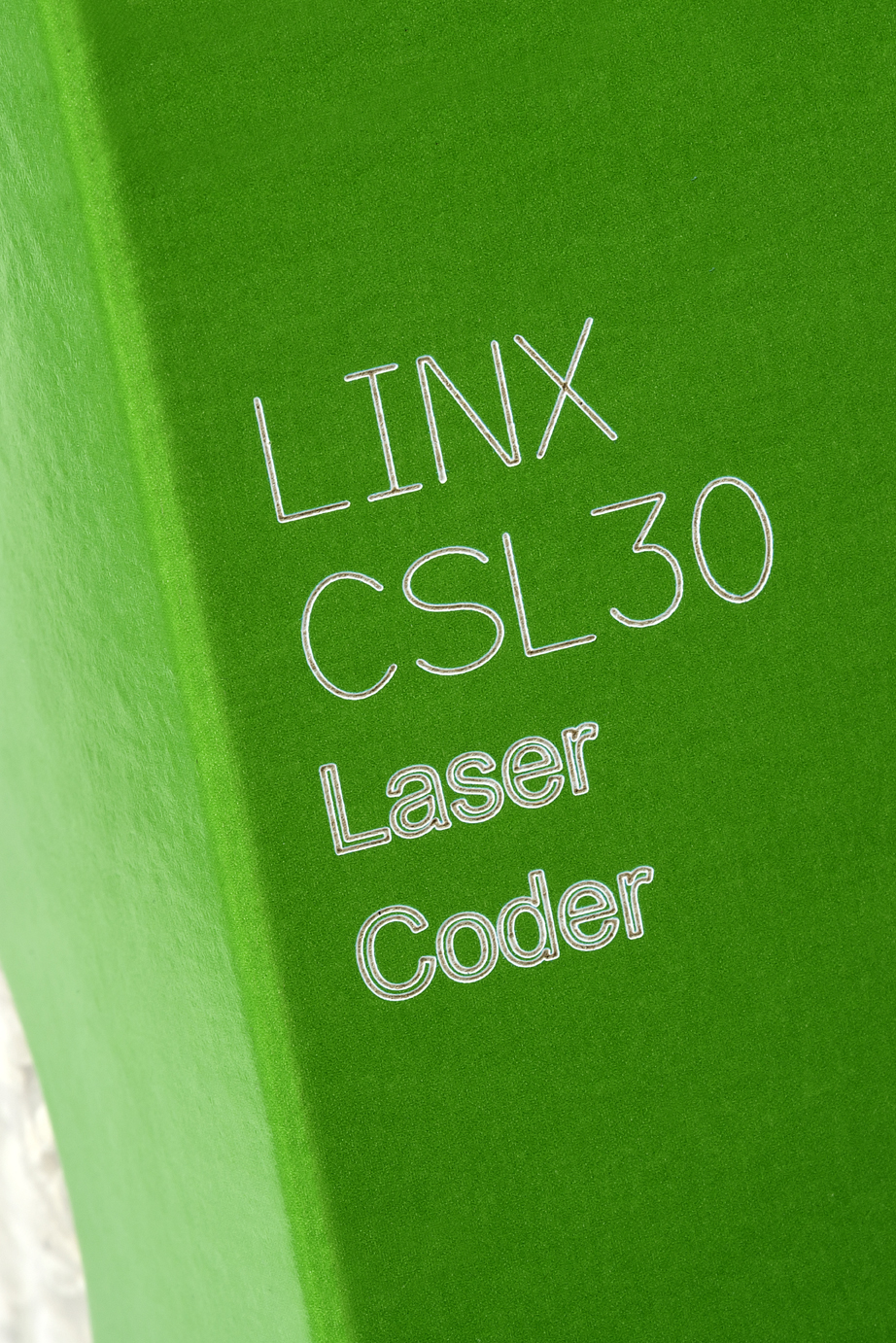

Linx CSL30

Largest marking area in its class

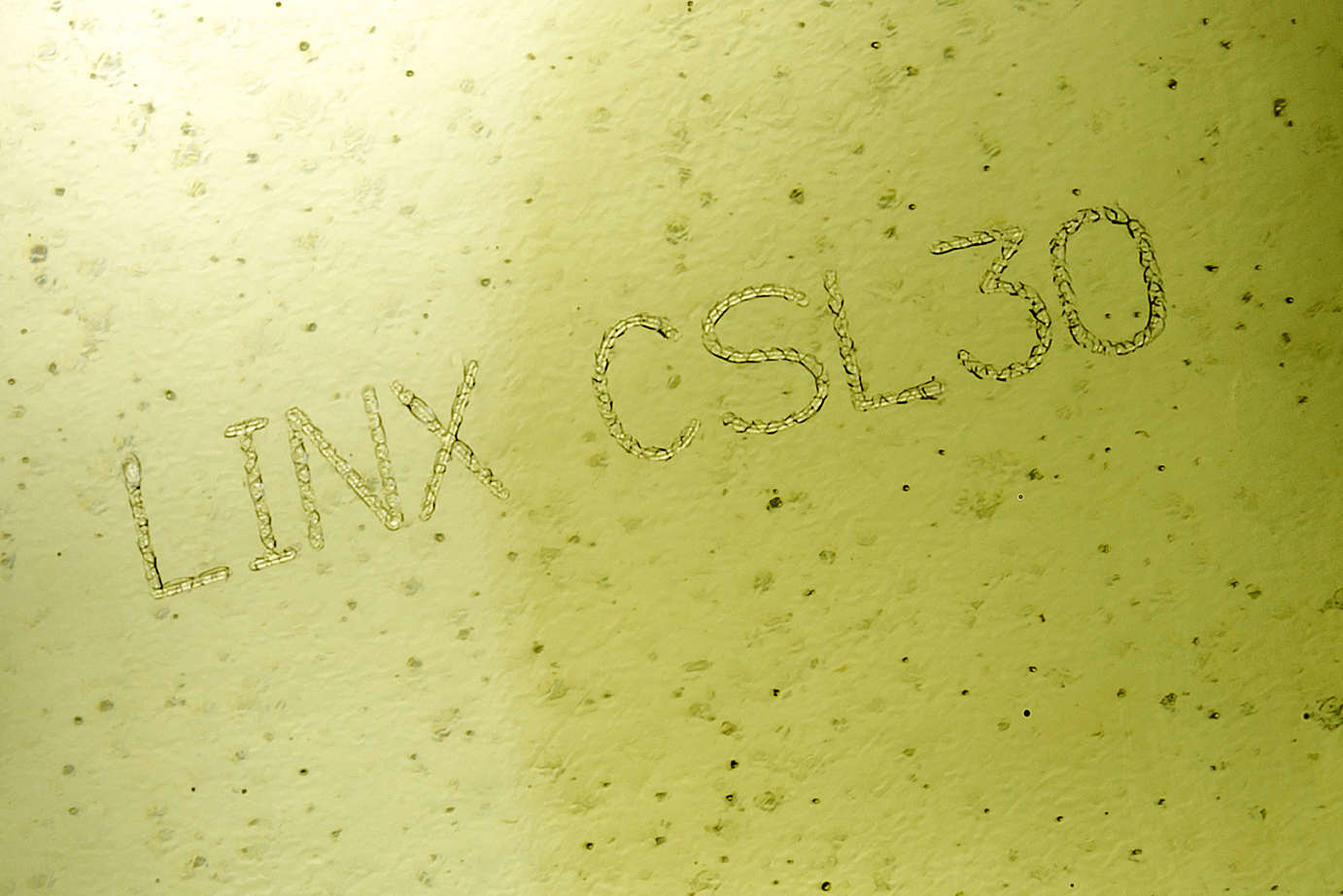

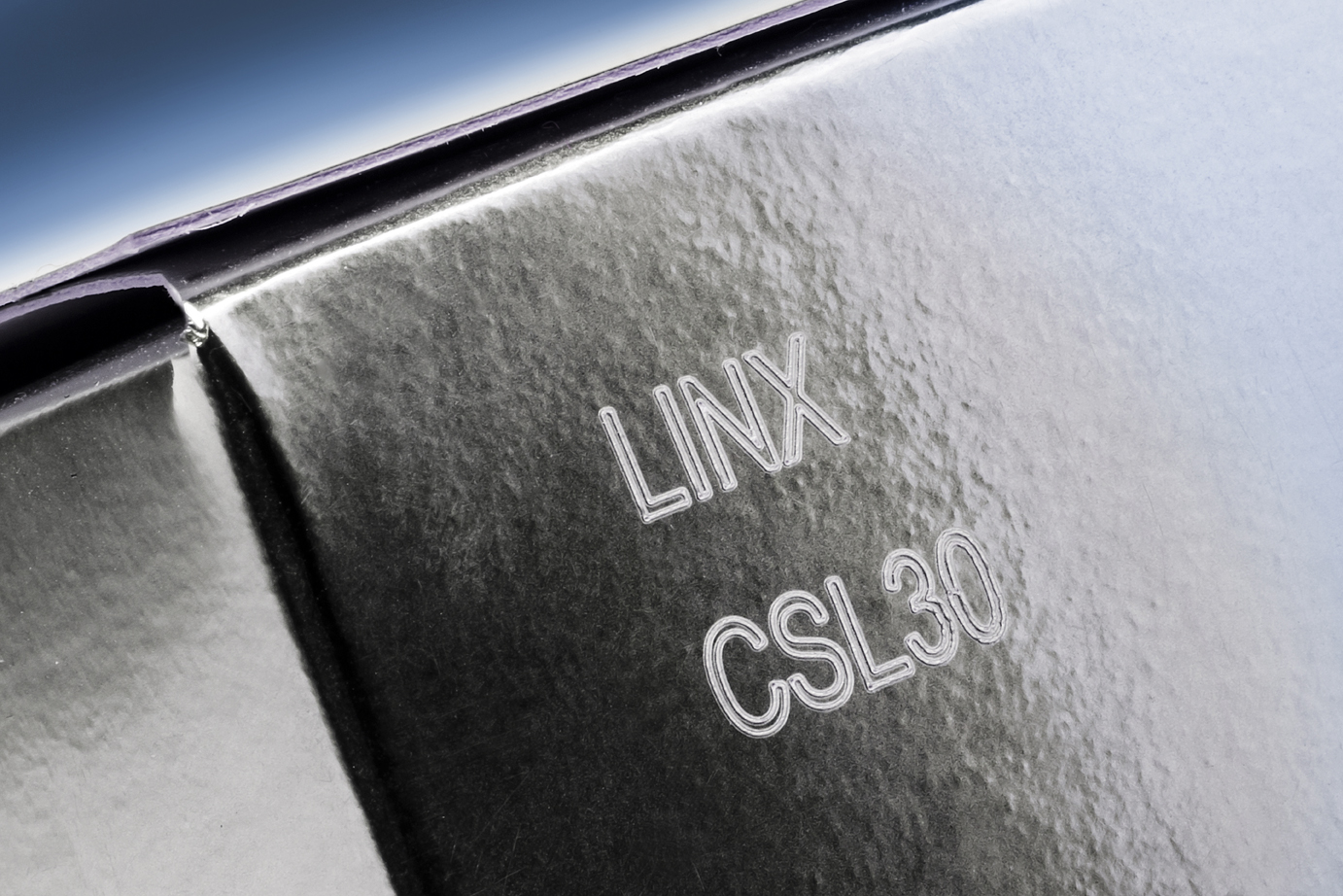

