Contract packaging

The Contract Packaging industry is competitive with manufacturers looking for to meet tight timescales and varying customer requirements. To get a competitive edge, co-packers rely on coding printers that provide flexibility, ease of use, and reliability. From handling a range of packing materials to operating to tight timescales and margins, Linx contract packaging printers can solve these challenges.

Linx coders are renowned globally for their reliability and ease of use. Linx printers are rated up to IP65 to give you peace of mind that your contract packaging will maintain quality time and time again. Linx printers and coders offer effecting coding solutions that will ensure your contract packing operation remains competitive.

Request a print sample

See what your code will look like.

To find out more information and

to request your samples with no obligation,

click the button below.

Flexibility

Linx’s range of printers have options to code onto almost any substrate. Primary and secondary packaging can both be coded in one facility, giving co-packers flexibility to keep production moving in-house. Whether a manufacturer is looking for permanent printing solutions or even food-grade inks, Linx industrial marking printers help co-packers adjust to changing customer printing applications.

Ease-Of-Use

Quick and accurate set-up, on-screen service guides, and self-installation are some of the key features that keep Linx’s advanced printing technology user-friendly. With touchscreens standard on all printers, message creation, printing, and routine servicing is kept simple for contract packaging manufacturers.

Low Cost of Ownership

Meet production targets without costly regular maintenance or downtime through extended service intervals. Linx printers only need to be serviced up to once every two years. Keep your printer running, meet customer deadlines, and save money through improved use of consumables.

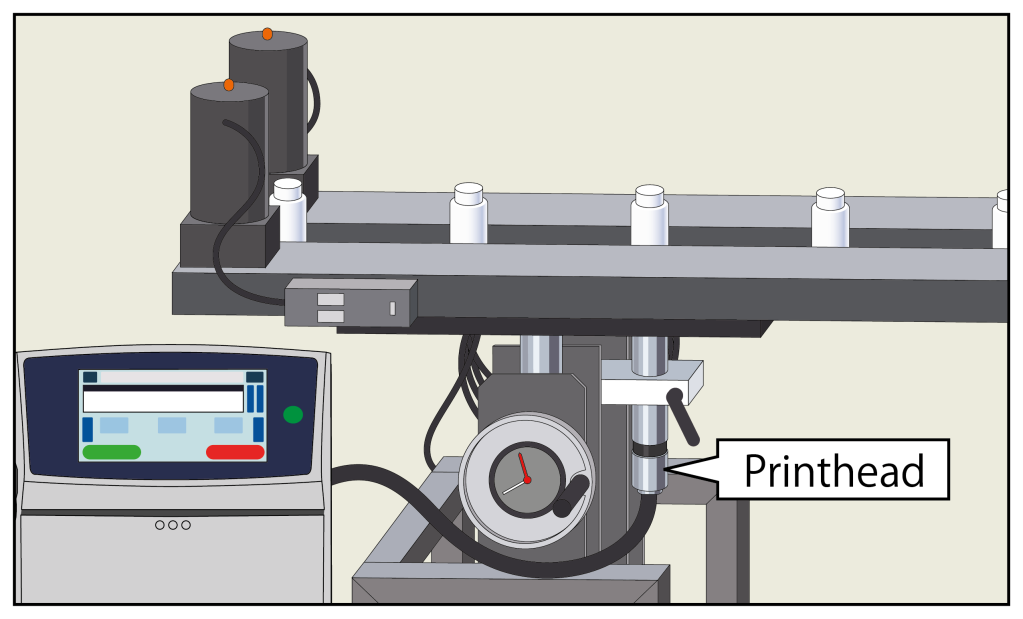

Printing on the Bottom of Bottles

the flexible conduit. The 8900 model can be configured with multiple production lines, making it easy to change setups

and getting the machine printing quickly again after movement.

Contact Us

Why not get in touch with one of our sales reps to talk about how Linx can support your coding and marking needs?

Coders for Contract Packaging

Our coding experts can advise you on the best solution from our range of marking machines for the contract packaging industry. We can help you to reduce waste, maximise production throughput and meet deadlines.

Continuous Inkjet (CIJ) Printers

IP-rated printers with extended service intervals and a range of inks that adhere to most substrates. Easy-to-use and easy to move between production lines, CIJ printers provide security to copackers looking for a standard coding solution.

The Linx 8900 Series printers are designed to make operation and efficiency easier than ever and will support your business with:

- Meeting your output targets

- Reliable, continual operation

- Traceability of your products

- Meeting compliance requirements

- Remote printer monitoring and proactive support

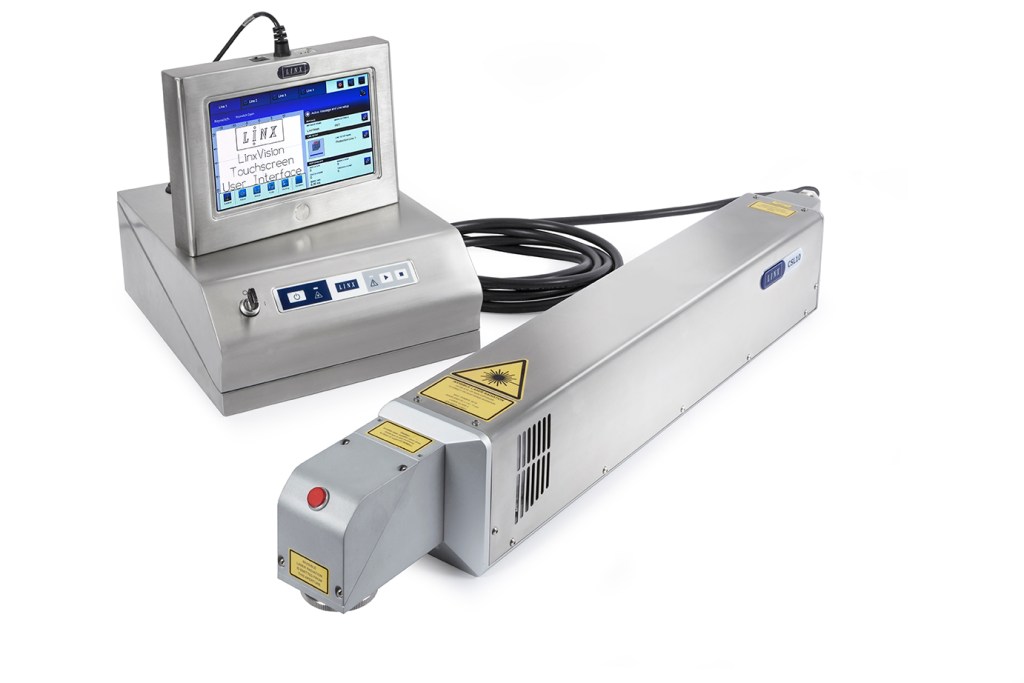

Laser coders

Linx lasers help meet customer requirements with permanent etching onto packaging. Without the use of regular consumables, lasers are cost-effective and equip copackers with a solution for printing traceability information, logos, and other brand requirements.

Laser marking involves no ink in the coding process and therefore no drying time or risk of smudging.

Resources

Competitive Advantage – Effective Coding For Contract Packing

Linx Contract Packing Infographic

Coding Systems for Lean Production White Paper

Linx Contrasting Inks Datasheet

Glowcroft