Why use Linx Laser Coders and Marking Machines?

Linx laser marking machines and laser coders are ideal for high print volumes – such as food, beverage and pharmaceutical products. Linx industrial laser printers also provide permanent traceability, making them ideal for laser part marking in automotive and aviation manufacturing.

Linx laser marking systems offer any-orientation coding alongside full touch-screen control, low running costs with minimal maintenance and zero consumables – providing an affordable and effective solution compared to other marking technologies.

Why Choose Linx Lasers

Laser coding and marking is a permanent and accurate way of applying code onto your products. Find out why Linx lasers are ideal solution for your permanent coding and marking needs.

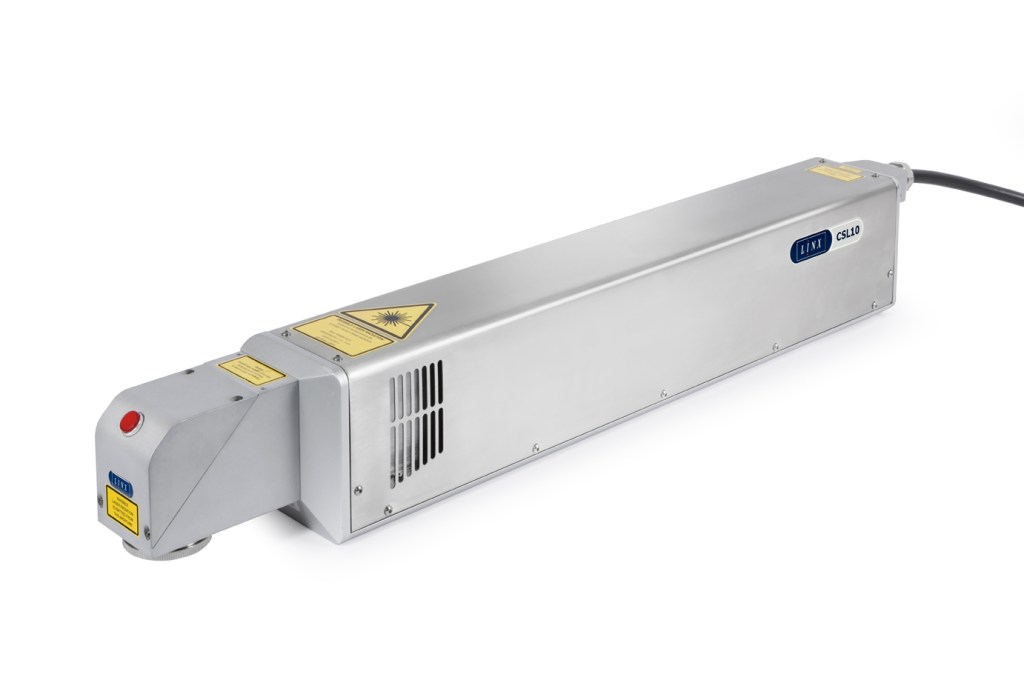

Linx CSL10

10W – Economical yet versatile, with easy installation

Applications & Materials

Broad materials support incl. Glass | Barcodes | Batch coding | Data Matrix & QR codes | Up to 900 m/min | Print unlimited lines of text

Key Benefits:

