Aviation and Aerospace Part Marking and Coding

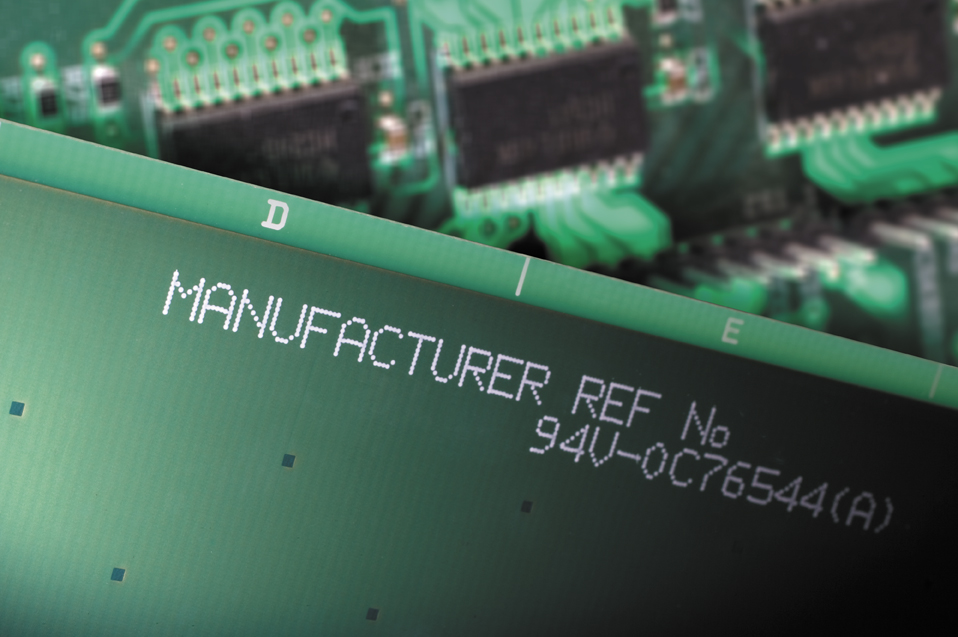

Within the aviation and aerospace industry, it is vital that accurate information is permanently applied for traceability. Safety-relevant information is printed on these components by using a barcode or matrix code containing specific encrypted data. Such marking requirements on the production process can be a challenge with customer specifications, high-speed lines and tight production deadlines. However, Linx provides flexible, cost-effective solutions that deliver high quality, and clear traceability across a variety of different pack formats and material types to help meet our customer’s needs.

What parts can I code?

Linx offers a solution for all parts of an aircraft, from a large wing to the smallest screw coding unique part numbers, serial, and data matrix codes.

- Fasteners: Nuts, bolts, screws, rivets etc. We have machines coding as small as 0.1mm high

- Systems Components: engines, pumps, moving shafts, flight control parts etc. We offer specialised inks able to penetrate grease and oil surfaces, allowing permanent marking

- Airframe Parts: Landing gear, brake disks, structural components etc. A wide range of inks are available in different colours showing up on light and dark surfaces

- Cabins: seats, control panels etc.

Printer Types for Aerospace and Aviation Industries

Continuous Inkjet (CIJ) Printers

Our Continuous Inkjet and Laser coders can help maximise uptime between multiple SKU’s with quick, error-free code changeovers while line setups can be stored and retrieved for repeat work.

Linx CIJ printers are designed to be durable and full-featured, meeting the highest standards of coding quality.

- Reliable coding and marking in extreme manufacturing conditions

- IP rated to cope with wet and dusty conditions

- Range of inks for specialist marking, e.g., invisible/UV coding

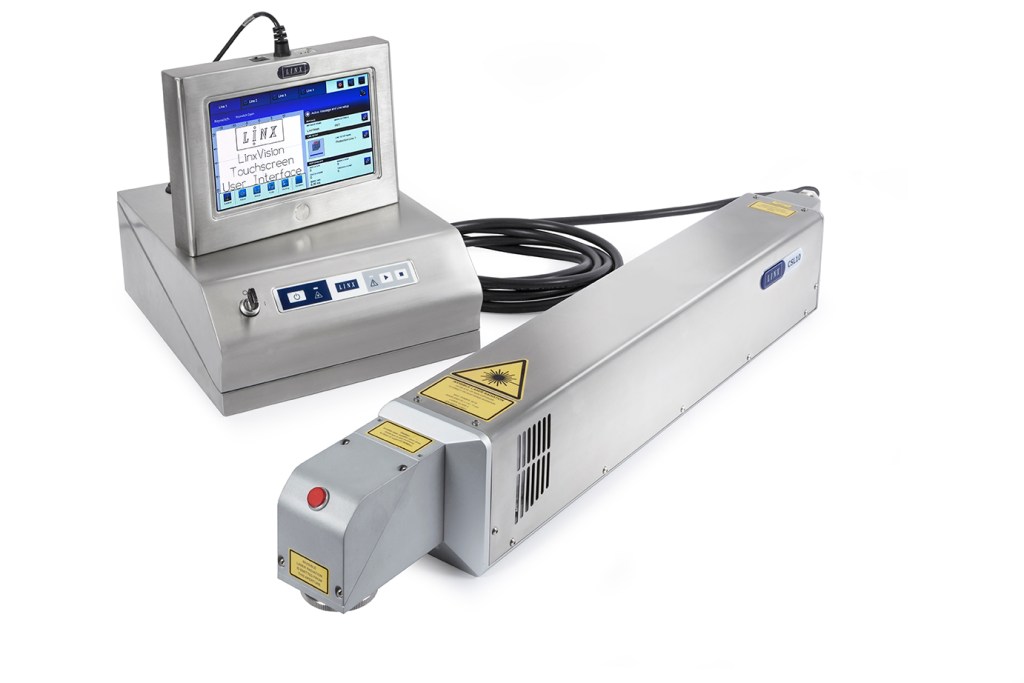

Laser Printers

Linx laser metal marking machines and coding systems provides permanent traceability, making it ideal for steel part marking in automotive and aviation manufacturing.

- Improves productivity

- Optional IP protection for harsh environments

- Able to print very small characters 0.1mm high characters

Contact Us

Why not get in touch with one of our sales reps to talk about how Linx can support your coding and marking needs?

Resources

Beavertown Brewery Case Study

LMA Services Case Study

Linx Contrasting Inks Datasheet

Related

Automotive

A modern vehicle contains thousands of individual components, each of which may need a specific part number.

Electronics

Solutions suitable for the complex, and often delicate, manufacture of circuit boards, electronic components, and wires.