Printing on fertiliser products

Fertilisers are produced in an extremely challenging environment. Dust can sometimes corrode the surfaces of production machinery, and together with heat, can have a damaging effect on any sensitive electronics.

Linx continuous inkjet printers are robust machines engineered for such hot, wet and dusty conditions. Our printers operate reliably, are easy to use and have low total cost of ownership.

In addition, due to variations in price and regulations between different states, print messages on fertiliser and agrochemical products tend to change depending on the location and Linx Continuous Inkjet printers offer superior flexibility and reliability for these changing needs.

Coding fertiliser bags and sacks

Linx printers are ideal for marking and coding date and lot codes onto substrates such as plastic bags, laminated labels, PET and HDPE bottles and woven sacks.

Reliability

Linx printers offer customers the option of IP55 & IP65 rated machines which ensures performance in the most challenging environments, and recommended for the fertiliser industry.

Easy to use

Options of 7″ or 10″ touch screen with icons, drag-and-drop field positioning, and zoom function for longer messages. USB port for copy and back-up of message and printer settings, and for easy transfer of messages between printers, and downloading of output and line stoppage logs. Variety of languages supported.

Low Total Cost of Ownership

Simple self-service with up to 18 months between services – no engineer required, only 0.5 litres of ink changed. Solvent consumption as low as 3.5ml/hour*. Printhead cleaning interval up to three months to reduce downtime and fluids consumption

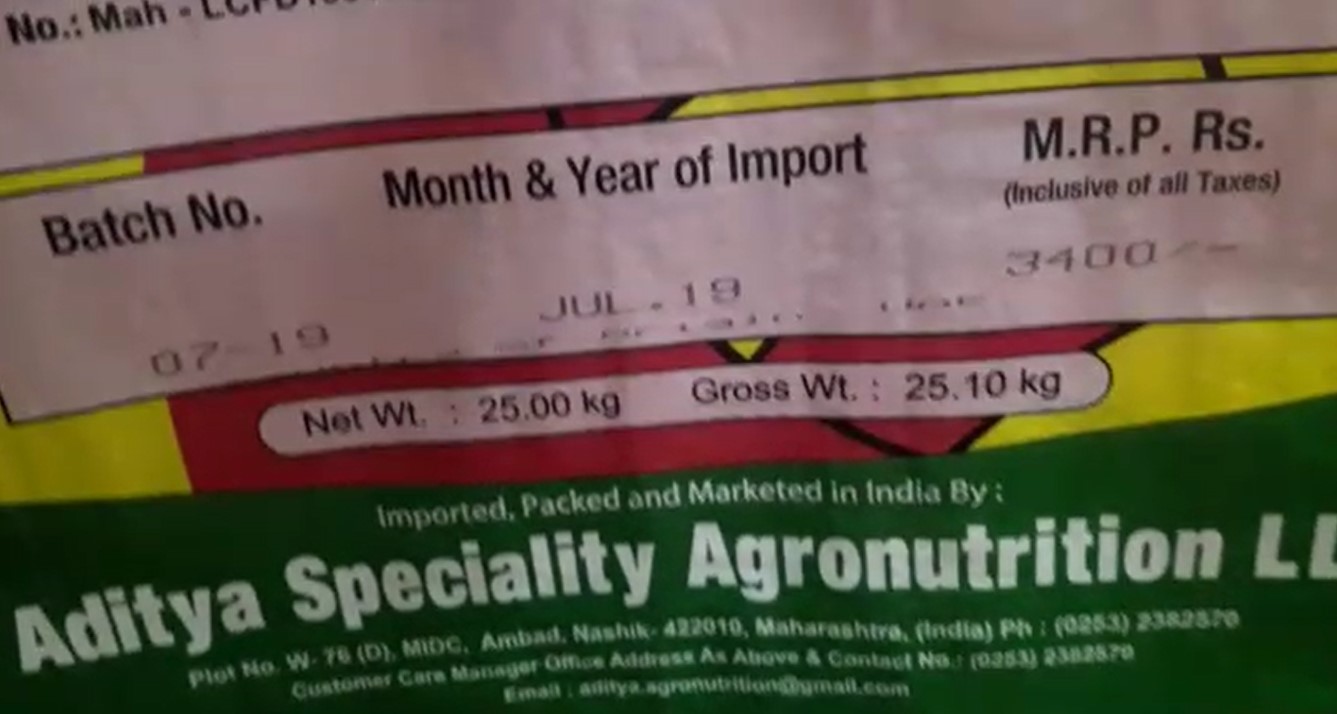

Accurate and consistent marking of batch codes and numbers, lot codes, manufacture dates and MRP also ensures that you keep up with regulations.

Contact Us

Why not speak to one of our sales team about your particular needs?

Richfield Fertilisers Video Case Study

The Linx 8920 CIJ printers being used on a conveyor in the packing and distribution of fertiliser bags and products. The Linx industrial inkjet ensures cost-effective, reliable date and batch marking.

Coding onto bags

The primary challenge in the fertiliser industry is to get prints on fertiliser bags which have diverse composition. Adhesion and durability are the most important criteria for selection of a printing and marking solution. Linx printers have the printers and inks to fulfil such applications.

Coding onto bottles

Traditionally fertilisers are packed in bags. Lately the demand for liquid fertilisers has gained in our country. Many new and first time businesses in the fertiliser industry tend to use bottles for fertilisers. Linx printers are excellent when printing onto HDPE, PET bottles or glass bottles offering superior print quality on rounded smooth surfaces.

Coding on Labels

Linx printers code up to 6 lines of text, barcodes, symbols and numbers up to 20mm high, operating at speeds up to 9.10m/s. Such high speeds are ideal to code and mark information on high speed applications like winder-rewinder machines and direct filling stations. Linx printers deliver superior print quality at high speeds on labels.

We needed a printer with low per print cost, no costly maintenance, easy code changes and good service. The Linx product is very good and service is also good

Mr. Amol Loharkar, Deputy Manager, Production

Coders for Fertiliser Products

Linx 8900 Series

IP55 & IP65 rated printer options

Linx inks range

Range of Linx inks available