Fibre Laser Coders: FSL20 & FSL50

Fibre laser technology for permanent coding on a wide range of materials

Permanently mark on a wide range of materials, including metal, rubber, plastic, and packaging foils.

Very fine spot size creates excellent quality codes and makes Linx Fibre lasers ideal for marking very small components, or large amounts of information onto small areas.

Text, machine readable codes, graphics and logos are all marked with extreme clarity for traceability; ideal for pharmaceutical, medical devices, automotive and electronics industries, as well as FMCG packaging.

Key benefits

- Laser tube life of over 100,000 hours – less downtime

- Fine spot size for high quality codes

- Two beam orientation options allows coding in any direction

- Choice of 4 lenses for codes tailored to your requirements

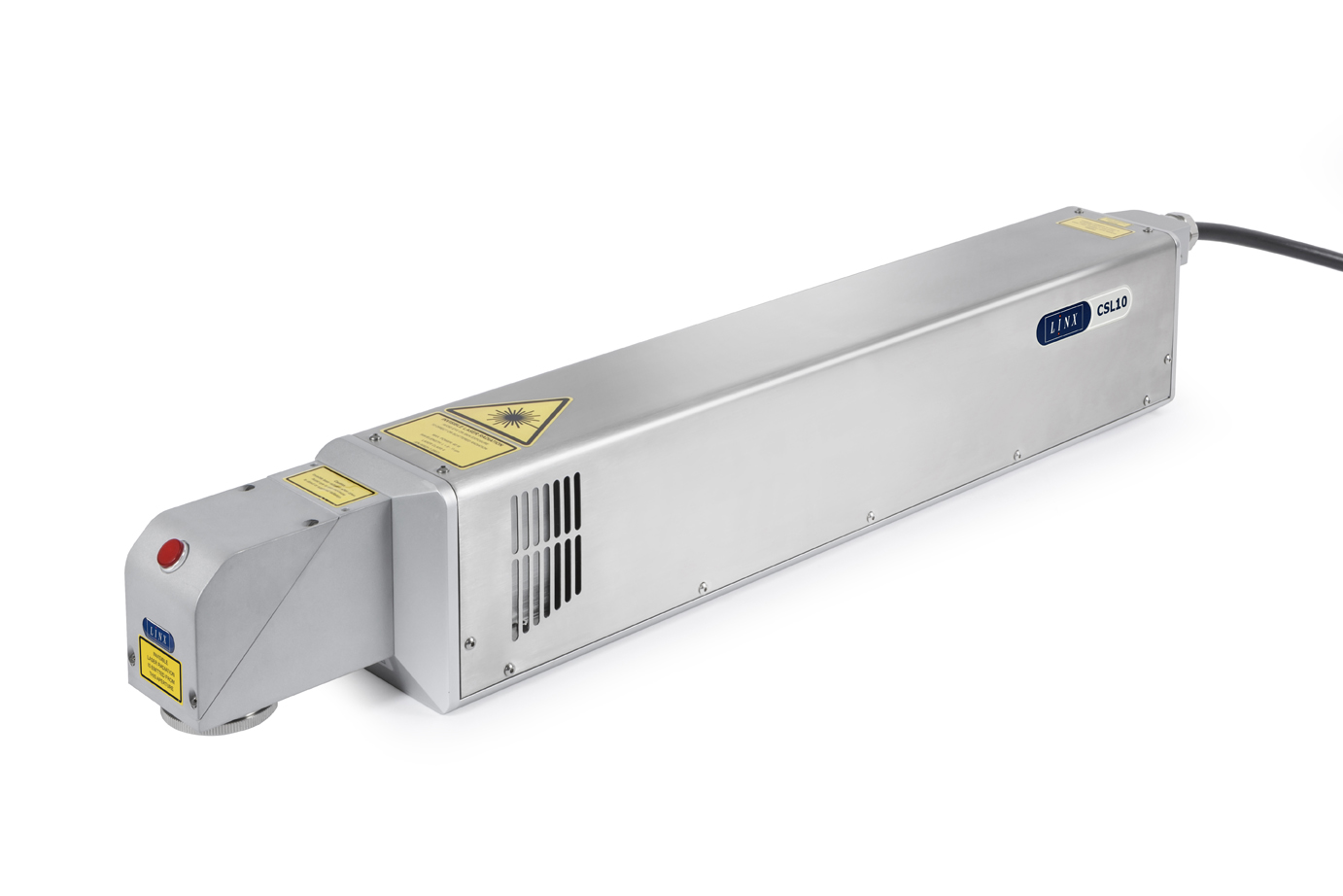

- Compact marking head for easy integration into moving and static lines

- Internal air cooling system for increased efficiency and less maintenance

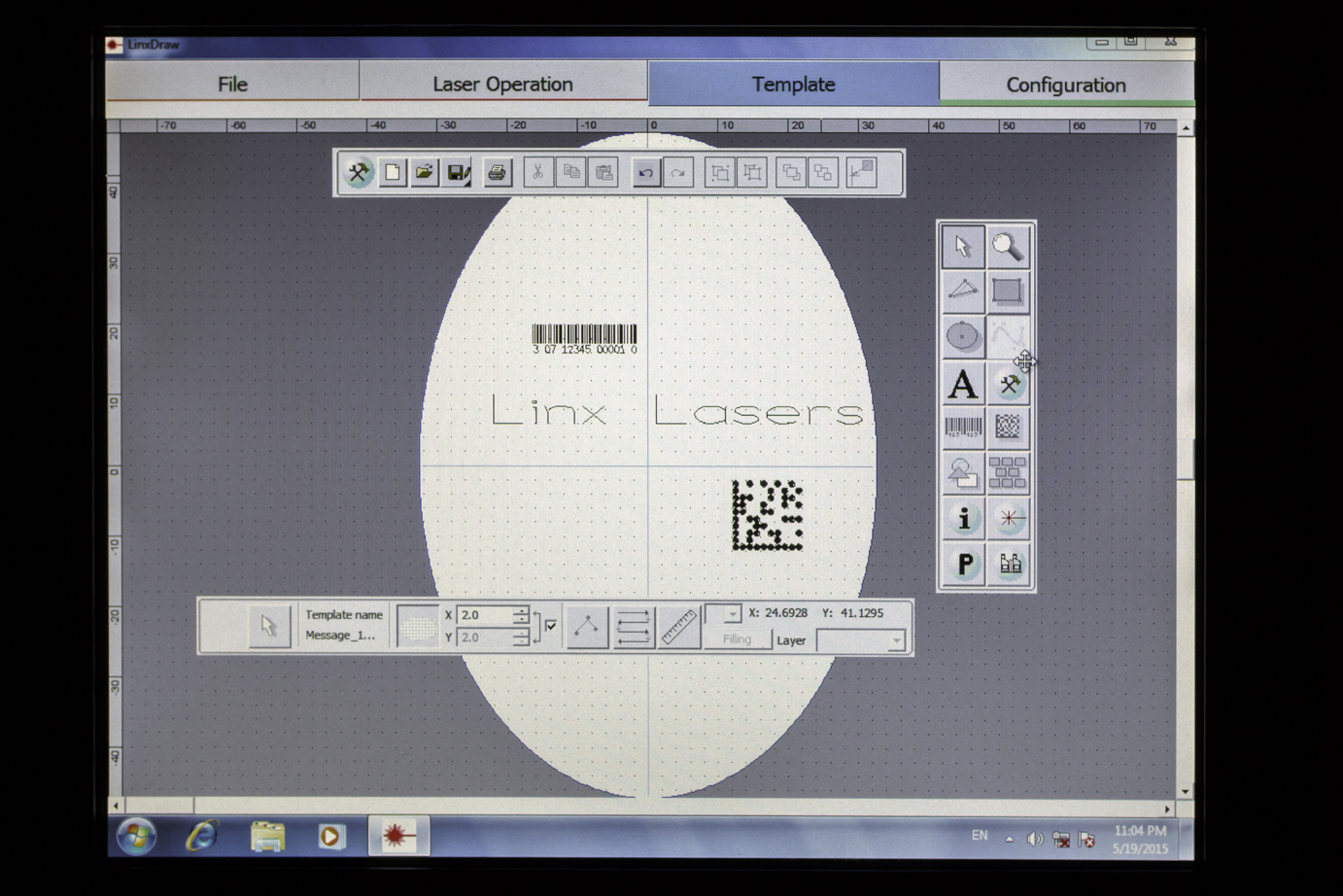

- Quick message creation reduces time spent on setup and changeovers

- Extremely efficient use of the laser with no compromise on code quality or speed

Resources

FSL20 FSL50 Datasheet

Laser Coding Solutions Brochure

Laser Marking Technologies

How Linx Laser Solution Can Help Your Business

Technical Specifications

Marking Formats

- Standard fonts (Windows® TrueType®/TTF; PostScript®/PFA, PFB; OpenType®/OTF) ·

- Individual fonts such as high-speed or OCR ·

- Machine-readable codes: Bar codes: BC25,BC25I, BC39, BC93, EAN 8, EAN 13, BC128, EAN 128,Postnet, SCC14, UPC_A, UPC_E, RSS14TR, RSS14ST, RSS14STO, RSSLIM, RSSEXP Data matrix 2D codes: ECCOOO, ECC050, ECC080, ECC100, ECC140, ECC200, ECC PLAIN, QR ·

