High-Speed Wire and Cable Marking Machines

Linx manufactures specialist wire and cable printing machines that are simple to use and minimise total cost of ownership without compromising quality or uptime.

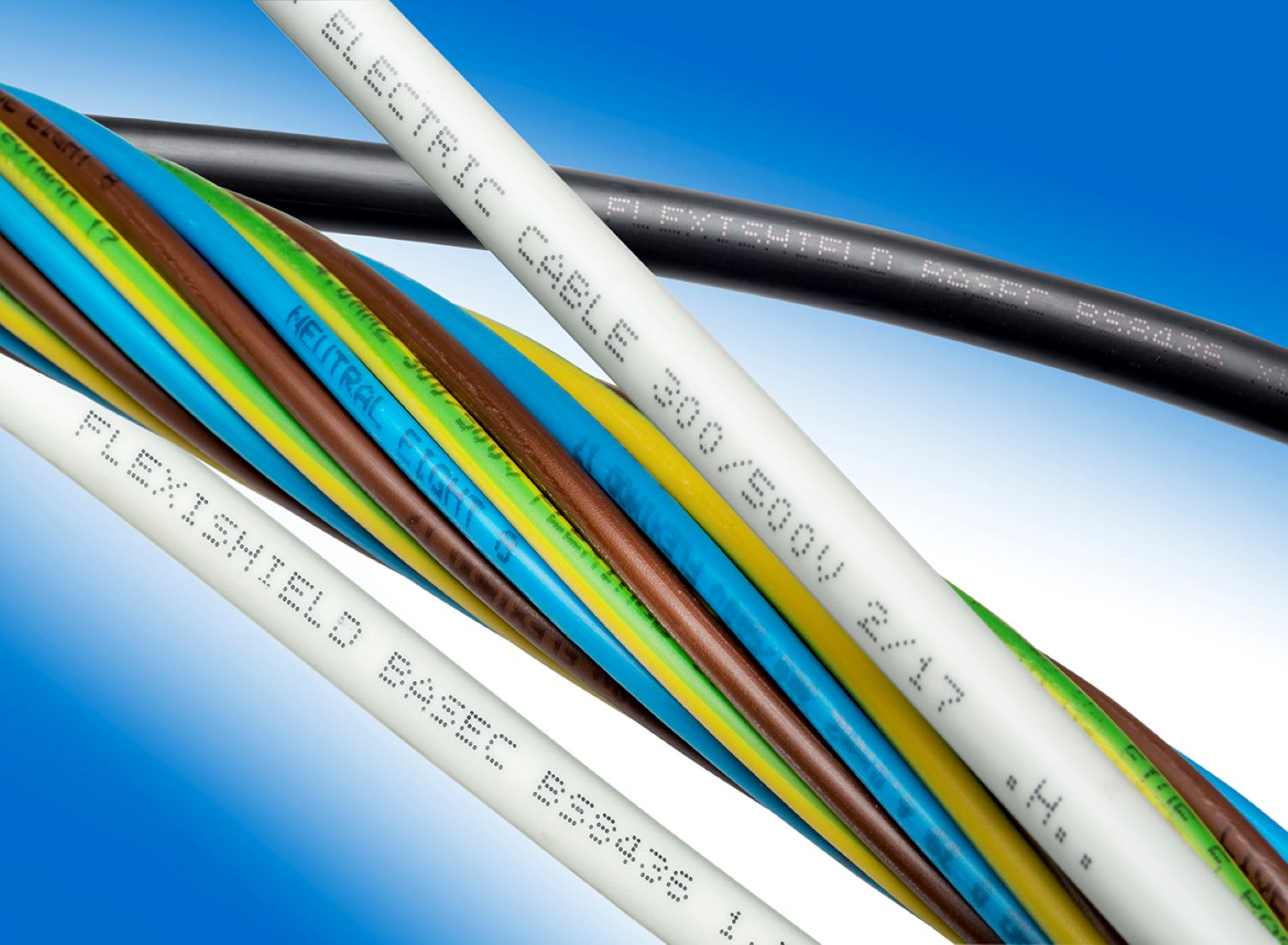

Wire and cable printing requires reliable traceability and product identification across a complex range of product sizes, materials and colours – sometimes in difficult production environments, plus with a range of legislative and customer expectations to meet.

Linx high-speed cable marking machines provide a robust answer to these common requirements. Both continuous inkjet printers and laser coders from Linx are able to print directly on wire and/or cable, designed especially for reduced maintenance, monitoring & downtime while also offering trouble-free integration with your existing production processes.

Importance of cable and wire marking?

