Entiris

Entiris is one of the largest employers in the provinces of Flemish Brabant and Antwerp in Belgium. Operating over eight sites and employing over 1700 staff, the company provides customised packaging services for a range of industries including medical devices and electronics.

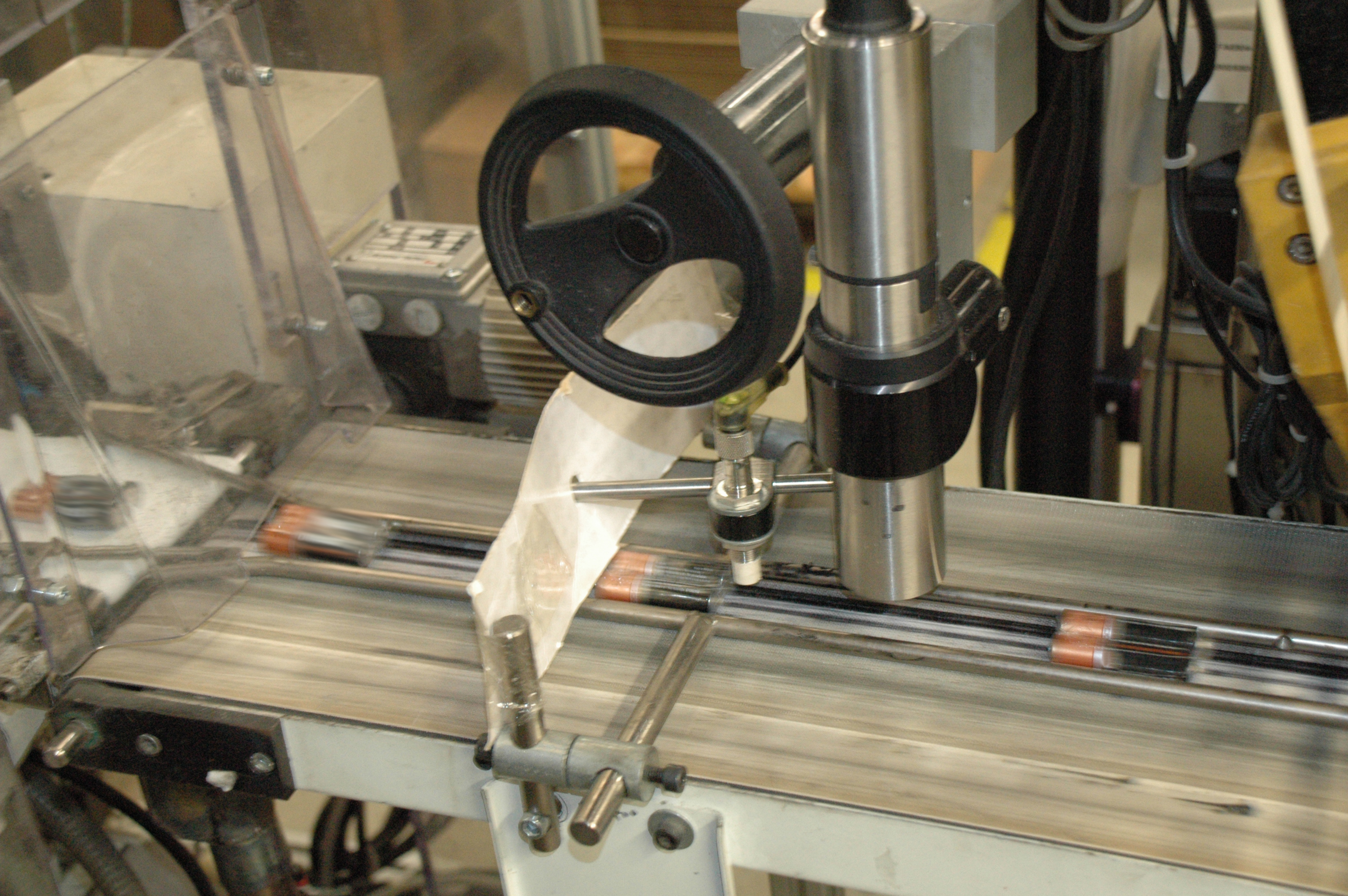

Entiris runs 23 production lines, packing and coding the batteries into both primary and secondary packaging, which includes cardboard cartons, plastic heat-seal packaging and shrink wrap. Entiris initially applied simple, five to six character batch codes to packages of batteries using a dry stamp. However, when the client switched to ten-character coding, the dry stamp method was no longer suitable, plus manually changing all of the dry stamp coders at each batch change was a time-consuming operation. Entiris decided to opt for Continuous Ink Jet printing, and looked to Linx distributor Presa to specify the right solution for their needs.

Presa recommended Linx 7900 CIJ printers for applying the new code across all of the battery packaging. As well as having the flexibility to apply the new codes to all of the packaging types, the printers have brought additional advantages to the company. Coding errors have reduced as the codes are programmed into the printers and only a few fields can be changed.

“We now have great speed and flexibility when we need to change a code on a device”, comments Guy Van Laer, Deputy Director of Technical Production. “To give you an idea: we used to have about two hours to start a line, versus just a few minutes today.” In addition, Linx machines require very little maintenance and production stops are very rare. Entiris can attest to this. “Whether we produce a lot or little, we clean the machines once a month”.

In conclusion, Entiris emphasizes efficiency as a great advantage. “Production planning can now be organized in a much simpler and more efficient way.”