Food packaging coding and marking solutions

Our coding and marking solutions help meet a number of challenges faced by the food industry.

Food Safety and Standards Authority of India (FSSAI) is an autonomous body established under the Ministry of Health & Family Welfare, Government of India via the Food Safety and Standards Act, 2006 which is a consolidating statute related to food safety and regulation in India.

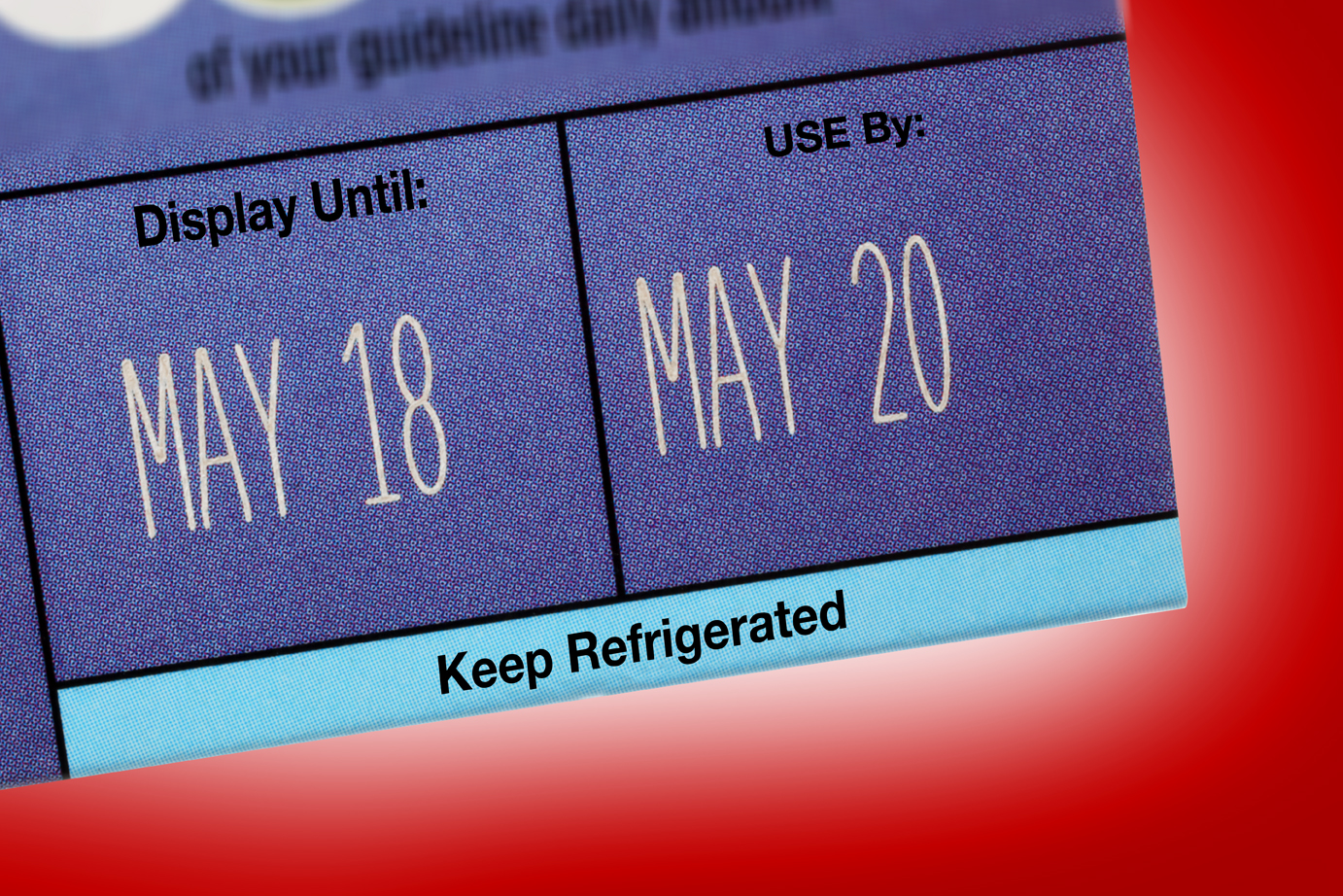

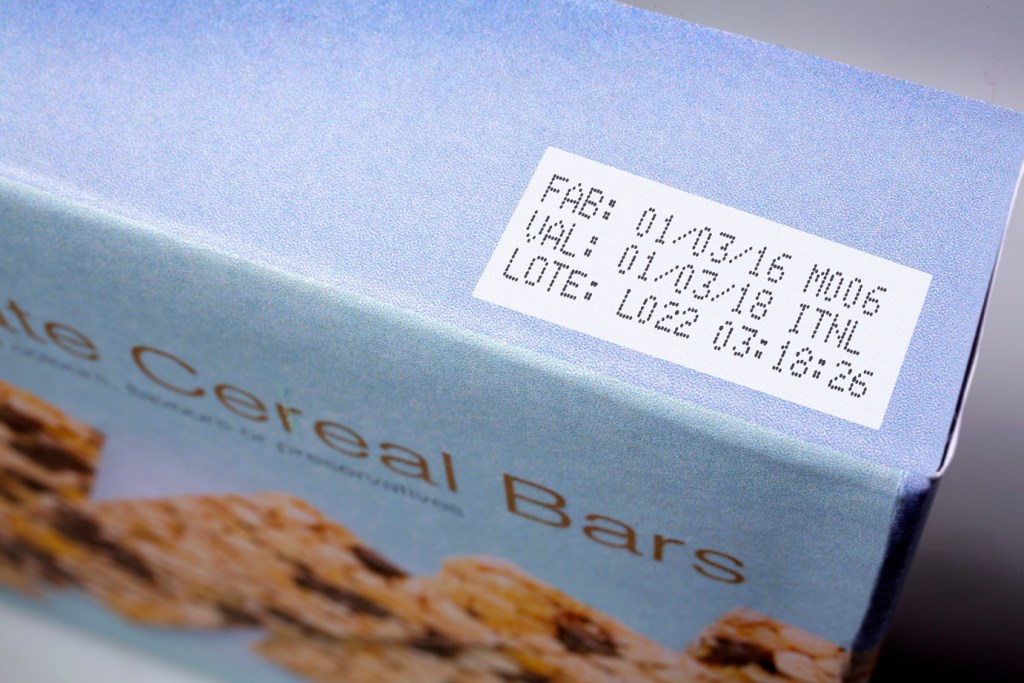

“Food Labeling” serves as a primary link of communication between the manufacturer and consumer and covers both food safety and information of consumer interest. In present time, the industry practice is to put manufacturing date and expiry date at two different places over the pack and it became difficult for consumer to see both at a glance. Hence, the new regulations propose that Date Marking including date of manufacturing and date of expiry must be at one place to make it easily.

These requirements can be easily met by Linx range of Continuous Inkjet printers, Thermal Transfer Printers and Laser coders. You can read the list of regulation changes from FSSAI here. Additional you can read an in-depth analysis of the same on foodsafetyhelpline website.

High quality, legible codes which stay in place throughout the product’s lifetime, help to meet the required food coding and marking standards, and also protect your brand.

Large colour touch-screens with graphical interfaces make code setup and selection quick and error-free, meaning fewer operator errors and product recalls. High speed coding capabilities plus versatile coders with carton coding features for both primary and secondary printing with one printer. While a range of IP ratings for continual, reliable operation in a food coding environment, self-service models requiring no service engineer visits can increase productivity by reducing downtime and maximising line efficiencies.

Our wide range of specialist inks for CIJ printers include plastic adherent inks and low odour non MEK inks.

Our products are suitable for printing date and batch codes, expiry dates and MRP on a full range of packaging materials used by food manufacturers, including paper labels, cardboard and plastic packaging, bottles, and even directly onto food products themselves – such as eggs or cheese.

Coding onto spices packaging boxes┃ Linx 8840 CIJ Printer

Coding onto film for food packets┃ Linx 8800 Series CIJ Printer

Contact Us

Why not speak to one of our sales team about your particular needs?

Printers for coding and marking onto food packaging