Compliance and identification play a crucial part in marking cable and wire. Correctly marking on labels ensures audit compliance and quality assurance, validating investment into a high quality wire printer or cable marker. Many wires must be labelled according to specific standards ensuring safety and interoperability. Each industry will have other specific requirements with the size of the print, font used and specific information that needs to be included.

Benefits of Linx wire and cable marking machines:

- Easy, intuitive message selection to reduce errors and minimise waste

- In-built reliability with IP-rated outer casings & printheads to resist contamination

- Uncompromisingly fast line speeds, in extreme or difficult manufacturing conditions

- High-quality codes with fast-drying inks or laser coding – robust, easy to read, traceable

- Faster changeovers & flexibility, suitable for a vast range of code sizes & materials

- Integration with metre marking software, enabling full control of code placement

Contact Us

Why not get in touch with one of our sales reps to talk about how Linx can support your coding and marking needs?

Solutions for Coding & Marking Wire and Cable

Linx provides multiple solutions enabling direct wire printing and accurate coding of small characters, even onto fibre optic cables. Browse our products & get in touch with us to discuss your coding solution, tailored to your production requirements, helping you to reduce downtime and scrap page costs to deliver a top-quality service for your customers.

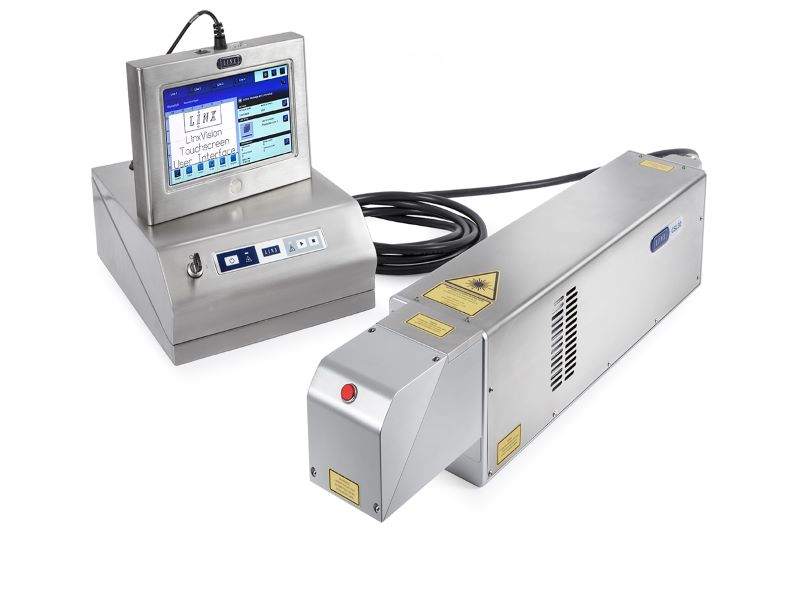

Laser Coders

A permanent marking solution offering high-speed capability for clear and consistent codes, with low downtime and no consumables. Suitable for most materials, with a low cost of ownership over the system’s lifetime.

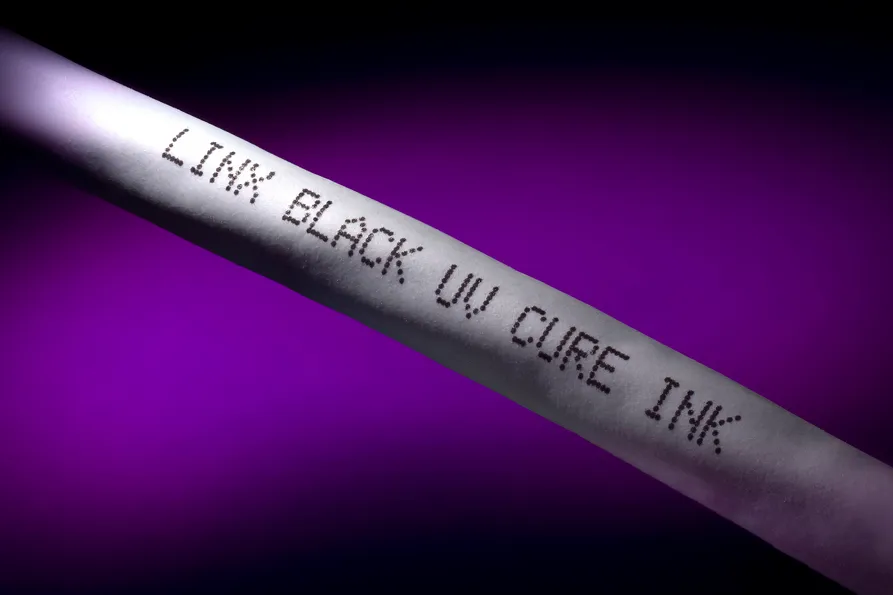

Continuous Inkjet Printers

Linx CIJ solutions provide specialist inks to ensure contrast and durability, printable on most plastics and even fibre optic cables. Flexible & reliable non-contact solution offering speeds of 2,600+ characters per second.

