The Importance of Ink Selection in Industrial printing: How to Choose the Right Ink for your Printing Needs

For industrial printing, selecting the perfect ink can be challenging. From compatible substrates to colour slippage, there are many factors that need to be considered when it comes to choosing the right ink for a specific project or application. Here you will find a comprehensive and easy-to-follow guide on how to select the appropriate type of ink for your print job – allowing you to gain an improved finish with optimum outputs. Whether it’s latex flexographic inks or UV curable solvent inks, our goal is to provide knowledge and insight into which type of printing will best suit your individual needs.

What is Industrial Printing and How Does Ink Selection Affect It

Industrial printing plays an important role in many manufacturing processes, from the production of textiles to custom product labels. Ink selection is a critical factor in achieving the best results. Different ink formulations vary in viscosity and pigment load, as well as their compatibility with ink solvents, making them suitable for different materials and applications. Careful consideration should be given when selecting an ink to achieve the desired result while minimising any impact on production time or cost. Doing so can help ensure an efficient workflow and accurately coded products every time.

Understanding the Different Types of Industrial Printing Inks

There are a number of ink types that are commonly used within Industrial printing. Inkjet printing ink options include water-based, solvent-based, UV cured and speciality ink, which all have their own specific characteristics.

Water Based Ink

Water based ink provides environmental benefits due to its low VOC content, while solvent based ink is most commonly used on non-porous or semi-porous substrates that require higher levels of adhesion.

UV Cured Ink

UV cured ink offers high opacity, has a fast production speed and high scratch resistance, making it ideal for use with thick substrates or challenging applications.

Speciality Ink

Speciality ink such as transpiration resistant or fluorescent inks can also provide unique finishes and effects. Understanding the various ink options available is something that the team at Linx are specialists in, selecting the right type of ink so that you get the best outcomes.

Solvent Based Inks

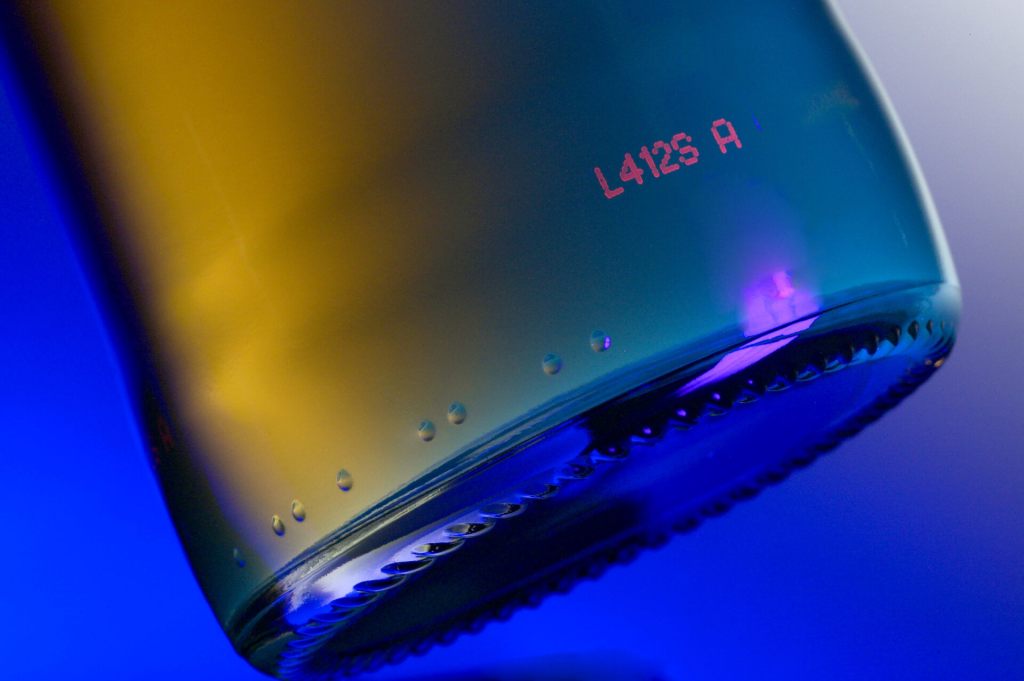

Solvent-based inks are a type of ink that uses organic solvents as a carrier fluid. These inks are commonly used in printing applications where a waterproof and durable print is required, such as in outdoor signage and vinyl graphics. Solvent-based inks have good adhesion to a wide range of substrates and are resistant to fading, abrasion, and water damage.

Exploring the Different Properties of Inks Used in Industrial Printing

Exploring the different properties of inks used in industrial printing is key to achieving the desired results. Inks can be water- or solvent-based, and choosing which type is best depends upon several factors such as the quality of the substrate, drying time, tack level and wet strength. Water-based ink is ideal for low tack applications, because it won’t smudge and it’s easier to clean off than solvent-based ink. On the other hand, solvent-based inks will produce a strong bond with the substrate and are more durable in harsh environments. Other considerations include colour match requirements, longevity of the printed product and whether you need a glossy or matte finish – all of which should help guide your decision on what ink type to choose for optimum results from your industrial printing project.

Product specific needs

The product in question will impact the type of ink that is applicable. Consider how your item will be used, as this will influence which ink type and properties best fit the specific requirements of your application. Factors such as durability should also be taken into account, as this can determine how suitable a particular ink is for a certain use. In addition to these parameters, determining the desired colour accuracy of the finished product should also be factored in.

Other factors to consider

There are a few key factors to consider when selecting an industrial ink – such as viscosity, drying time, odour, and adhesion capabilities – that will determine which is most suitable for each particular need. It’s important to note that certain stocks can require specific inks in order to print correctly and achieve the desired outcome. Whether you are creating packaging, labels or graphics, there is a vast selection of different ink types available on the market, with suitable options available to suit any application.

Ensuring Quality Results with Proper Ink Selection

Whilst speed is a critical element in production lines, quality control is also imperative. Factors like colour accuracy, lightfastness and outdoor durability are especially relevant when choosing the most suitable ink. With such a range of available options – from eco-friendly plant oils-based inks, to more traditional solvent and water-based ones – it’s worthwhile speaking to a specialist to ensure that your ink is matched to your product requirements.

Linx is a renowned manufacturer of industrial printer inks, producing high-quality, reliable and durable inks that are specifically formulated to work seamlessly with our printers. Using Linx ink guarantees optimal printing results with minimal downtime, as it is designed to deliver excellent adhesion, fast-drying, and resistance to smudging, fading and water damage. Linx also offers a wide range of ink colours and formulations to meet the specific requirements of different applications and substrates, making it the best option for anyone looking for high-quality, versatile and cost-effective ink solutions for their Linx printer.