The customer need

Wolds Manufacturing Services Ltd based in Lincolnshire is a fragrance manufacturer that constantly invests and develops new ways to support even the most demanding projects in fragrance production. The Company has initially installed Linx SL1 laser marking machine to ensure the permanent traceability coding solution for their customer. Facing issues with counterfeiting of their premium products, Wolds’s customer demanded the best in class marking solution that would solve their problems.

Linx’s laser offering was just the right fit for the job and after initial assessment of requirements and consultation with Wolds, Linx’s Sales Team created a bespoke proposal, taking into consideration factory fit out, production line position and workers safety. Linx’s bespoke solution enabled Wolds to not only address their customer needs, but also ensure the safety of the laser installation and staff operation.

Marking fragrance bottles of various shapes and sizes with batch numbers, codes and origin information using Linx’s lasers allowed Wolds to not only achieve a permanent coding solution of highest quality, but also speed up their production process and save money.

Customer satisfaction and product quality is the most important outcome for us. Linx lasers reliability and the high quality of marking help us to ensure our KPIs are met. The ROI of the coder itself is very high, it has practically paid for itself in less than a year”.

Wayne Baker, Managing Director.

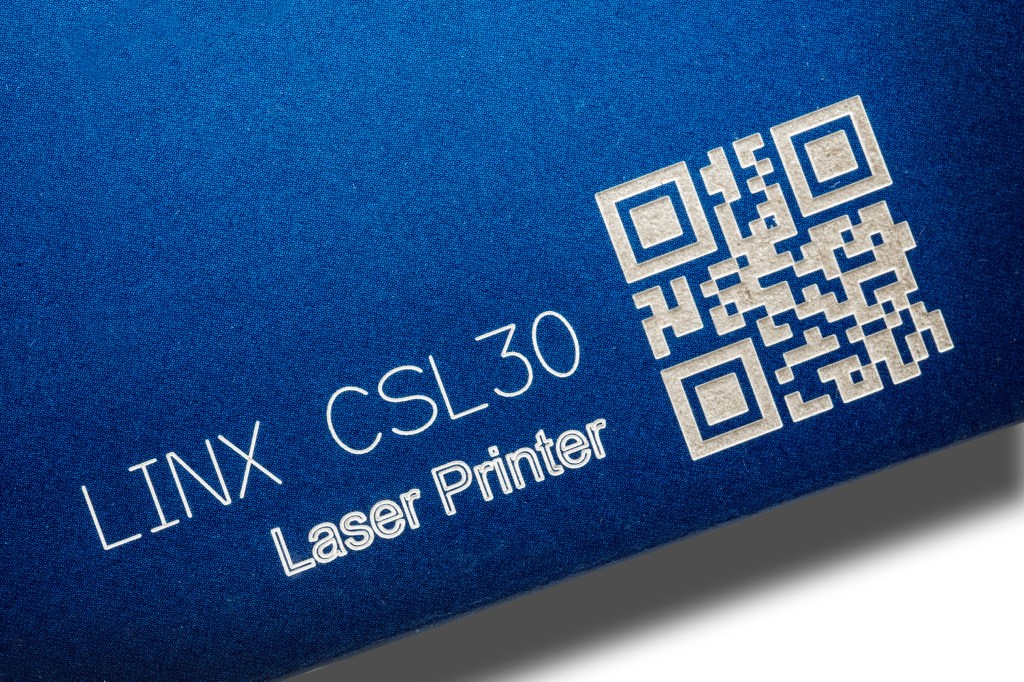

After initial period of using Linx’s laser printer, Wolds installed another two machines to support their new, faster production lines: two Linx CSL30 models. It enabled printing more complex codes much faster on increased line speed, with easy message creation and management of printing parameters using the large colour LinxVision® Touch Screen provided.

Linx solution

“Overall service and customer care received from Linx

Printing Technologies during the initial phase and both

installations were excellent and combined with quality and

reliability of their laser printers allows to build a very strong

relationship for the future”, Wayne Baker, Managing Director.

The Linx CSL30 (30 watt) CO2 laser coder features a powerful

processing board that can quickly relay the message from the

control unit to the marking head. Multiple beam delivery

options allow for coding in any orientation, and the detachable

marking head and quick disconnect cables make integration

into production environments easier.

With the largest range of configurations of marking heads,

lens, and tube wavelength options, Linx CSL lasers can be

fine-tuned to customers’ specific applications.