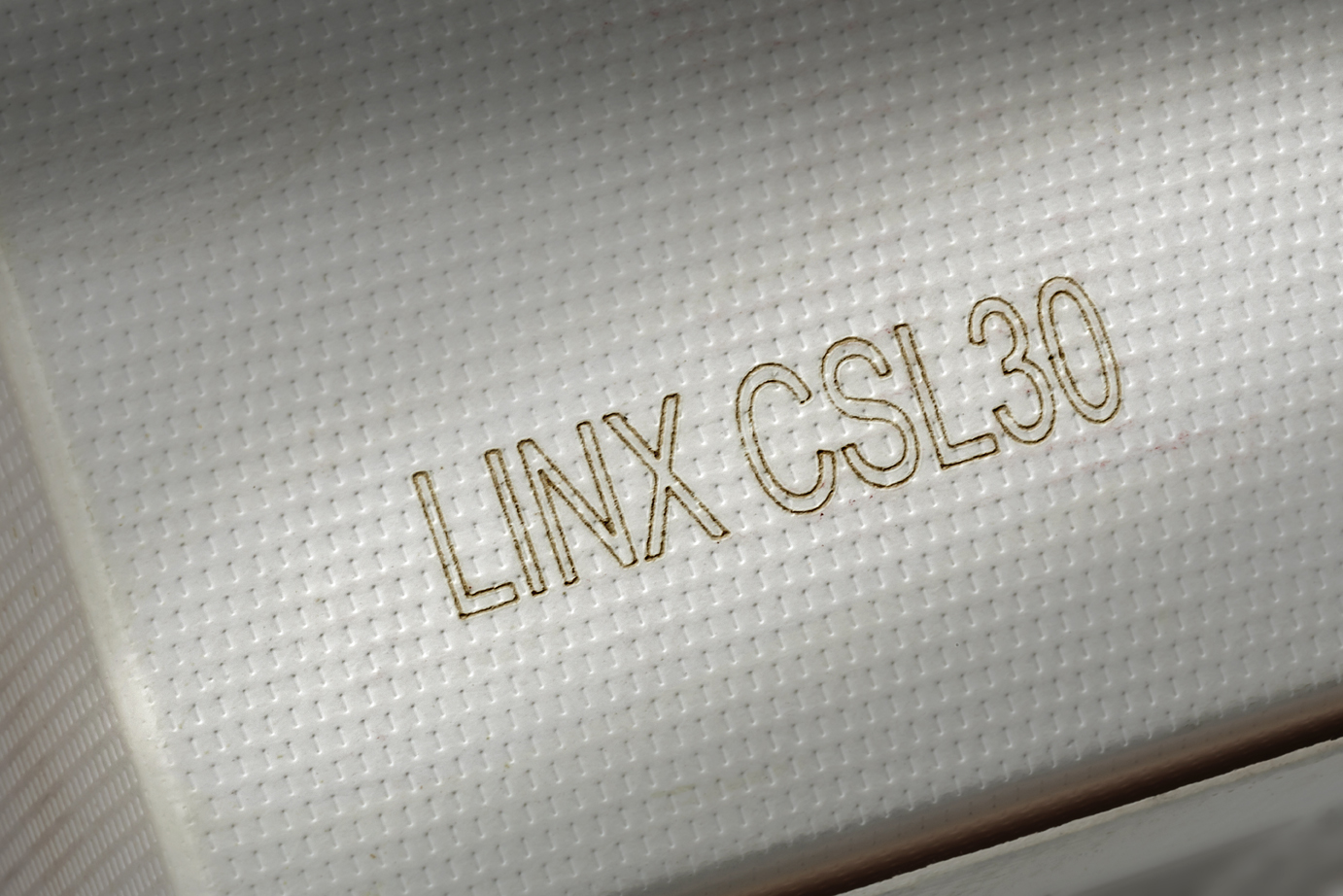

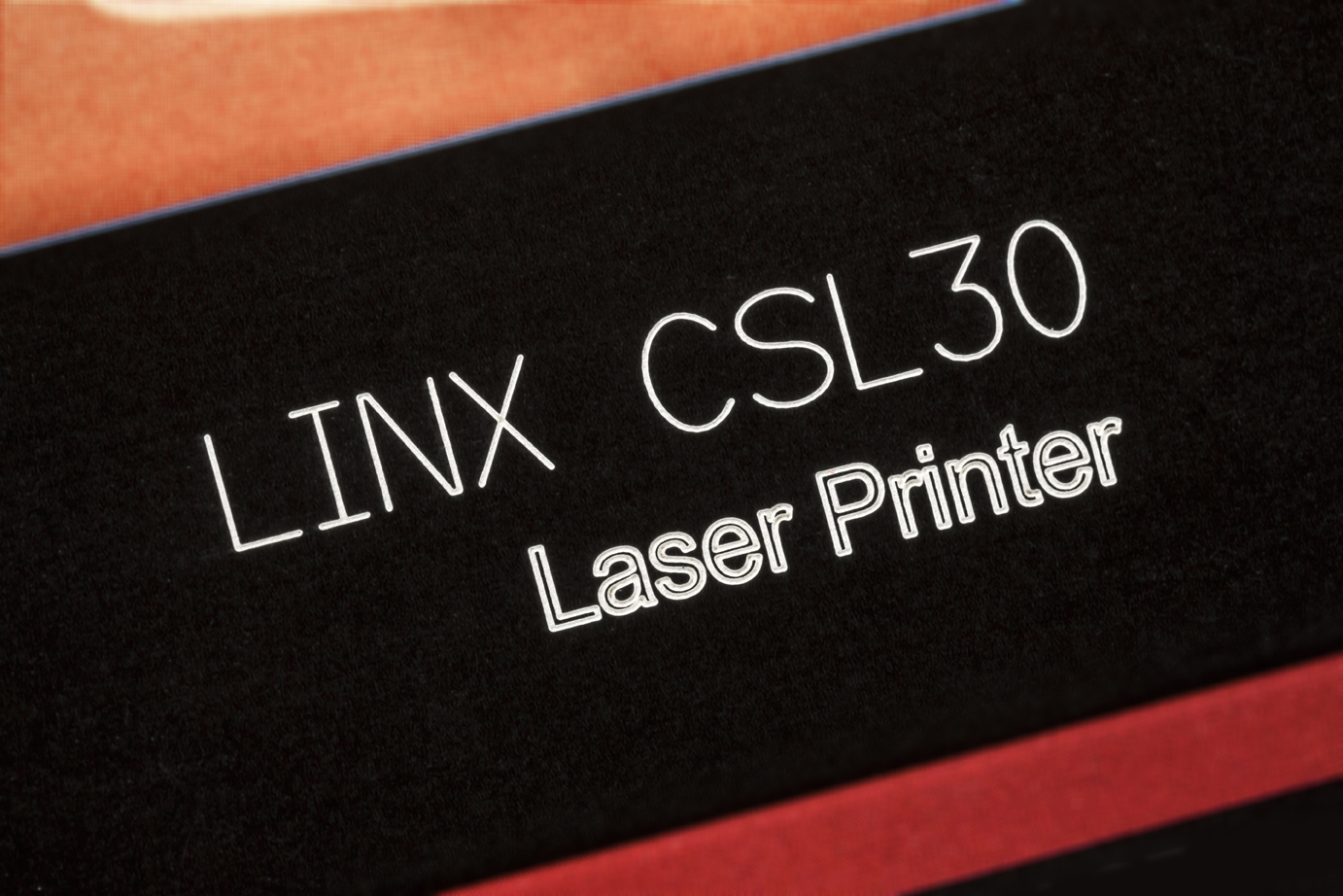

The Linx CSL30 laser coder produces sharp codes on fast lines, and even on hard to mark materials such as glass and rubber. It’s been designed to keep up with your coding requirements as they change – line speed, code complexity, or material types – with no additional investment needed.

