Linx provides leading-edge solution to ION Science lamps that enhance productivity and cost savings

Linx Laser Coders

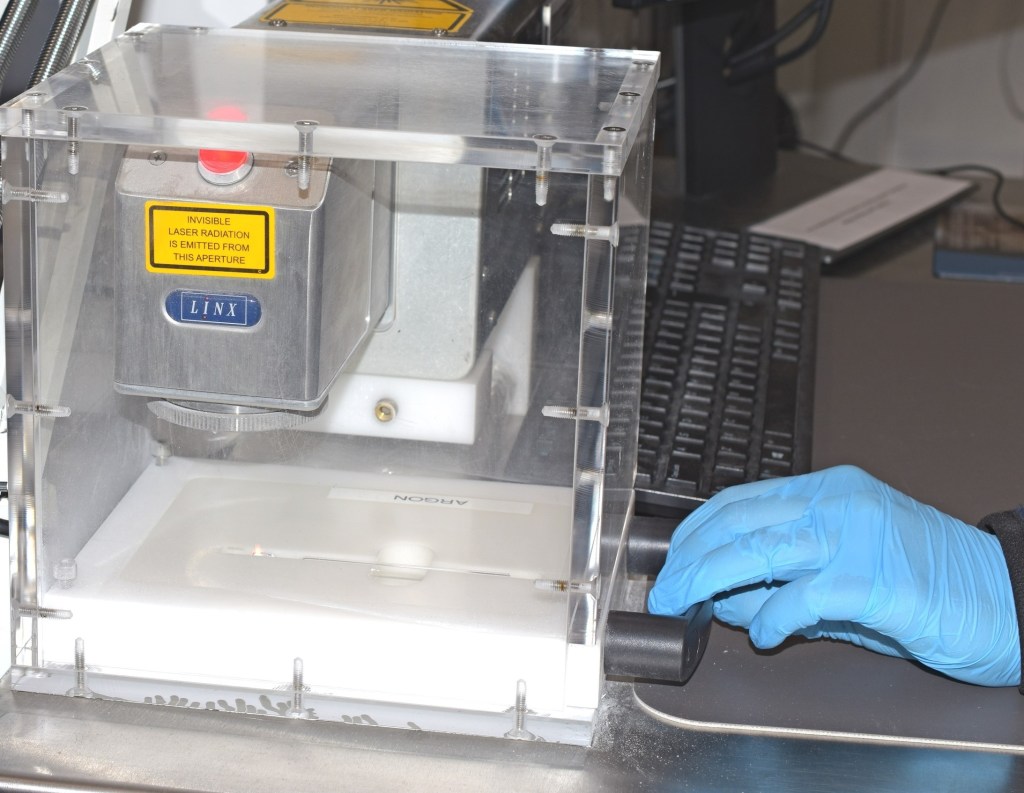

The Linx CSL30 (30 watt) CO2 laser coder is an economical yet versatile machine suitable for a wide range of laser marking applications.

These lasers offer any-orientation coding alongside full touch-screen control, low running cost, minimal maintenance with a bonus of zero consumables. We provide affordable and effective solutions compared to any other marking technologies.

ION Science

ION Science Ltd has been a customer of Linx Printing Technologies Ltd since 2012 and had many success stories and an outstanding partnership since.

Who is ION Science? They are the leading manufacturer of technologically advanced gas detection equipment and OEM PID Gas sensors. Just like Linx, ION Science work with customers and global distributors so it is crucial we work in a high-performance manner and produce high quality outcomes.

ION Science have two Linx CSL30 laser coding machines installed with another on order. These machines are providing a pioneering gas sensing technology company with an advanced and reliable coding and marking solution to support their growth. These printers are designed for high-speed marking for complex codes, perfect for ION’s purpose. Linx CO2 laser coders offer many benefits with another being high reliability from the machine needing minimal consumables and efficient use of laser power to mark permanently.

The Problem:

In light of significant company growth and an increase in demand for their lamps, ION Science realised the need to increase the speed of their production line for etching onto their glass lamps found within their Sensors and Instrumentation for the detection of volatile organic compounds (VOCs). The previous process to laser onto the lamps was slow and involved manually inserting the glass lamp into place, lasering, removing, and replacing it with the next lamp, then repeating the process. ION Science expressed productivity concerns to Linx requesting a more efficient technique.

