Products

Our industrial coding and marking products are renowned for their ease of use, reliability and low cost of ownership.

New Linx 8940 Spectrum

Revolutionary high-contrast pigmented ink printer

Reliable printing with pigmented inks onto surfaces such as plastic cabling, extruded products and coloured glass.

Linx TT Series

Linx Thermal Transfer printers are designed to print on flexible packaging, deliver a low total cost of ownership and increase production line output, an easy to use coding and marking solution.

Linx PrinterNet

See the status of your line and jobs, check your printers’ health, and remotely control them, even when you are limiting access to your site

- Remote access and control of your printers

- Real time email notifications and fluid alerts

- Linx technical support will alert you of any potential issues

- Remote diagnosis of printer issues

Solutions

Discover how our coding and marking solutions can meet your specific industry or material application needs

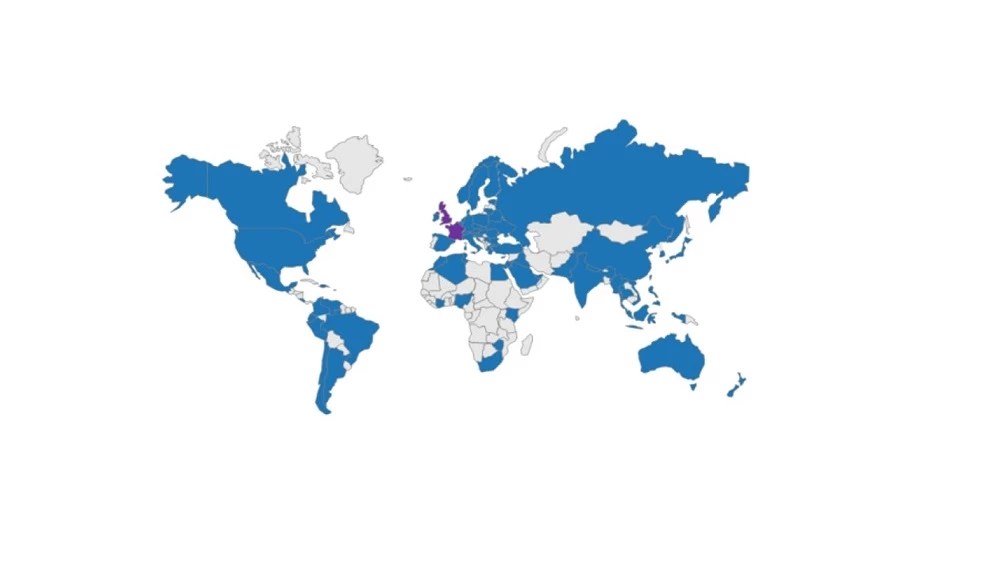

Join our network

Grow your business and provide quality coding solutions in your market, by joining our worldwide channel partner network