Key benefits

Easy to use

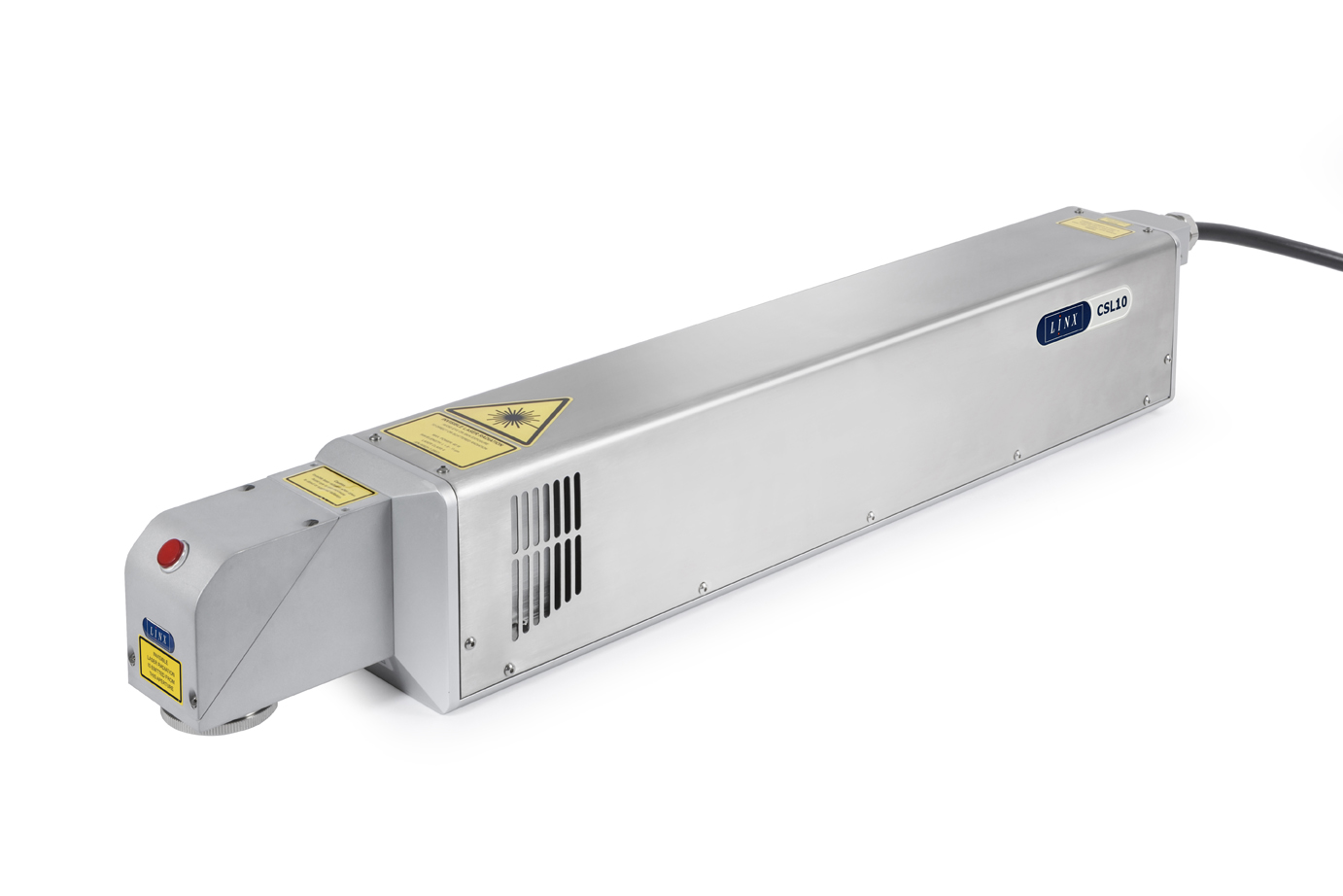

- Easy line integration – detachable marking head with quick disconnect cables

- Multiple beam delivery options allow for coding in any orientation

- Easy message creation and management of printing parameters with the large colour LinxVision® Touch Screen, and LinxVision software

- Reduce your coding errors and meet coding regulations with password controls that can restrict access to qualified personnel only

Meet production targets

- Reduce running costs and delays with 45,000* hour tube life – one of the longest on the market

