Dairy date marking

Whether coding onto flexible film, tetra pak cartons, pouches, cups and tubs or plastic bottles, Linx printers are designed to be reliable, robust and to print accurate, durable date and batch codes on a wide range of packaging materials. This makes sure that you meet coding regulations, minimise cost and reduce waste.

A rise in health-conscious yet time-poor consumers are influencing current trends in the dairy industry, as such batch printing of dairy products needs to be flexible to cope with the expanding range of product packaging types.

For dairy producers, focus on cleanliness and short product shelf life creates added pressures on the packaging operations. Also you have to factor in changing packaging designs and expanding product flavors and variety, and the increased production changeovers adds further complexity.

We have Continuous Inkjet printers that help add value to your dairy products, and improve traceability.

Printing on dairy packaging products

Linx Printers are ideal for printing date and batch codes onto dairy products such as milk pouches, butter and yoghurts

- Flavoured yogurts

- Skimmed milk

- Ice Cream

- Butter

- UHT milk and juice

- Lassi/Buttermilk

- Milk pouches

Maintain uptime and control costs

Reliable operation in wet or damp production environments is critical, especially on fast-moving production lines. Maintaining uptime is essential for products with a short shelf life, where time to market is restricted and cost control is paramount.

Our CIJ printing solutions can help maximise up time between multiple SKUs with quick, error-free code changeovers while line setups can be stored and retrieved for repeat work.

Drive your OEE with built-in, real-time output measurement features providing clear, on- or off-target alerts.

Our self-cleaning printheads ensure clean startups, first time every time, and deliver consistent code quality while self-servicing and quick, clean cartridge refills keep downtime to a minimum.

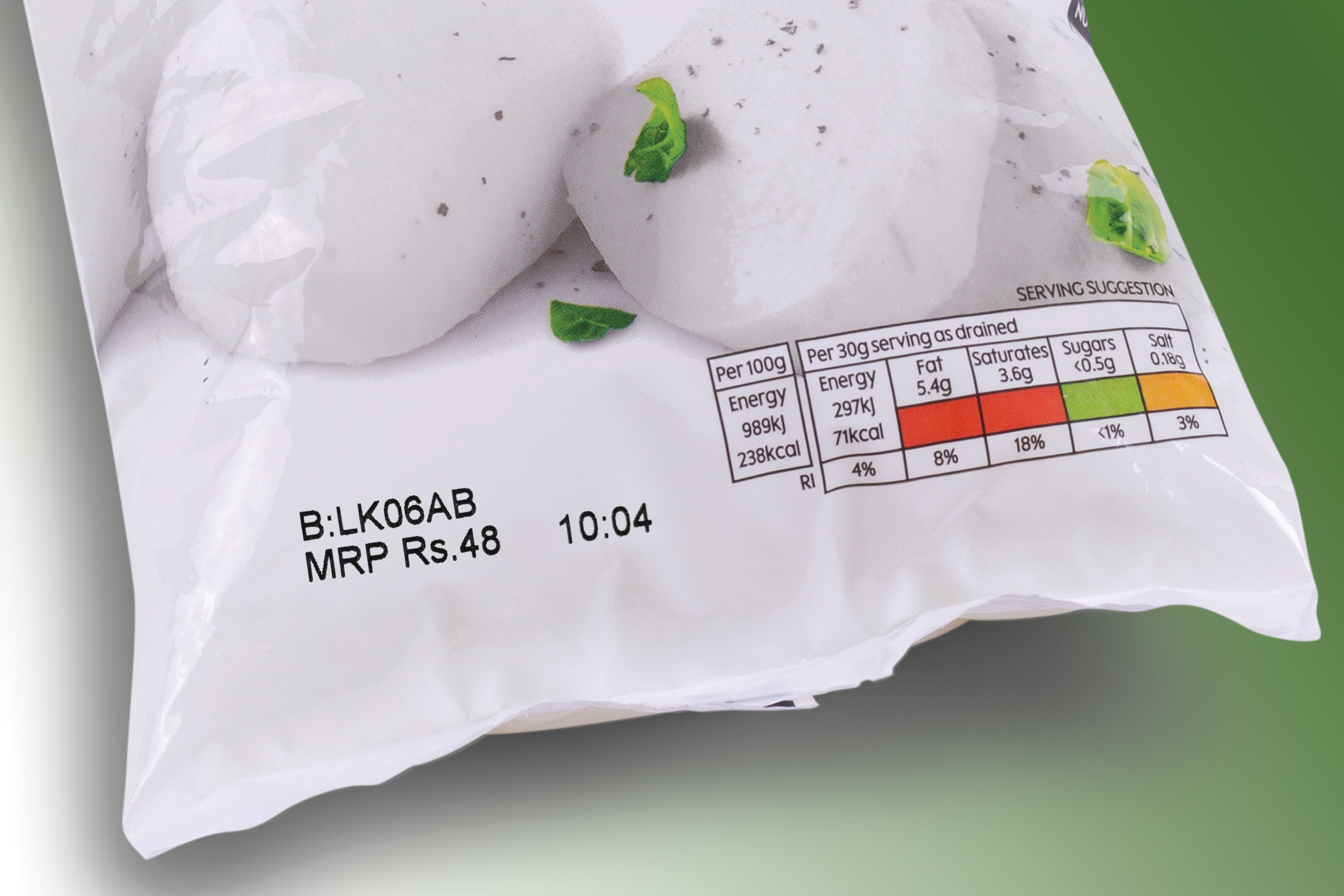

Coding onto milk pouch packaging

Contact Us

Why not speak to one of our sales team about your particular needs?

Quality dairy coding across a range of packaging materials

Plastic, glass and paperboard

Linx laser coders provide a high quality, permanent code. Print directly onto film lids, plastic and glass pots and paperboard cartons.

Jugs, bottles, labels and sleeves

High quality coding directly onto plastic, or onto label or sleeves with Linx CIJ, Laser or Thermal Transfer dairy coding solutions.

Bags, pouches and flexible films

Print accurate batch and date codes onto flexible film packaging with Linx Thermal Transfer printers, CIJ coders and laser marking machines.

Dairy Printing Machines

Thermal Transfer

Ideal for flexible packaging applications, providing high quality date and batch codes onto film pouches and labels. Ribbon saving modes help to deliver a low cost of ownership.

Continuous Ink Jet

Linx CIJ Printing solutions can help to maximise production time between multiple SKUs with quick, error-free code changeovers while line setups can be stored and retrieved for repeat work.

Laser Coders

Linx laser coders are suitable for a wide range of substrates at any line speed. Benefits include increased uptime, higher speed capability and the fact there is no use of consumables.

Resources

Choosing the Best Dairy Batch Printing Solution

Tnuva Dairy

Special Adherence Inks Datasheet

Dairy Coding Considerations