Parilla Fresh Pty

Linx’s distributor, Matthews Australasia Pty Ltd, has installed a Linx TT5 Washdown printer onto form, fill and seal equipment at Parilla Fresh Pty in Australia.

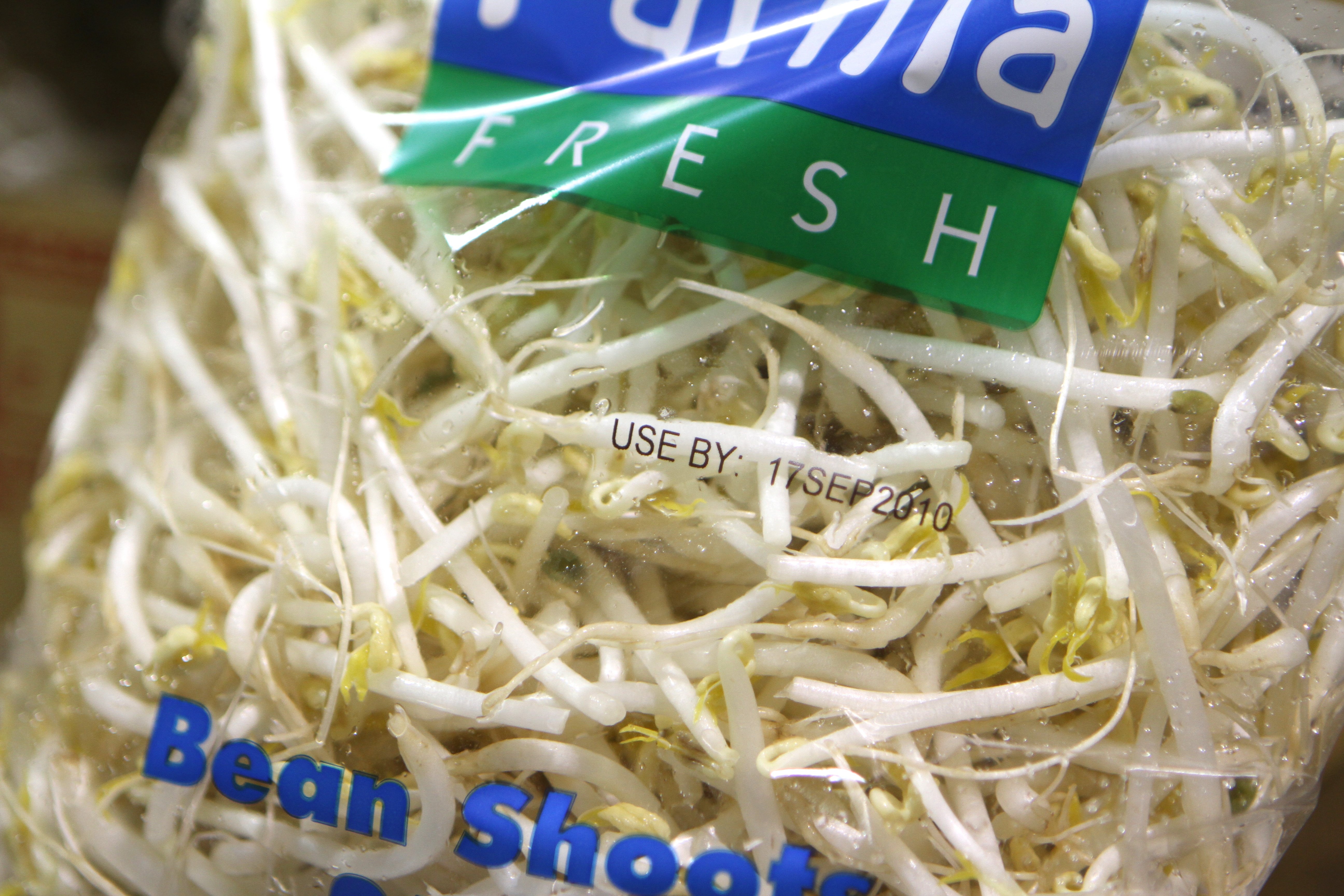

Parilla Fresh grows and sells a wide variety of sprout products, with sprout growing and distribution facilities in Sydney, Australia. It services the Sydney and Melbourne wholesale markets, as well as leading supermarkets 6 days a week.

Parilla Fresh was using hot foil technology for date-coding; the operator had to change the date using pliers, making it difficult and inefficient. Also, the packaging area needs to be washed down everyday to maintain hygiene and is therefore a very wet environment.

The existing hot-foil machine had to be removed from the packaging line before washdown began to prevent water damaging the machine. Both these factors affected the overall efficiency and productivity of the packaging line.

Parilla Fresh needed a highly reliable solution for wet environments, while improving the productivity, quality and efficiency of the packaging line.

The company needed a technology solution that could print the “use by” date clearly onto flexible film before the bags were actually formed, plus provide fast and easy date changeovers. They were also interested in tracking their productivity.

The solution that best fitted Parilla Fresh’s application was a TT5 Washdown thermal transfer overprinter, with IP65 rating for the wet environment. The printer has been installed to work in tandem with the company’s form, fill and seal equipment, printing the “use by” date onto flexible film before the bags are formed.

Ideal solution for wet environments:

- saves time and effort previously spent in removing the printer from the factory floor before wash down

- only the standard print cassette needs to be replaced with the IP cassette to prepare the printer for washdown

Cost-effective solution to improve productivity and efficiency:

- date changes made possible with just a click of a button

- excellent print quality at a smaller font for better ribbon utilisation

- <1mm between prints and longer ribbon cassettes for less frequent ribbon changes

Tracking productivity:

- the printer’s data-capture capability has enabled the staff to accurately check if the right quantities are being processed by keeping a count on the TT5’s display of the number of units the company produces each day

“The TT5 is saving us money. We’re saving labour in not having to remove and replace the machine every day when we hose down; it’s much easier and faster to change the date each day; and we’re not having to constantly eplace ribbons. It all adds up.” — Matthew Szenczy, Production Manager, Parilla Fresh.