- Service intervals typically twice that of the industry standard

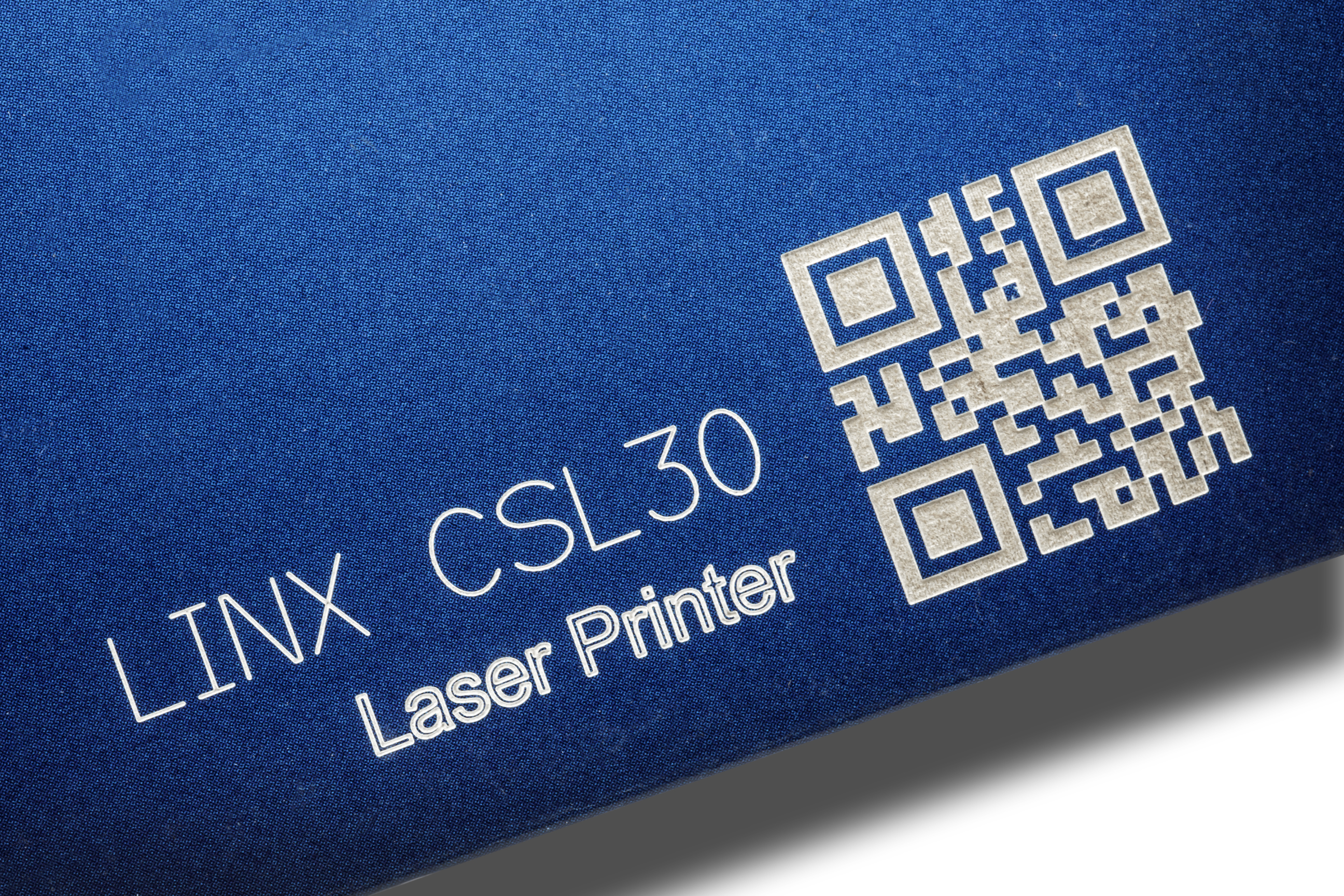

- A powerful, four-core processor allows printing of complex messages – including 2d barcodes, QR codes and logos – on fast lines with no compromise on code quality

- No expensive factory air for cooling

Print in more applications

- Crisp, clear coding on glass, even at high line speeds, with VisiCode®, a unique set of parameters

- Flip, mirror or curve text – easily code onto difficult shapes

- Over 20,000 different configurations to economically meet your coding requirements

