Coding and Marking for Dairy Industry

Reliable & Flexible Dairy Coding

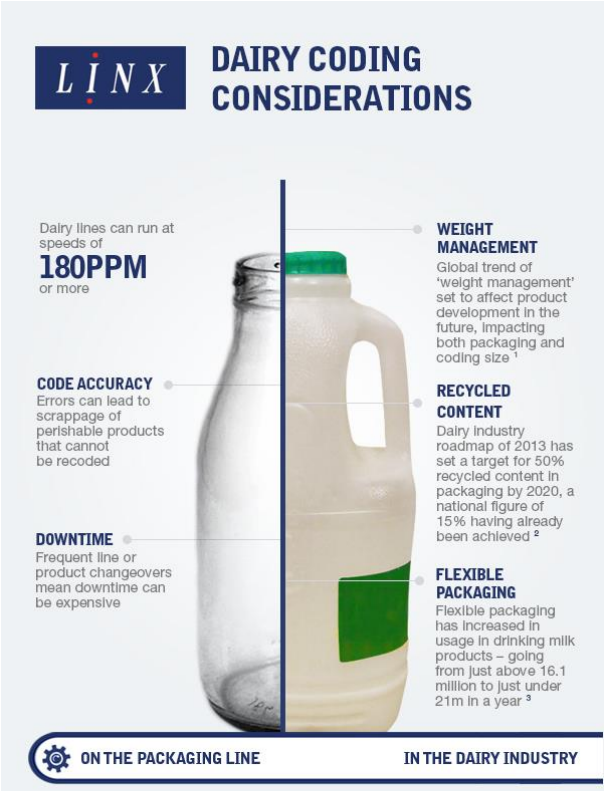

Although the packaging in the dairy industry, through the quality of the pack, the image it portrays and its functionality, can help to establish and maintain consumer confidence, the provision of printed variable information on dairy packaging may seem relatively minor and driven largely by legislation, national and international standards and accreditations.

Nevertheless, although printed codes are a necessity, how they are produced and presented can have a significant impact on a business:

- High-resolution, long-lasting quality printed or marked codes for use-by dates, batch or traceability data will ensure that dairy products meet all the necessary legislation and customer requirements. They will also complement the packaging, making sure the codes do not detract from its overall appearance.

- Printing and marking equipment that is reliable and easy to set up and use will contribute to an efficient operation. Errors can be costly, for example, lost time, lost product, the need for reworks and the possibility of a product recall and retailer fine. This can be particularly critical in the dairy sector with many perishable and short shelf-life products.

- Printing and marking systems can help to minimise product waste and increase manufacturing uptime by reducing stoppages, waste by incorrect coding and change over time.

Whether coding onto flexible film, cartons, plastic and glass containers or bottles, Linx printers are designed to be reliable, robust and to print accurate, durable codes on a wide range of packaging materials. This makes sure that you meet coding regulations, minimise cost and reduce waste.

Maintain uptime and control costs

Reliable operation in wet or damp dairy production environments is critical, especially on fast-moving production lines. Maintaining uptime is essential for products with a short shelf life, where time to market is restricted and cost control is paramount.

Linx coding and marking solutions enable you to meet coding regulations, reduce waste, maximise your production throughput and meet deadlines.

Quality dairy coding across a range of packaging materials

Plastic, glass and paperboard

Linx laser coders provide a high quality, permanent code. Print directly onto film lids, plastic and glass pots and paperboard cartons.

Jugs, bottles, labels and sleeves

High quality coding directly onto plastic, or onto label or sleeves with Linx CIJ, Laser or Thermal Transfer dairy coding solutions.