Common Applications & Capabilities

- Traceability

- Product identification

- Characters, text and logos

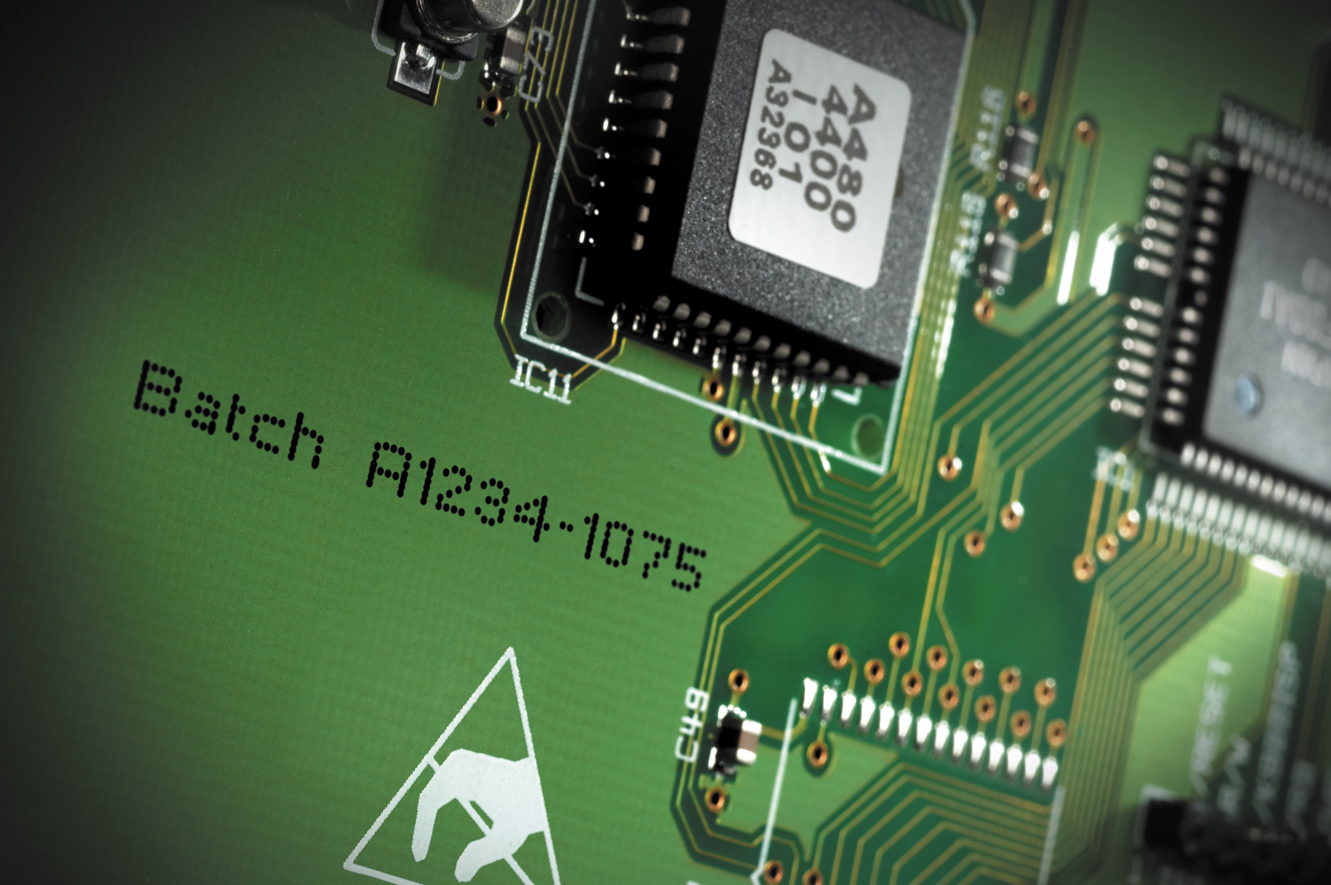

- Batch numbers/lot numbers

- Inks & fluid – pigmented & more

- Wire, cable, fibre optics

- PCBs & electronic components

- Rubber – synthetic & natural

- Plastic – PVC/PE/PVC & more

- Effective with nearly any material

Not sure which product is best for your wire & cable marking requirements?

Related Information

Resources

Choosing The Best Wire & Cable Coding Solution White Paper

Linx Contrasting Inks Datasheet

Special Adherence Inks Datasheet

Parkinson Harness Case Study