- Wide web applications for large area coding or multiple lines of products

*tube life is application dependent

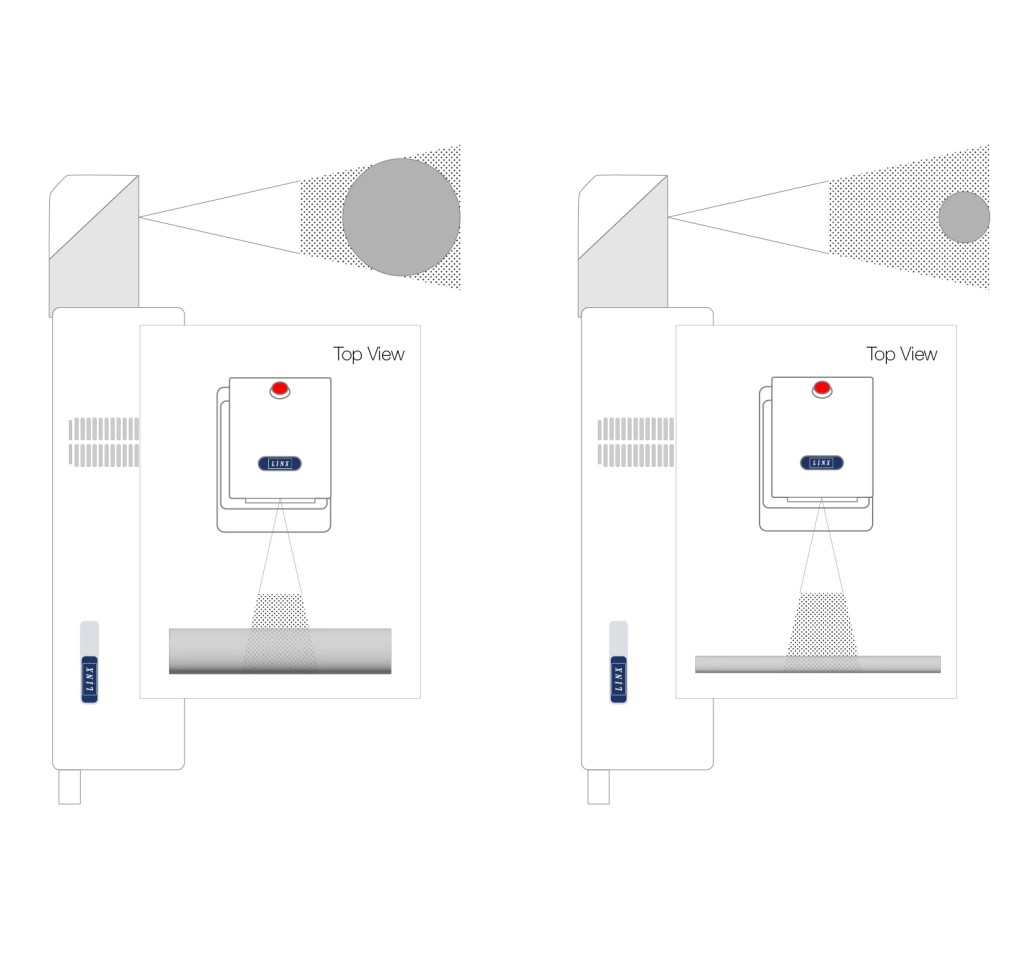

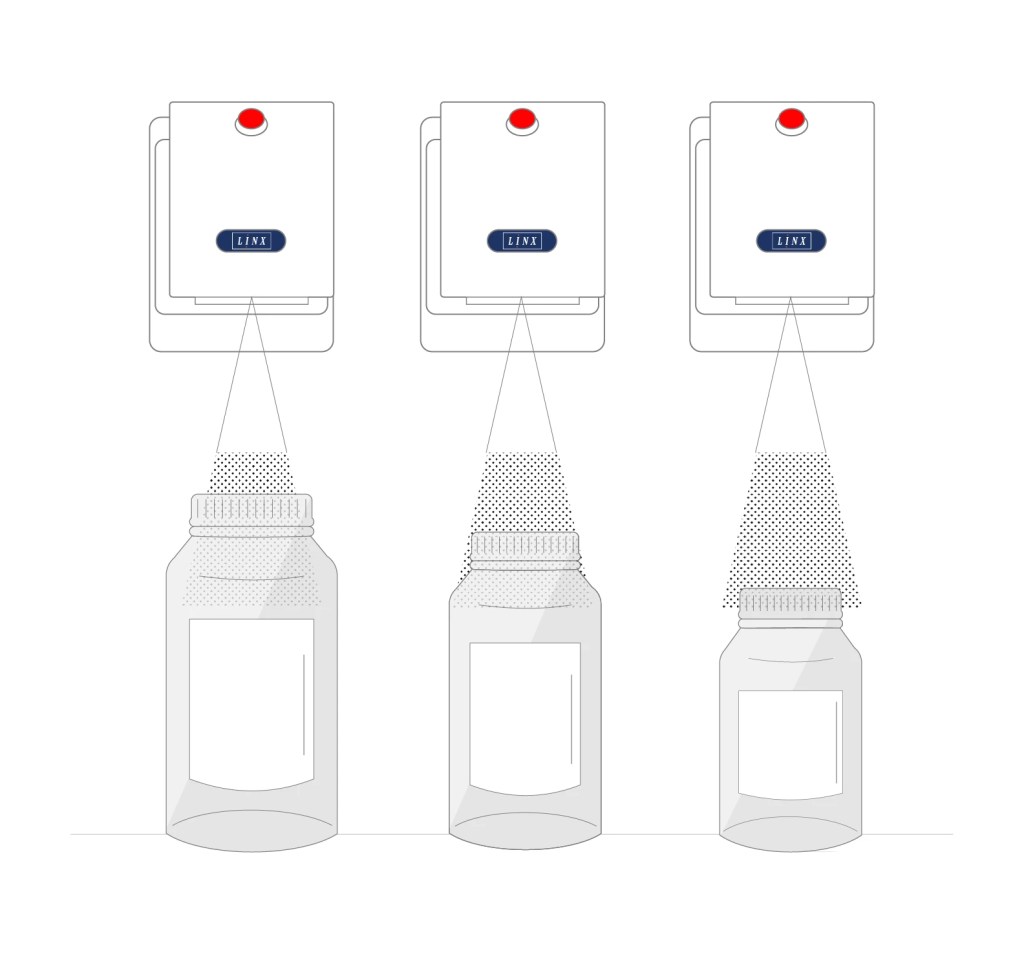

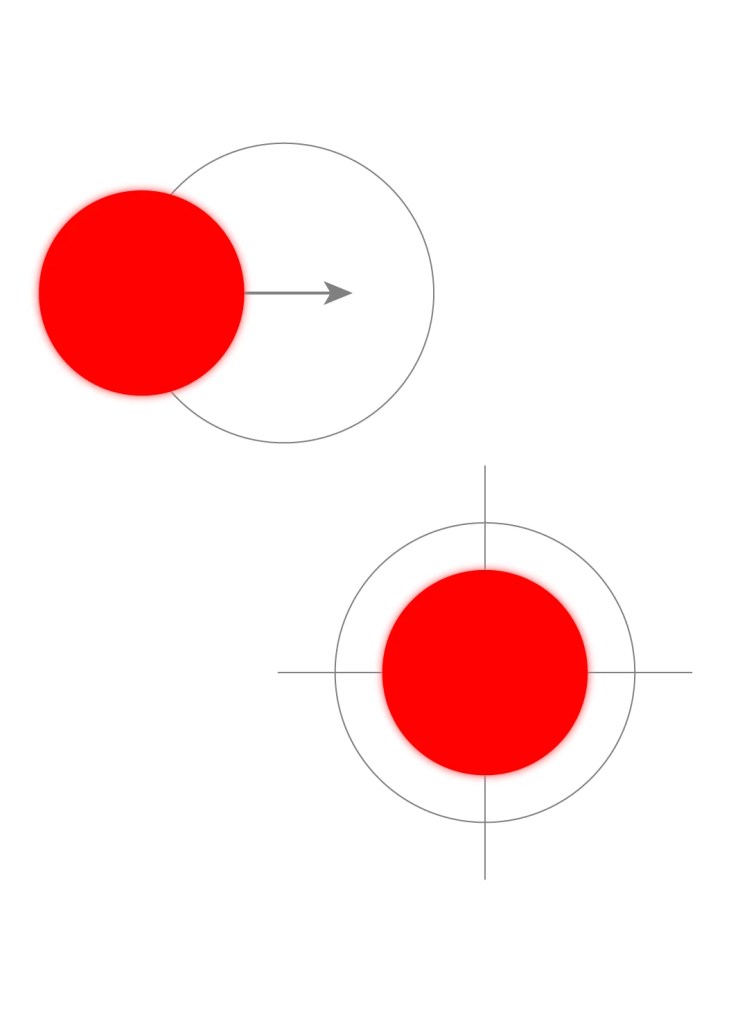

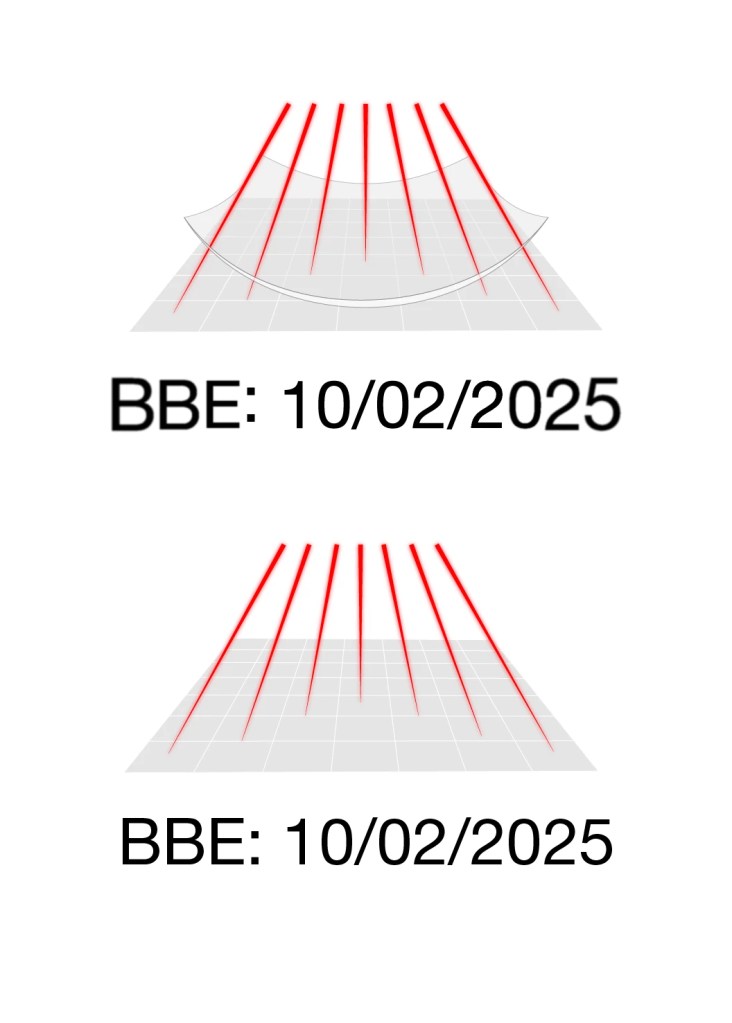

Simplified focus technology

The adjustable focus laser marking head with integrated simplified focus technology has been designed for lines with frequent product changeovers. The simplified focus technology allows the laser to quickly adjust the laser working distance and focus, meaning there is no need to move the laser or adjust it for different height or width products. You can mark various sized products without laser adjustment, reducing changeover time and eliminating errors.

