the ink is suitable for any drinks company’s coding needs – whether actively seeking to code onto returnable glass bottles or simply interested in the option to do so at some point should the technology become widespread.

For more information on how to find the best solution for coding in the beverage sector, read our white paper

___________________________________________________________________________________

https://www.conveniencestore.co.uk/news/small-retailers-report-sales-drop-in-plastic-packaged-products/571903.article

Linx Toluna survey

https://www.independent.co.uk/life-style/single-use-word-of-year-2018-collins-dictionary-plastic-pollution-environment-a8621406.html

https://www.thegrocer.co.uk/home/topics/environment/lucozade-sport-to-trial-drinks-and-gels-in-edible-pod/571027.article

https://www.packagingnews.co.uk/news/markets/drinks/a2-milk-switch-plastic-carton-26-09-2018

Linx Toluna research