The Solution:

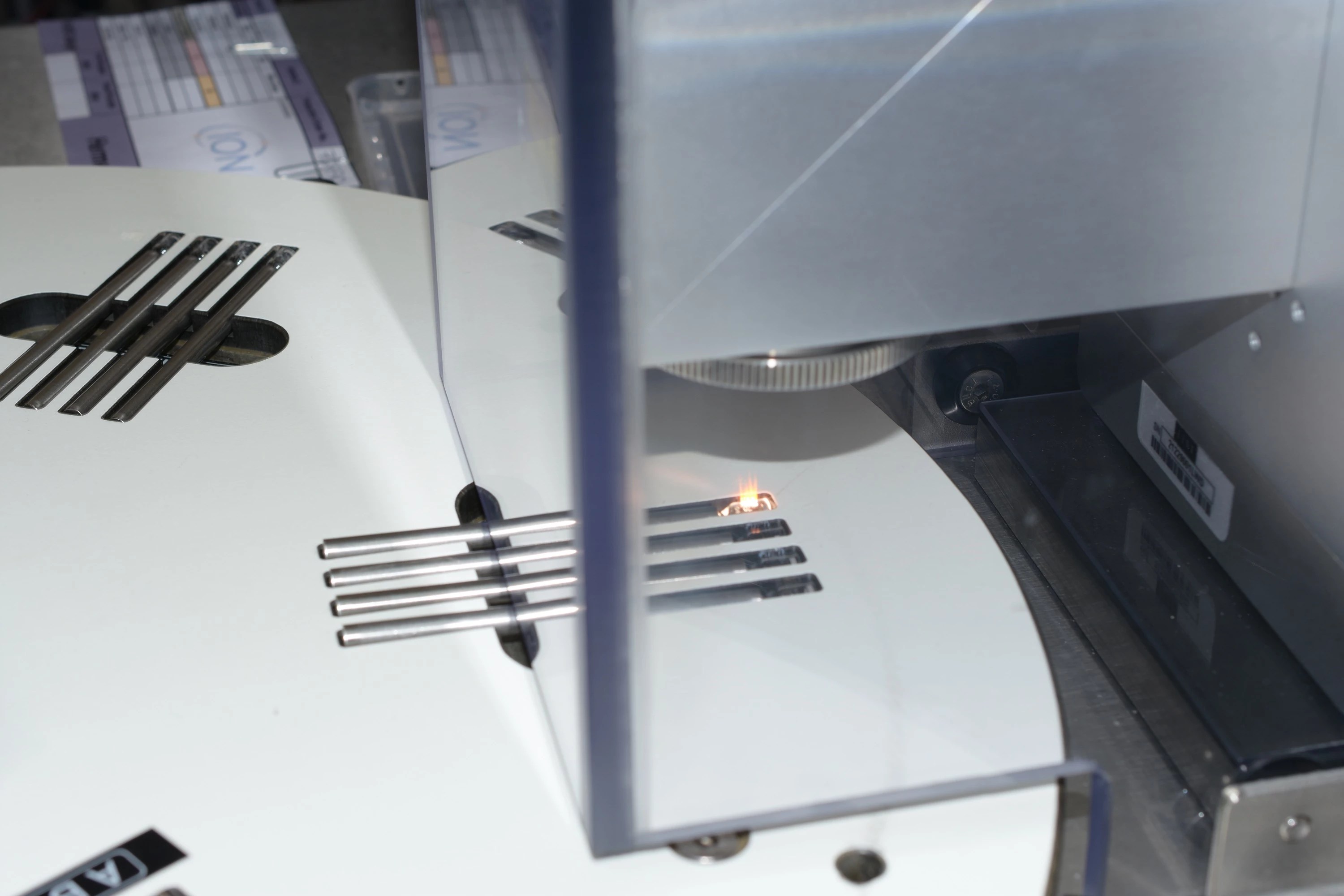

The idea of a turntable to fix the problem was explored and implemented, allowing multiple glass lamps to be placed on the table and laser coded at 4-5 times the rate of the previous method. Linx lasers have versatile beam delivery options for easy integration into a production line making it effortless for ION Science to implement. A bespoke turntable and laser safeguarding were constructed to fit ION’s production line allowing their output to increase significantly. Linx lasers are the future of marking offering clean codes, low maintenance, and low running costs. Our laser developers are always in search of improvement, how revolutionary can we get?

This success story resulted in another laser being ordered. Linx only offer the best customer service and expert advice to all their customers, no matter how big or small the problem may be.

New and improved turn table lasering 4 products at a time

“The turntable solution provided by Linx has significantly transformed the production of etching onto our photoionisation detection (PID) lamps which has dramatically enhanced our productivity and provided us with notable cost savings. The rate of lamp production will help us fulfil demand for our products and achieve our ambitious growth plans.” Brian Carmichael, Engineering Head of Sensors at ION Science