Fertiliser maker Richfield Fertilisers lowers running costs with Linx 8920

Maharashtra based fertiliser company Richfield Fertilisers Pvt Ltd is one of Maharashtra’s leading distributors & suppliers of fertilisers for the last 15 years.

At its Nashik, Maharashtra facility, the company imports and produces over 30 different products related to the agriculture sector, and distributes them to suppliers throughout India.

Richfield Fertilisers’ Nashik facility has two production lines that each produce over 30 different products, and a dedicated packaging line that processes the specialised fertiliser bags.

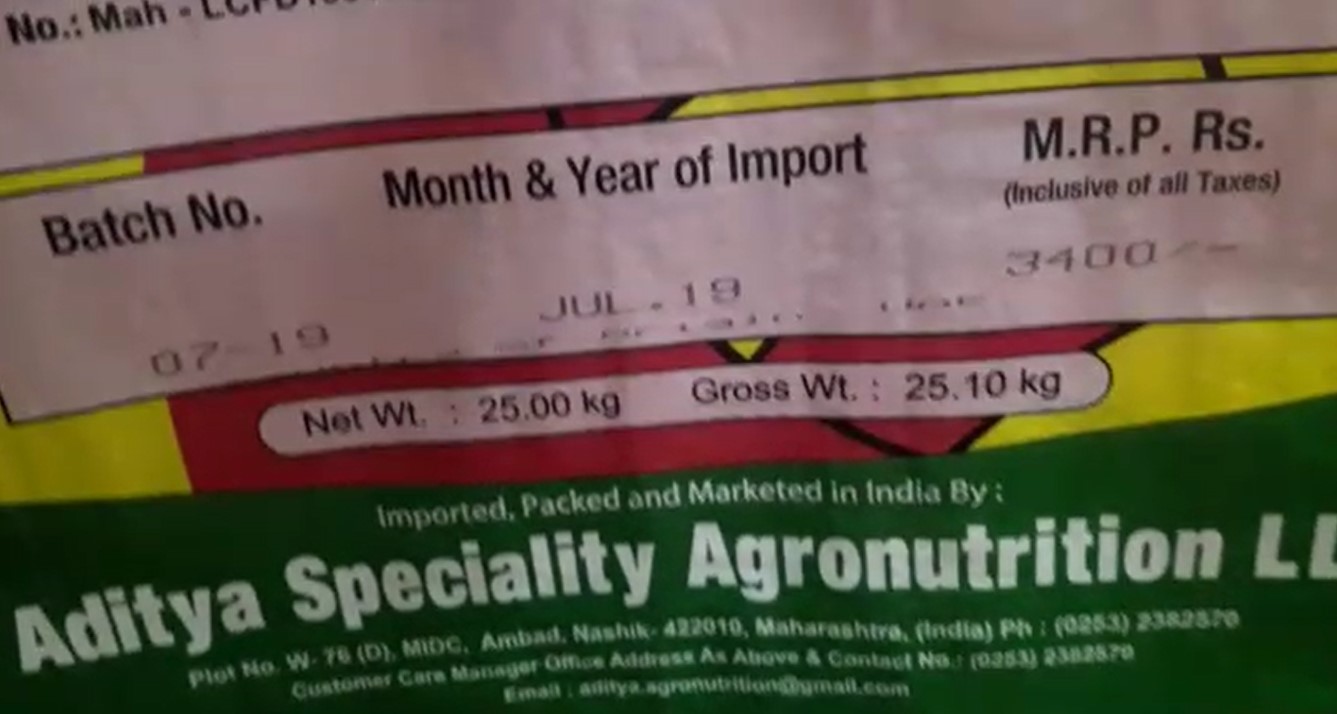

Traceability codes, in the form of MRP, expiry, cost, batch number and logos are applied to the various products for regulatory requirements and for lot traceability.

With regular batch changes and running times of eight to nine hours per day, Richfield Fertilisers required reliable ink jet printers to apply variable data codes.

In the past, Richfield Fertilisers had relied on other manufacturing equipment to handle the coding on their packaging lines, however they were experiencing high maintenance costs and poor service, causing unnecessary downtime. On top of that their per print costs were too high and code changes difficult.

When Richfield Fertlisers management decided to upgrade their machines, they asked Linx Printing Technologies to offer a reliable, cost-effective solution capable of fulfilling the Government norms and regulations.

“We needed a printer with low per print cost, no costly maintenance, easy code changes and good service. The Linx product is very good and service is also good.”

Mr. Amol Loharkar, Deputy Manager, Production

Richfield Fertilisers’ products required three lines of text to be applied, including a batch number, expiry date, cost, logo and MRP.

Linx suggested the 8920 continuous ink jet printers since they provide flexible coding and can print up to six lines across a wide range of production line speeds. The Linx 8920 is reliable and designed to make operation and efficiency easier with minimal maintenance interventions.

The Linx 8920 printers were set up in the production department, and used with a conveyor belt, enabling Richfield Fertilisers’ products to be passed under the printhead and traceability codes applied to the packaging. Operators load the messages and the production head is responsible for total activity.

Since installing two Linx 8920 continuous ink jet printers, Richfield Fertilisers have noticed a significant improvement in running costs. The per print cost and maintenance costs are low, and the machines are easy to use, saving time on product changeovers. Amol also appreciates the modular ink system. Linx’s technology eliminates spillages and ensures the correct fluid type is installed.

In addition to the two Linx 8920 printers installed at the Nashik site, Richfield Fertilisers want to add more. Linx supports them to achieve their goals of continuously increasing uptime and production levels.

“The product is very good and service also good. The printers are very good in performance and run with zero maintenance.”

Mr. Amol, Deputy Manager