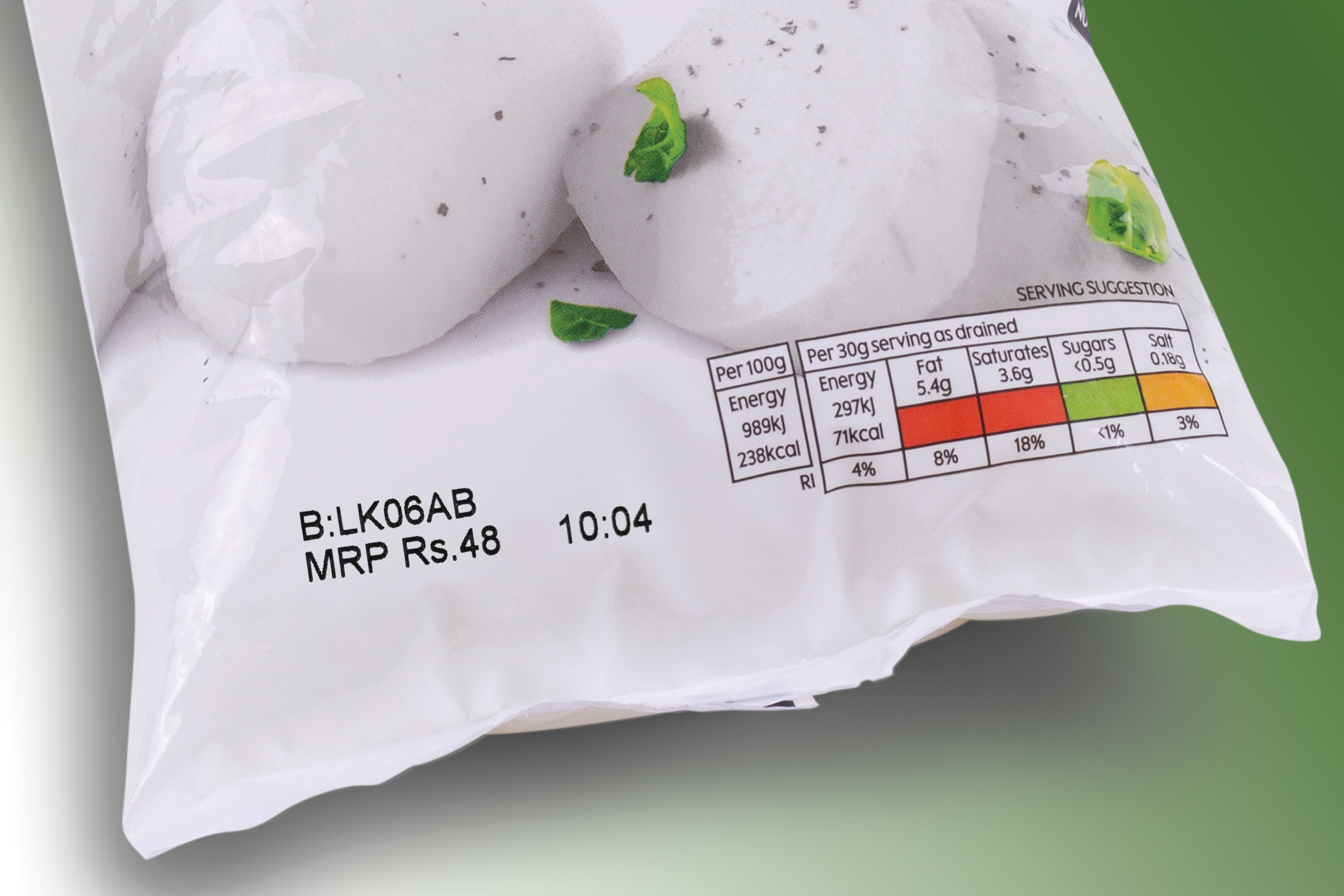

Bags, pouches and flexible films

Print accurate batch and date codes onto flexible film packaging with Linx Thermal Transfer printers, CIJ coders and laser marking machines.

Contact Us

Why not get in touch with one of our sales reps to talk about how Linx can support your coding and marking needs?

Printer Types for Dairy Industry

For the dairy industry, the key drivers for dairy printing and marking requirements are code accuracy and durability, along with ease of set-up and use.

As part of the selection process, the speed of the line and the substrates to be printed onto is critical. It is important to have each material type sample printed to ensure legibility, particularly if a range of different colours is involved.

The majority of dairy code requirements are reasonably simple at present, but future food labelling legislation always has an element of uncertainty. Choosing a future-proof printer, which allows add-ons to be integrated at any time, will enable dairy manufacturers to react quickly to changing trends, customer demands or legislation without having to invest in new equipment.

The overall Cost of Ownership of any new machine purchase should be investigated. This takes into account both the initial price and factors such as reliability and the cost of consumables over the machine’s lifetime. Frequent breakdowns may negate any benefits of a lower purchase price. Leasing and rental options may also be worth exploring.

Continuous Ink Jet (CIJ) printers

CIJ can print on almost any substrate, and there are a wide range of inks available. CIJ can print from one to multiple lines of text and simple graphics on line speeds of up to 6.25m/s for a single line of code.

The compact printhead can be situated above, beside or beneath a production line or traverse from side to side across the line. With lighter models, the CIJ printer is capable of being moved quickly from line to line and is fast to install and set up. The technology can provide the ideal solution to enable start-up and growing businesses to move from manual coding to digital printing methods in order to produce the type of quality codes demanded by the retail sector.

Linx CIJ Printing solutions can help to maximise production time between multiple SKUs with quick, error-free code changeovers while line setups can be stored and retrieved for repeat work.

The Linx 8900 Series printers are designed to make operation and efficiency easier than ever and will support your business with:

- Meeting your output targets

- Reliable, continual operation

- Traceability of your products

- Meeting compliance requirements

Laser coders

Laser marking involves no ink in the coding process and therefore no drying time or risk of smudging.

Laser coders are suitable for a wide range of substrates at any line speed. Benefits include increased uptime, higher speed capability and the fact there is no use of consumables.

Steered beam laser systems are highly versatile as they provide clear, consistent and perfectly formed characters in a variety of fonts and message formats, and enable the use of high-quality graphics and logos over relatively large print areas.

They are particularly suitable where high-quality codes are required, for example, to blend in with the style of pre-printed packaging.

Advances in technology and efficiency have led to a significant reduction in the initial purchase price. In addition, the low cost of ownership due to no consumables and relatively low maintenance means laser coders are a viable choice for many dairy applications.

- Minimal maintenance, low downtime, high-speed capability and no consumables – cost-effective solution

- Codes can be incorporated within a pre-printed packaging

- Highly versatile as they provide clear, consistent and perfectly formed characters in a variety of fonts and message formats, even over relatively large print areas

Inks and Solvents for Dairy Industry

The specifics of using inks and fluids in the dairy industry means that a variety of them could be needed to cater for various production needs: wet, cold environments, food safety standards, etc.

Linx offers a variety of inks and solvents to suit even the most demanding environments and standards. These include:

- inks of different colours to ensure legibility;

- food grade inks for applications where the code may come into contact with the product itself;

- fast-drying inks;

- and ones that ensure the codes do not rub off, even when there is moisture on the packaging.

Resources

Special Adherence Inks Datasheet

Milk Bottle

Get the cream of the crop with superior dairy coders from Linx UK

Choosing the Best Dairy Batch Printing Solution