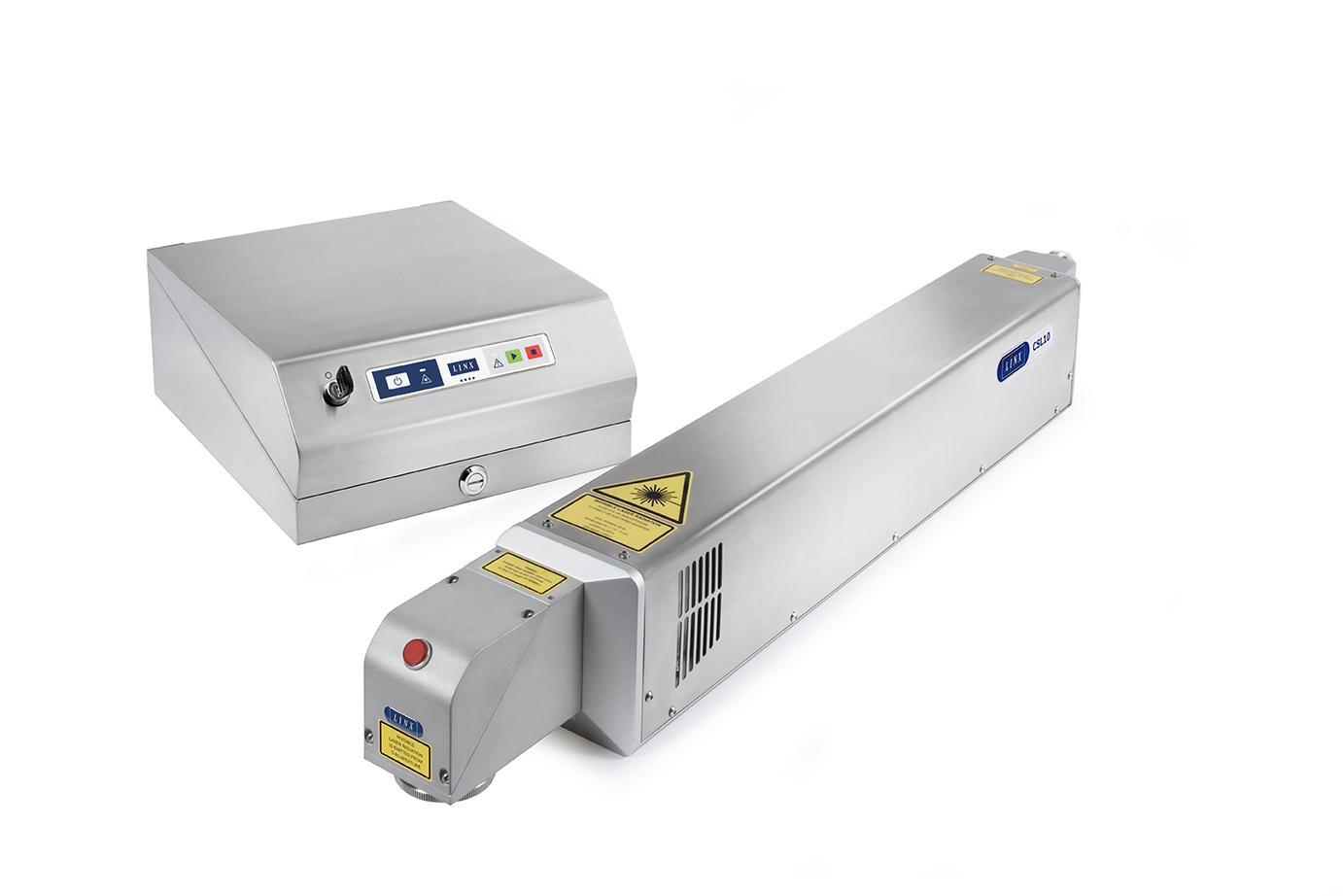

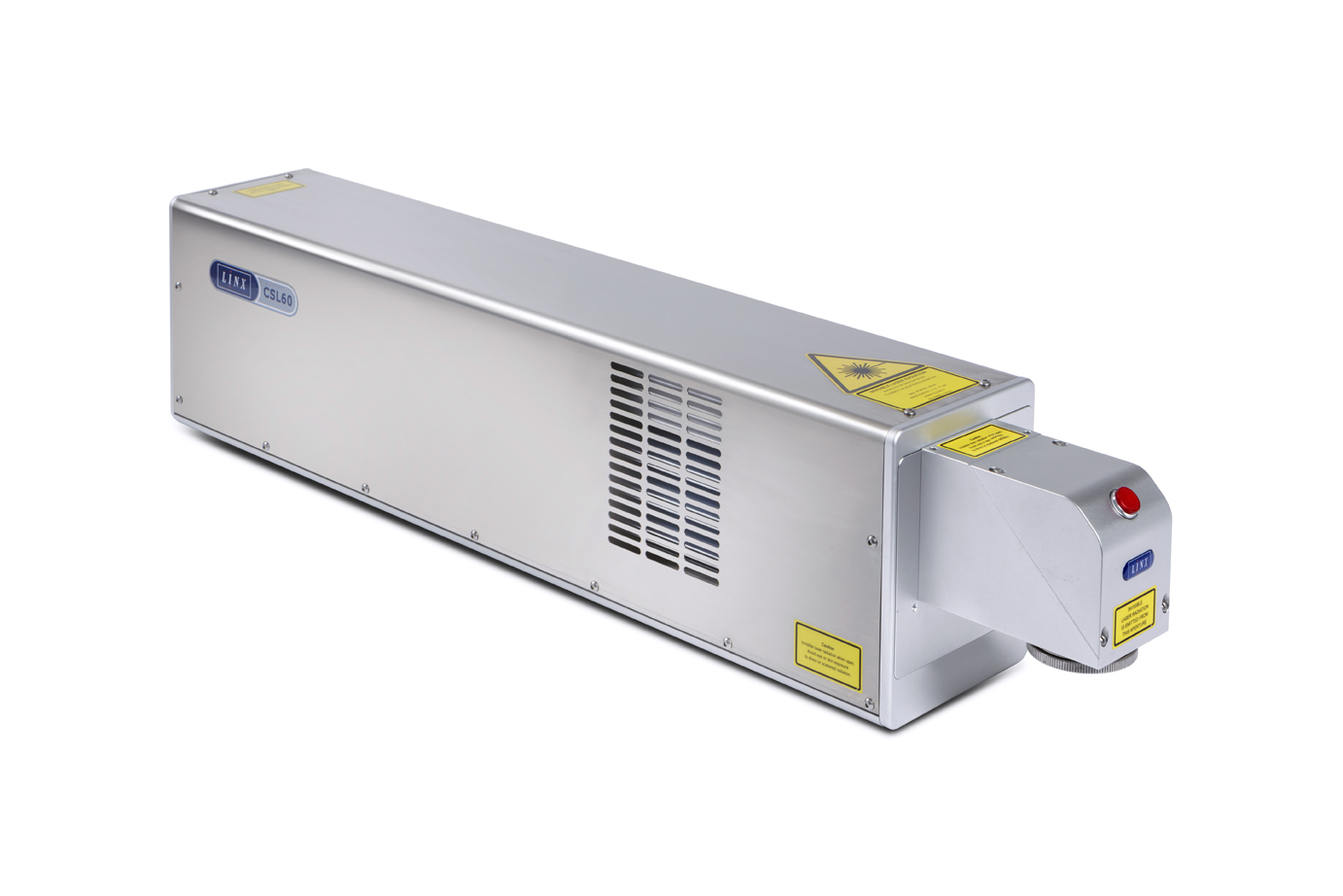

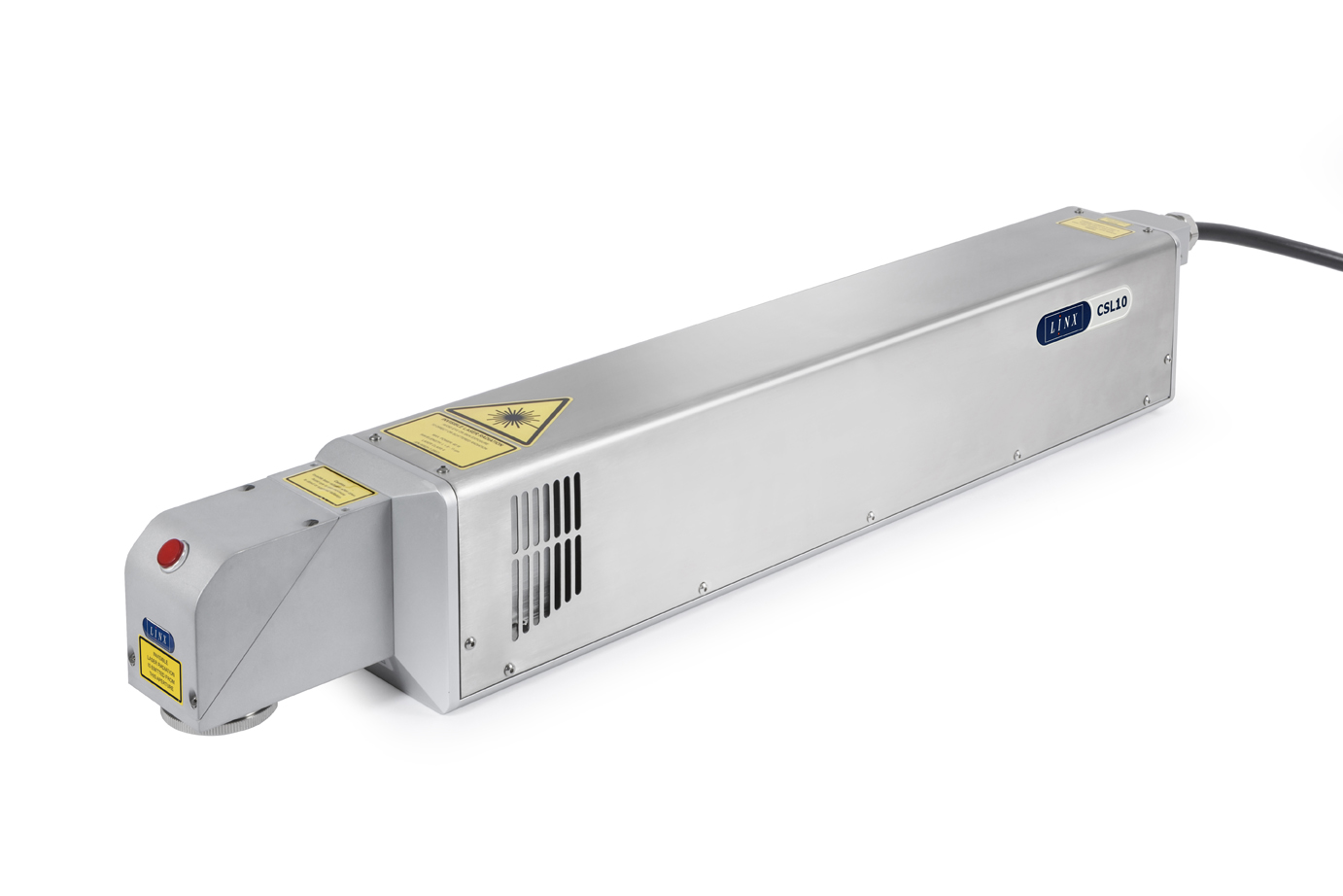

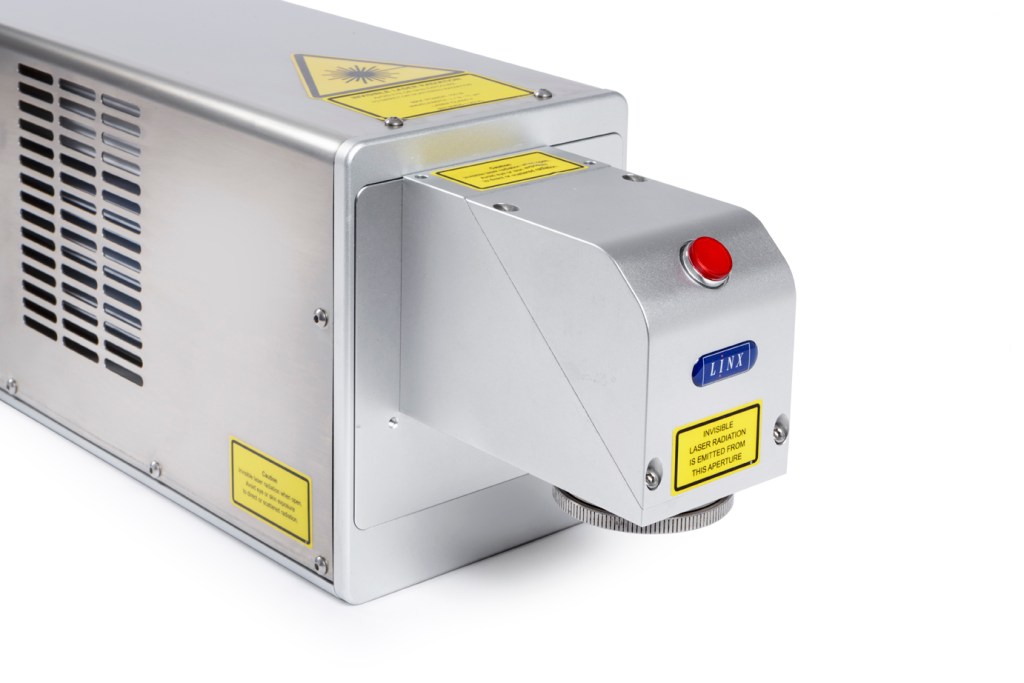

Linx CSL60

Complex coding applications on high speed lines

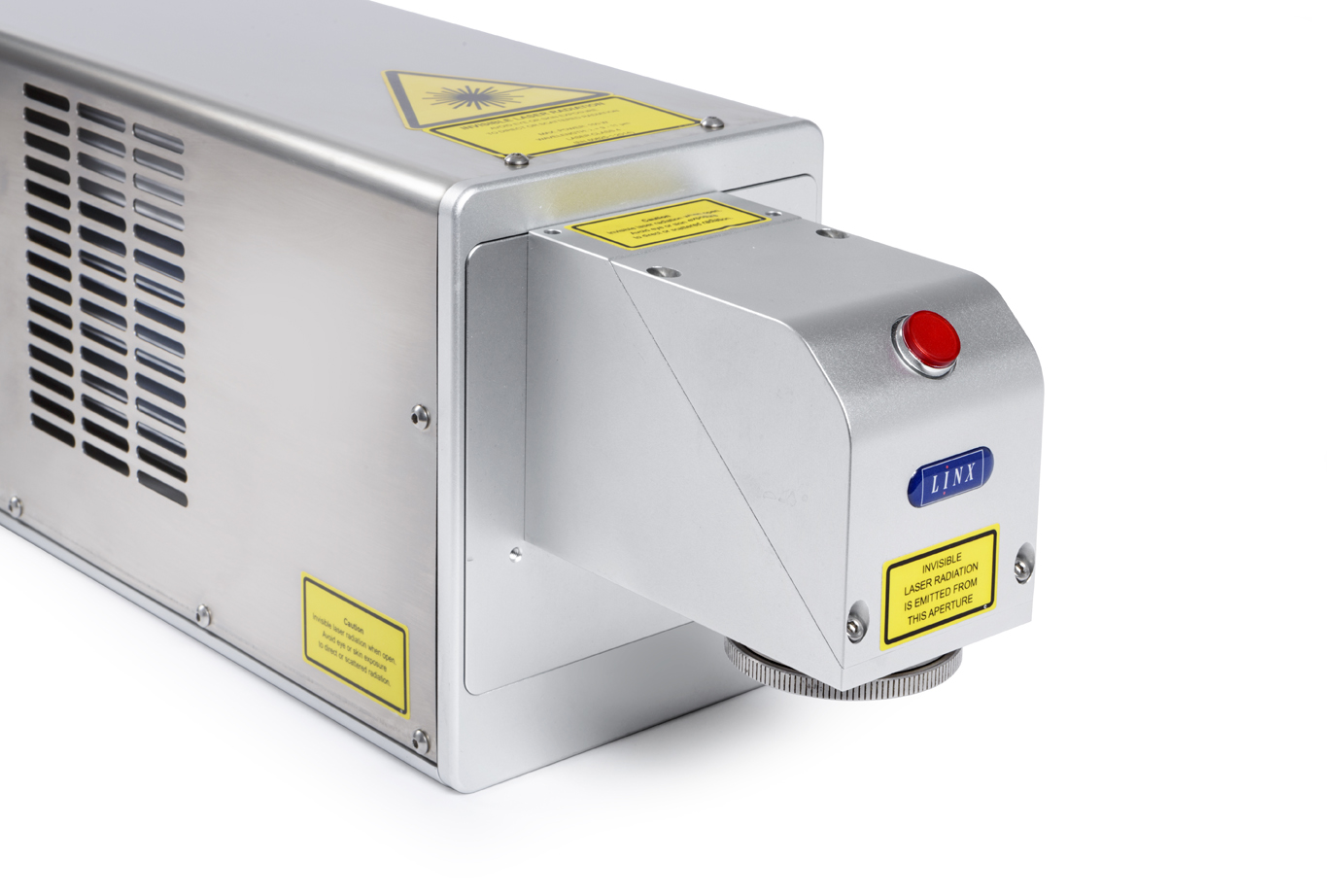

The Linx CSL60 Laser System marks complex codes at a high resolution onto high-speed lines. The 60 W laser power combined with a powerful processor allows coding onto hard to mark materials such as glass and rubber. Full system IP65 rating makes it a reliable coding solution for harsh production environments such as beverage, automotive or extrusion.