Simplified focus technology

Built-in pilot laser

Ensures products are marked in the right place.

Built-in focus finder

Simplifies the marking distance setting accuracy.

Flat field correction

Constant code quality across the whole marking area.

Optional WiFi access box

Optional WiFi access box provides WiFi connectivity where standard wired connections are not available.

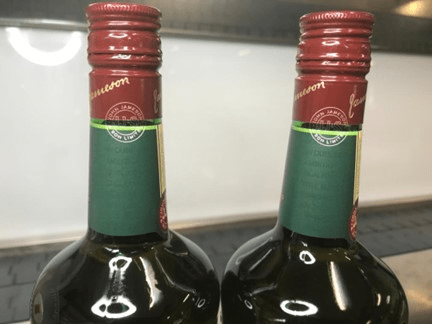

Case Study

Irish Distillers, Ireland’s leading supplier of spirits and wines and producer of some of the world’s most well-known and successful Irish whiskeys, are using Linx CSL30 and CSL60 lasers to ensure brand identity and anti-counterfeiting of their Jameson whiskey.

Only original Jameson whiskey bottles have their bottle distinctively marked with stamp of approval that goes over the seal, glass and label perfectly aligned, highly visible and permanent.

Resources

CSL30 Datasheet

Linx CSL30 coding onto card boxes

VisiCode Datasheet

LinxVision Datasheet

Irish Distillers

Technical Specifications

Coding and marking capability

- CO2 scribing laser coder

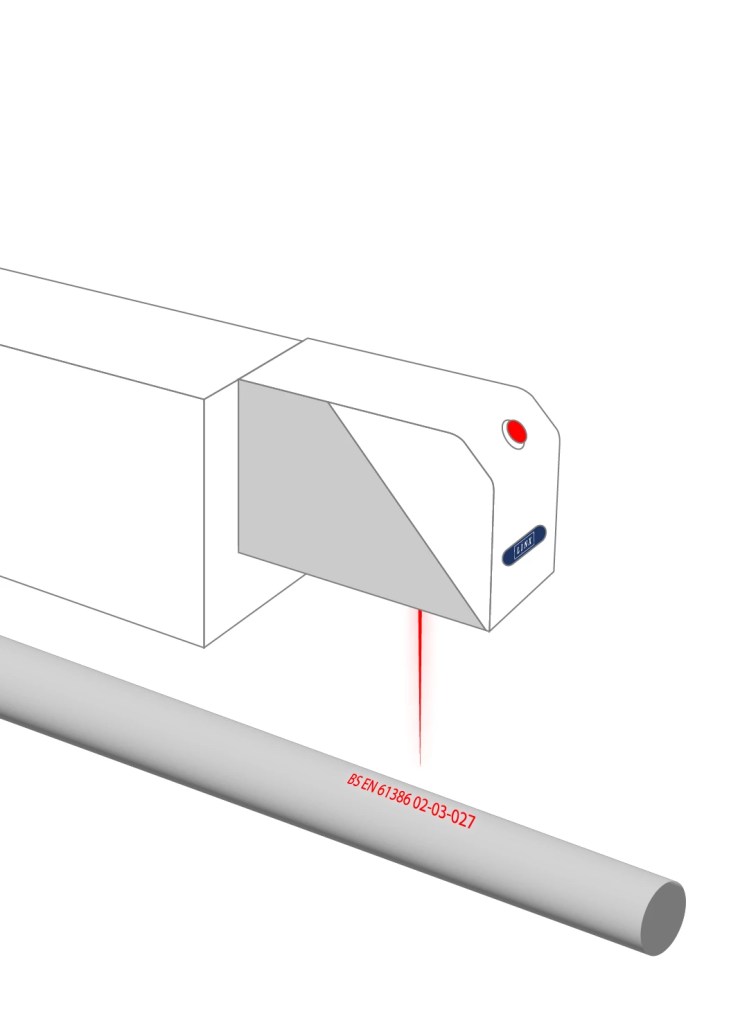

- Line speed – up to 900 m/min (code and substrate dependent)

- Maximum laser output power at lens – 30 W

- Lens and head options (range):

- Spot Size 0.12 mm – 1.6 mm

- Marking Field 29 mm x 36 mm to 440 mm x 601 mm (wide web application)

- Mark distance 67 mm – 576 mm

- Number of lines of text – only limited by character size and marking field size

- Character height – up to marking field size

- Print rotation – 0-360°

- Marking head rotation – 0-360°

- Code options: date, time, static text, variable text, serial numbers, alphanumeric, shift codes, increment/decrement (batch count), ID Matrix 2D codes, barcodes, QR codes, graphics and logos, Julian dates, custom date and time formats

- Laser tube wavelengths – 10.6 µm, 9.3 µm, or 10.2 µm

- Marking head options – 4 marking heads available as standard

- Versatile Beam delivery options for easy integration into your production line:

- Down (90°) or Straight (0°) Shooter

- 360° Beam Extension Unit (BEU)

- Variable length Beam Turning Unit (BTU)

- IP rating – IP54 as standard, IP65 option

- Air cooled – not factory air

- Large volume gas tube can last in excess of 45,000* hours

- Laser tube warranty – 2 years

- *Tube life may vary according to application.