Baked Goods

With little chance to rework or recode baked products, first-time code accuracy is important; this includes error-free code setup as well as code legibility and durability during end-use. Linx printers are easy to use without complicated menu systems, making code setup and selection quick and simple.

Continuous Ink Jet (CIJ) – perhaps the most cost-effective choice for baked goods marking and coding, CIJ maintains an important place as it can print on almost any substrate. A wide range of inks are available to use with CIJ printers including coloured inks to ensure legibility on any colour substrate.

Confectionery

The confectionery industry is changing. The trend towards re-closeable bags or tubs of bite-sized chocolate has brought demand for different types of plastic pack, in addition to the traditional paper or card outer wrapper. In this environment mistakes are expensive, both in terms of downtime and wasted product. Coding and marking equipment reliability and versatility are crucial.

Code requirements may be simple and driven by legislation – but stringent food regulations and the importance of accurate labelling information mean this is something manufacturers need to get right.

Meat & Fish

India is the 2nd largest exporter of meat. Selecting the right coding and marking equipment can play a significant part in ensuring processors are ready for the opportunities ahead. Replace illegible ink stamping or branding on animal carcasses with accurate and permanent laser coding.

Packaging of perishable goods such as fish require fast, efficient solutions. Linx printers are designed to deliver reliable operation in the most demanding of applications, including high speed lines, varying pack materials, and wet, cold, saline or greasy environments.

Ready Meals & Snack Foods

Coding and marking in the ready-meals sector places demands on your equipment. Cold, dry and washdown environments bring with them the risk of water ingress to production equipment, affecting reliability and risking downtime.

Linx CIJ printers deliver batch codes from 1 to 5 lines of print, with logos, barcodes and other data printed onto a wide range of packaging materials from paper and card to plastic film.

Linx Laser Coders can deliver even smaller print than CIJ, and at a high resolution. Fitting your batch codes into small areas is not a problem, even on sachets.

Resources

Food Infographic

Special Adherence Inks Datasheet

Food Grade Inks Datasheet

Lean

Batch printing solutions for the meat industry

Coding and marking solutions in the snacks industry

Erlenbacher Backwaren