Linx Printhead

Linx unique CIJ printheads are designed to be robust and clean, saving you valuable time and money.

Spend less time cleaning your printhead and more time keeping your production running with the Linx unique AutoFlush printhead system.

The Linx CIJ printhead automatically cleans itself daily, so you don’t have to. Uniquely designed with AutoFlush technology, the Linx printhead has a typical cleaning interval of up to three months, providing increased production efficiency and savings on valuable cleaning time and fluids. Other printers need more printhead cleaning; some daily.

Key benefits to your line

Robust

No daily adjustments: Linx printheads are purposely sealed, protecting critical components from damage.

- Minimal risk to your production line. No daily interaction and interventions means the risk of associated issues is minimised

- Critical components are protected from knocks due to the robust sealed design

- No adjustments needed, no fragile or moving parts

- No need to replace parts, no screws or parts to move

- Risk of damage to exposed components is eliminated. Other printheads can be fragile and need repairs, Linx’s is robust.

Clean

No regular manual cleaning: Linx printheads save you valuable time. Less physical cleaning means more time to be productive elsewhere.

- Minimal manual cleaning. AutoFlush technology automatically cleans the printhead for you

- Less physical cleaning means more time to be productive in the important areas elsewhere

- Less impact on the environment. Less cleaning means less fluid materials used, meaning less impact on the environment.

- Reduced chemical contact and odour. Less cleaning means fewer open bottles and cleaning materials, making it safer for you and your staff.

Reducing the need for manual cleaning typically to as little as four times a year.

Why the Linx printhead is unique

Intelligent printhead system

The Linx printhead automatically adjusts to changing environmental conditions, giving consistent print quality from start to finish. The temperature and jet speed is measured in the head, in real-time, allowing the system to automatically make instantaneous adjustments to keep the print quality clear and consistent.

Other printers don’t measure jet speed in the head and therefore can’t react so quickly. Viscosity in other printers is often measured in the printer not in the printhead, meaning adjustment is slower, resulting in poor and variable print.

Linx AutoFlush Process

AutoFlush automatic cleaning system automatically cleans the printhead on startup and shutdown, meaning less interaction. At each startup and shutdown the printer runs a unique AutoFlush routine to clean the printhead from the inside, producing zero solvent waste.

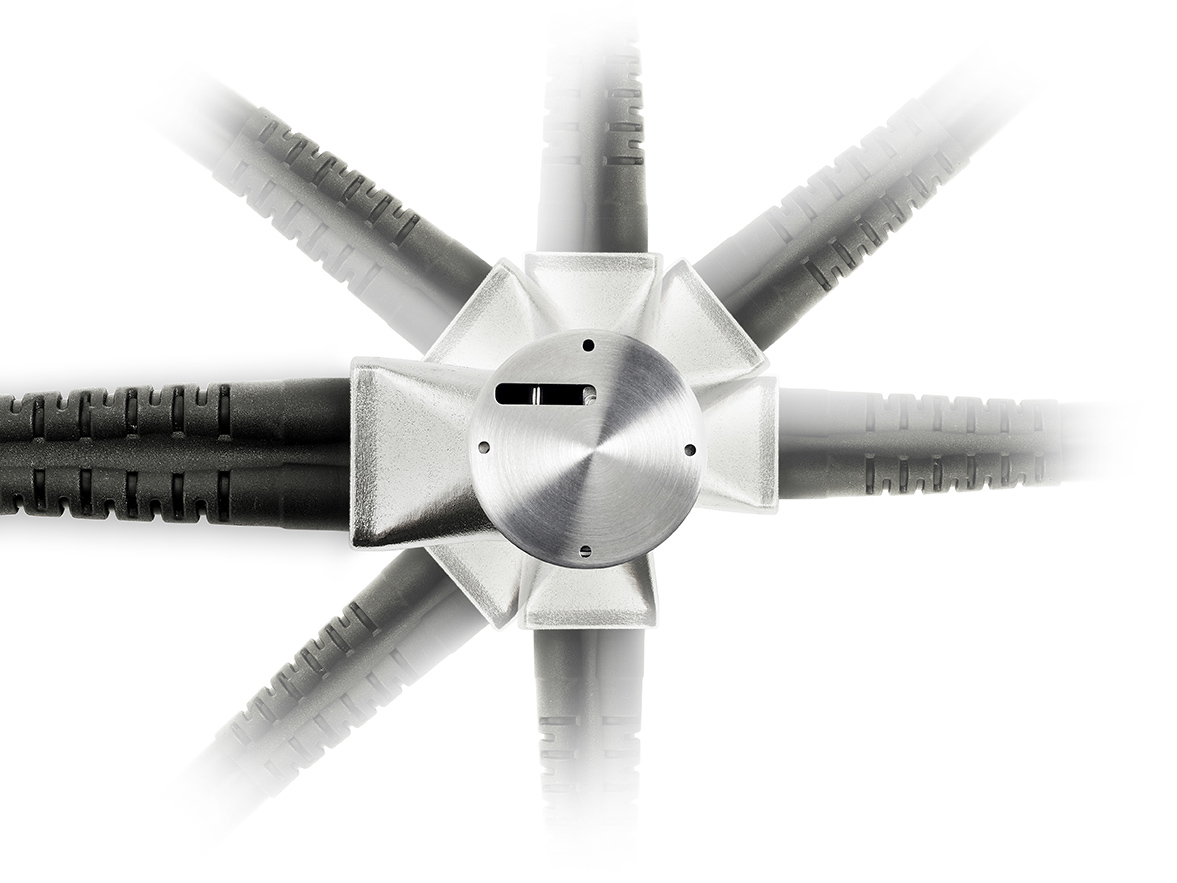

Robust Printhead

Hermetically sealed so that all the critical components are built and then sealed, providing protection from liquids, knocks and the manufacturing environment. The method we use to seal the printhead reduces downtime as it makes high voltage tracking (EHT trips) in the head less frequent.

Resources

Linx AutoFlush Process

Diagram

Linx Automatic Printhead Cleaning

Explainer Video

Linx AutoFlush Process

Technical Video

Further innovative printhead technology features

Unique curved plate

- The plates in the printhead have been specifically designed curved and not angular, reducing the concentration of charge and the likelihood of ink build up and EHT trips

- Curved surfaces means the printhead runs for longer, minimising the risk of ink build up on the surfaces where the charge is concentrated, and minimising downtime

Printhead options

- Midi – 62 micron nozzle for legible characters that meet everyday traceability requirements

- Midi Plus – larger nozzle where bolder print is required and for higher performance with pigmented inks

- Right-angled variant – to fit into tighter spaces

- Micro – for very small print (Linx 7900 Series)

- Mini – for higher speed printing (Linx 7900 Series)

Flexible conduit

- Hydrogen peroxide resistant conduit option

- Conduit designed with two pipes instead of one, for additional flexibility

- Range of conduit lengths available

Capability

- Print speeds up to 10 m/s

- Prints up to 6 lines

Related products

Specialist Coding

White ink marking for dark or coloured substrates

Linx PrinterNet

See the real-time status of your

Linx printers, anytime, anywhere