CODING AND MARKING ON

DIFFERENT MATERIALS

Linx coding and marking equipment can be used for applying various codes onto many substrates in different production environments: wet, dusty or temperature-controlled. Want to find out which printing technology is most suitable for your application? Here are examples of how our continuous inkjet coders, laser markers, thermal inkjet machines and large character printers could be used for different substrates. Find out more about how our printers can mark on your materials.

Applications

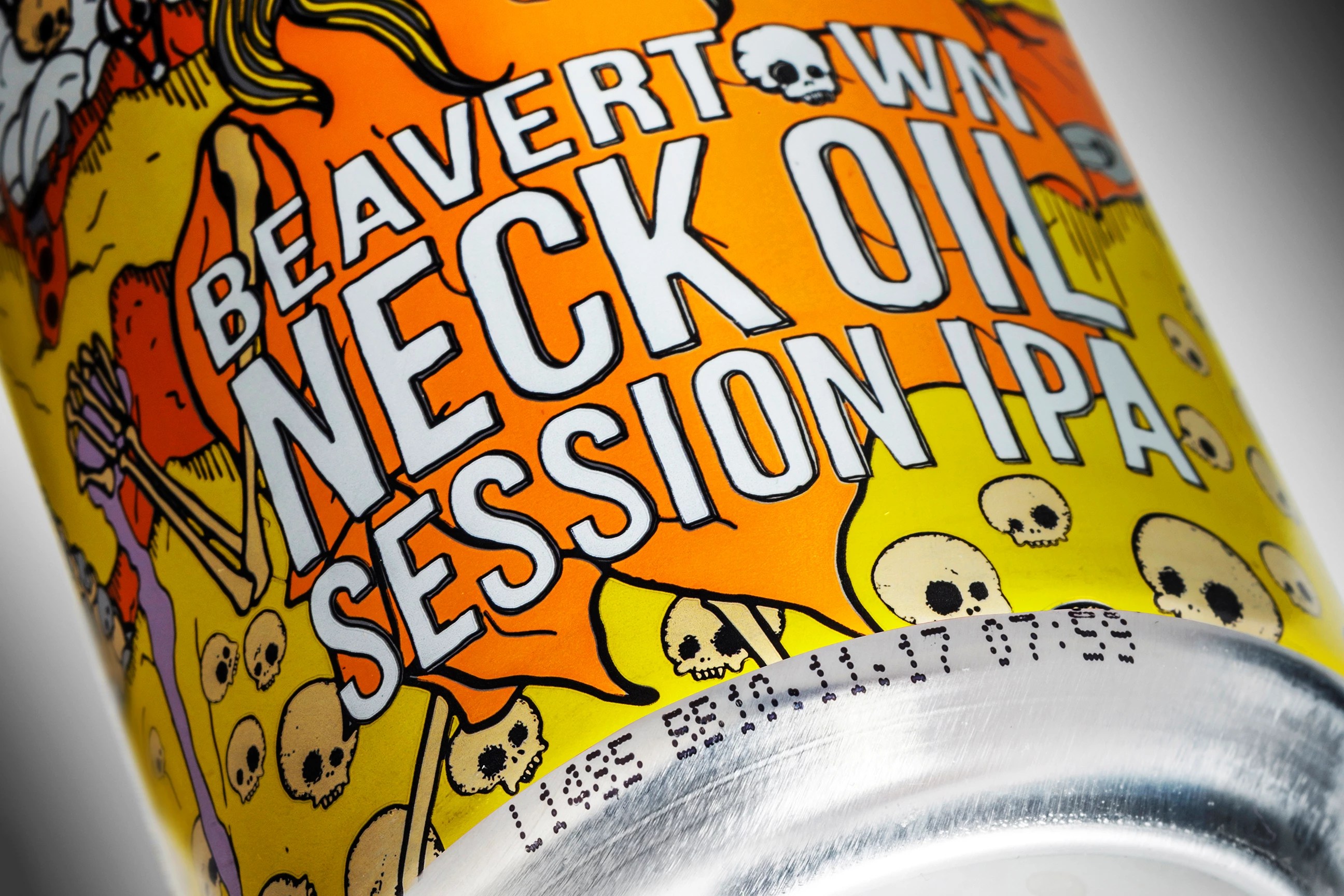

Coated Metal

Coding onto metal bottle tops and curved coated metal can surfaces, with no compromise on reliability or quality of print.