- Handles variety of simple to complex code types

- Easy setup, with touchscreen message management

- Laser tube lifespan estimated at 45k hours

CASE STUDY: Linx CSL10 enhances quality assurance for NCI Packaging

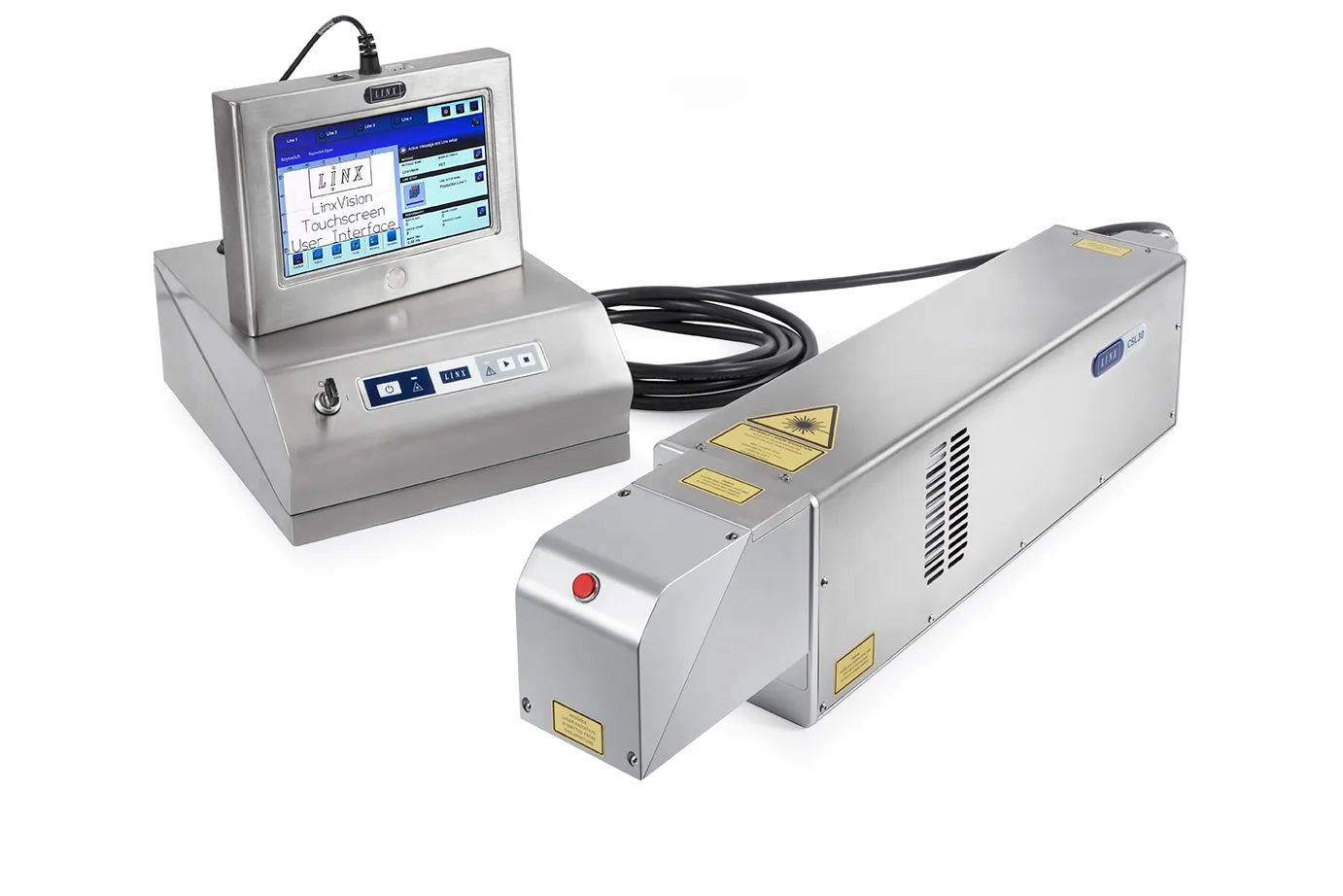

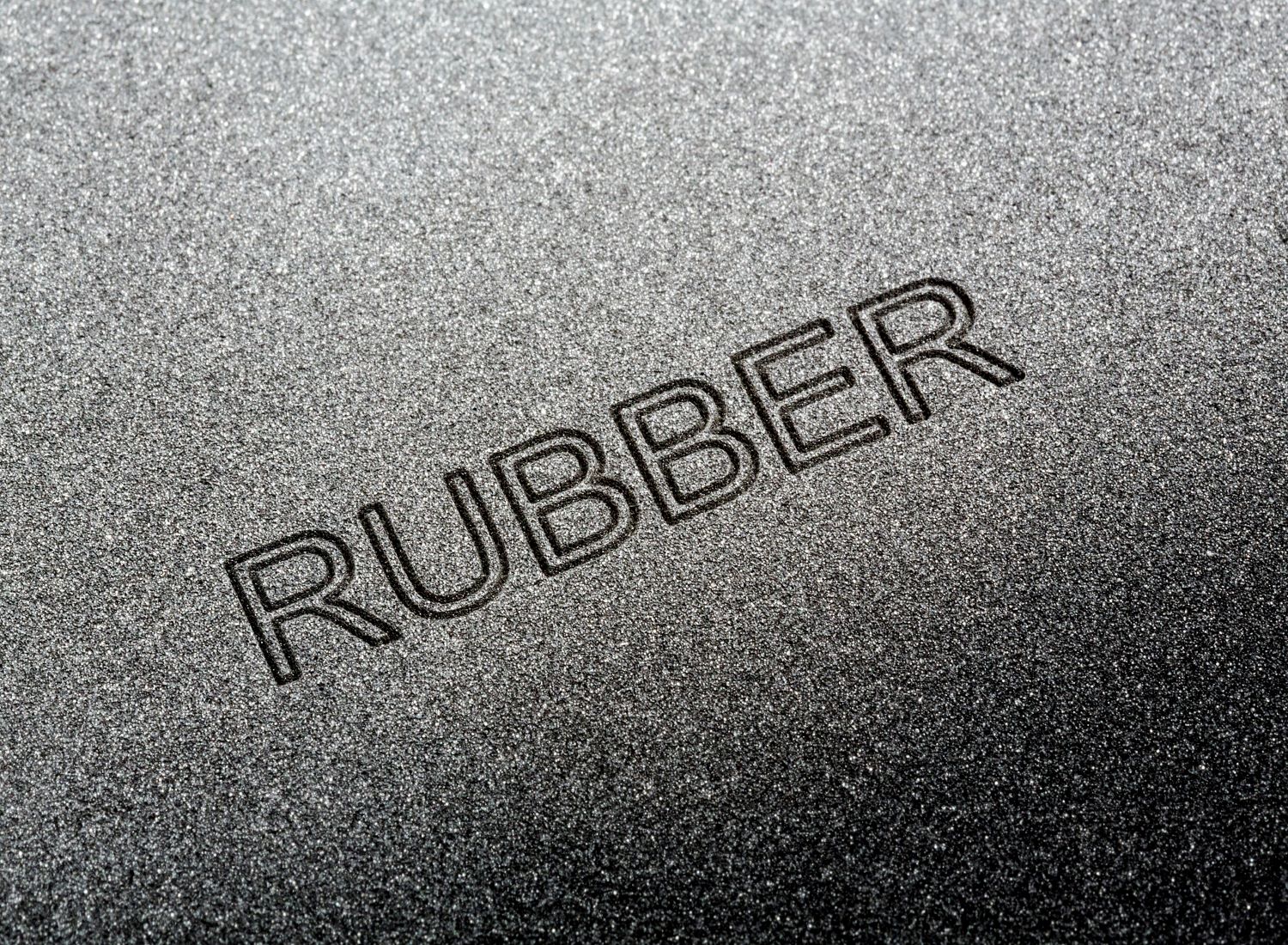

Linx CSL30

30W – For high-speed marking of complex codes

Applications & Materials

Variety of materials incl. Glass, Rubber | Barcodes | Batch coding | Data Matrix, QR and dot codes | Up to 900 m/min | Print unlimited lines of text

Key Benefits:

- Flexible solution, configurable to coding requirements

- Quick to deploy and transfer to new lines

- Multiple beams allow for coding at any orientation

CASE STUDY: Linx CSL30s provide clear quality codes for Bruichladdich Distillery Co.

Linx CSL60

60W – Flexible solution for high-speed retail coding

Applications & Materials

Materials support incl. Glass, Rubber | For harsh environments | Barcodes | Batch coding | Data Matrix & QR codes | Up to 900m/min | Print unlimited lines of text

Key Benefits:

- Ideal for beverage, automotive industries & more

- Over 20,000 configurations to meet code requirements

- Code up to 70,000 bottles per hour

Linx FSL20 and FSL50

20W/50W – Quality codes for fine print & small components

Applications & Materials

Wide materials support: metal, rubber, plastic, foil | Barcodes | Data Matrix & QR codes | Up to 6,000 mm/s | Print unlimited lines of text

Key Benefits:

- Finer spot size creates higher-quality codes

- Ideal for large volume and small area coding

- Well-suited to medical, automotive and electronics sectors

Linx SLHP

120W – The fastest speeds, with no compromise on quality

Applications & Materials

Range of material marking: glass, plastic, rubber, labels | Harsh environments | Barcodes | Data Matrix codes

Key Benefits:

- Equipped with large area marking functionality

- No need for consumables, reducing ongoing costs

- Fast, complex coding for medical, automotive, alcohol/tobacco industries & more

A concentrated beam of light is deflected by mirrors through a lens to form characters. Laser coding is achieved by removing material or a coating from the product or packaging, or by changing the surface of the substrate. In each case, the code is permanent.

The difference is simple. Laser marking is the placement of the information on the surface with little to no penetration. Engraving refers to placing the information with much more force to reach under the surface of the material.

A laser coder is a non-contact option for permanent clear quality marking. It requires minimal maintenance and zero consumables. This technology is an ideal alternative where a continuous inkjet (CIJ) machine is not feasible.

We have a range of Lasers to offer suited for various application types. To get a better and closer quote please get in contact with us here via web form or phone call. We will be happy to help.