Key benefits

Easy to use

- Easy message creation and management of printing parameters with the large colour LinxVision® Touch Screen, and LinxVision software

- Easy line integration – detachable marking head with quick disconnect cables

- Multiple beam delivery options allow for coding in any orientation

- Reduce your coding errors and meet coding regulations with password controls that can restrict access to qualified personnel only

Meet production targets

- A powerful, four-core processor allows printing of complex messages – including 2d barcodes, QR codes and logos – on fast lines with no compromise on code quality

- Code up to 70,000 bottles per hour*

- Reduce running costs and delays with 45,000* hour tube life – one of the longest on the market

- Service intervals typically twice that of the industry standard

- No expensive factory air for cooling

Print in more applications

- High power 60 W laser tube for coding onto hard materials such as glass, rubber and HDPE

- Over 20,000 different configurations to economically meet your coding requirements

- Wide web applications for large area coding or multiple lines of products

- Crisp, clear coding onto cold glass bottling lines, at high speed, with VisiCode®, a unique set of parameters

- Flip, mirror or curve text – easily code onto difficult shapes

*tube life and line speed are application dependent

Resources

CSL60 video

CSL60 Datasheet

VisiCode Datasheet

Laser Coding Solutions Brochure

How Linx Laser Solution Can Help Your Business

Laser Marking Technologies

Technical Specifications

Printing capability

- 60 W CO2 scribing laser coder

- Line speed – code up to 2100 characters/second; 70,000 bottles/hour; 900m/min

- Maximum code height – 601mm

- Marking field size – up to 440 mm x 601 mm

- Laser wavelength – 9.3 μm or 10.2 μm or 10.6 μm

- Laser tube warranty – 2 years

- Spot size – from 0.12 mm to 1.65 mm

- Print rotation – up to 360°

- Marking head rotation – up to 360°

- Code options – Date, time, static text, variable text, serial numbers, shift codes, increment/decrement (batch count), 1D/2D barcodes, graphics and logos, Julian date, Custom date and time formats, 2D codes including DotCode.

- IP rating – full system IP65 rated as option; IP54 as standard.

- Air cooled for both IP54 and IP65 variants.