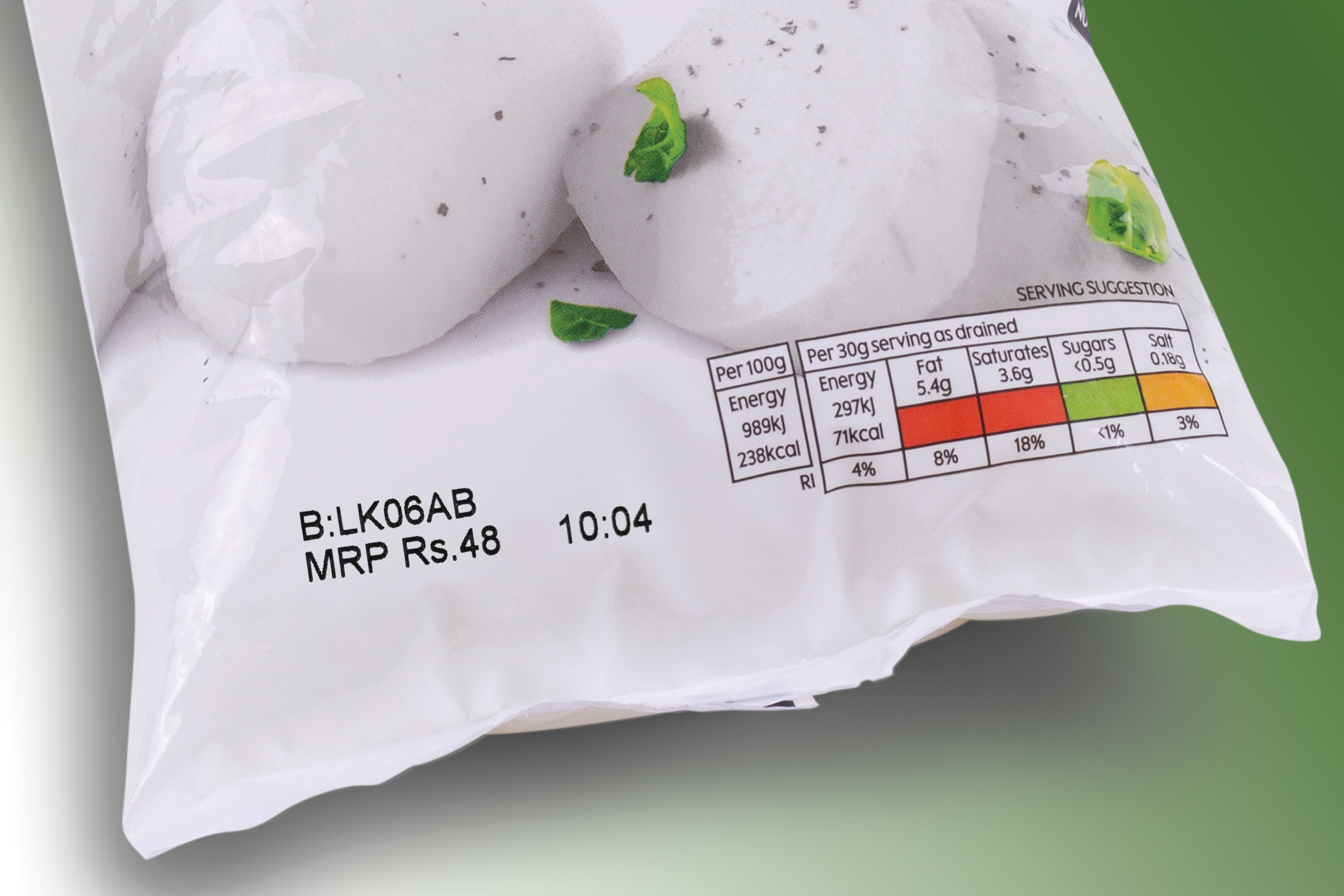

Film Marking

Marking solutions for film packaging printing in industries from meat to dairy, pet food to cosmetics, and more.

Paper and Card

Exceptional quality graphics, text and barcodes onto porous secondary packaging such as bags, trays and boxes.

Printing on Bottles

Solutions for coding on glass and plastic bottles, from household products to drinks and cosmetics.

Printing on Pouches

Printing onto film, plastic and paper pouches, ideal for food and ready-to eat snacks, dairy, seeds and chemicals.