- Graphics/graphic components, logos, symbols, etc. (the most common file formats such as DXF, JPG,AI can be imported) ·

- Linear, circular, angular text marking; rotation, reflection, expansion, compression of marking contents ·

- Sequence & serial numbering; automatic date, layer, time coding, real-time clock; online coding of individual data (weight, contents, etc.)

Performance

- Line speed – 1 to 6,000 mm/s (typical). ·

- No of lines of text – Only limited by character size and marking field ·

- Character height – Up to marking field ·

- Print rotation – 0- 360 degrees ·

- Operation mode – pulsed (Q switch)

Physical Characteristics

- Material – Painted sheet metal housing ·

- Weight: marking unit/supply unit – 8kg / 19kg ·

- Laser head – IP54 ·

- Conduit length – 2.7m ·

- Minimum bend radius of conduit – 90 mm ·

- Head mounting options – 90-degree (standard) and straight-out (option) ·

- Cooling system – Air cooled with automatic overheat detection ·

- Supply voltage / frequency – Auto selection range 100 to 240 V / 50/60 Hz (auto range) ·

- Maximum power consumption – 500 VA ·

- Operating temperature range -10 – 40° C ambient ·

- Humidity range – 10% to 90% relative humidity, non-condensing

Communication

- Ethernet, TCP/IP and RS232, digital I/Os ·

- Inputs for encoders and product detector triggers ·

- I/Os for start, stop, external error, job select, trigger, trigger enable, encoder, system ready, ready to mark, marking, shutter closed, error, bad, good signals and machine/ operator interlocks