LEAN MANUFACTURING THROUGH CODING AND MARKING SOLUTIONS

Reducing waste and increasing productivity

In today’s competitive markets, many companies are realising the benefits of applying lean manufacturing principles to help increase competitiveness and efficiency.

By using these principles in your product coding and marking operations, valuable savings can be made which contribute towards your Overall Equipment Effectiveness.

This White Paper covers how coding equipment can play a significant role in a lean operation, and factors to consider when specifying new equipment.

Quick Links:

Introduction

Lean manufacturing is about minimising waste, and maximising value-added activities. According to lean principles, each step in the production process should add value for the customer.

Industrial printing and marking is a critical step in the production of consumer products. However, because it is usually driven by legislative or customer requirements for batch traceability or durability information, the process is often considered a non-value added activity, which can lengthen product changeover times and result in lost production.

Nevertheless, the latest developments in printing and marking equipment can help to reduce production wastes in many ways, and actively support lean manufacturing principles.

Examples, which can apply to companies of virtually any size, include:

- Waiting

- Quality defects

- Over-processing

- Over-production

- Transportation

- Inventory

- Motion

- Unused creativity

Linx customer research includes an example where the move from labelling to digital printing at a fruit and vegetable packaging operation increased throughput by 230%.

Similarly, a pet food manufacturer doubled its output through the ability to apply more data to the pack. This speeded up product changeovers, reduced pack inventory and enabled the company to run on-pack promotions for even greater added value.

Lean Manufacturing

A lean company will constantly strive to focus on the value of what it does for its customers, mapping its processes right across the business, from generating the order for a product to the end delivery of that product.

This enables companies to identify and minimise the things that don’t add value or which generate waste.

This creates benefits in a number of ways:

- Flexibility and the ability to respond more quickly to customer demands

- Higher quality of work

- Lower costs

- Increased production throughput

Overall Equipment Effectiveness

Many companies are already embracing lean principles by focusing on Overall Equipment Effectiveness (OEE), which aims to reduce or eliminate the six ‘big losses’ that cause inefficiency in manufacturing. These are: breakdowns; setup and adjustment; small stops; reduced speed; startup rejects; and production rejects. These are exactly the sort of ‘wastes’ that lean manufacturing seeks to minimise.

As well as productivity, other key elements of OEE are quality and reliability. All three of these elements can be supported and enhanced by the use of the right printing and marking equipment.

Equally important, while the information printed onto products is often carried out for legislative requirements, or for companies’ own tracking systems, the ability of industrial printers to deliver the required level of compliance is a key element in achieving improved brand protection.

How coding and marking can help

The benefits delivered by modern coding and marking systems in promoting lean manufacturing cover a number of areas:

Improved brand protection/compliance

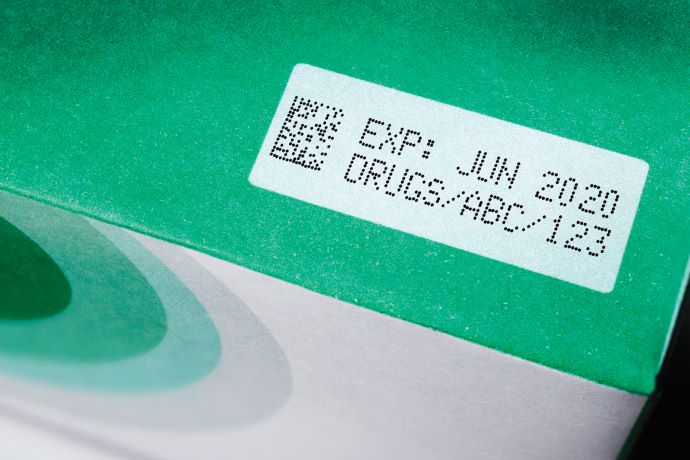

High resolution, long-lasting quality codes for information such as use-by dates, batch or traceability data, will not only ensure that your products meet all the necessary legislation or customer requirements, but will complement your product and make sure they do not detract from its overall appearance or image.

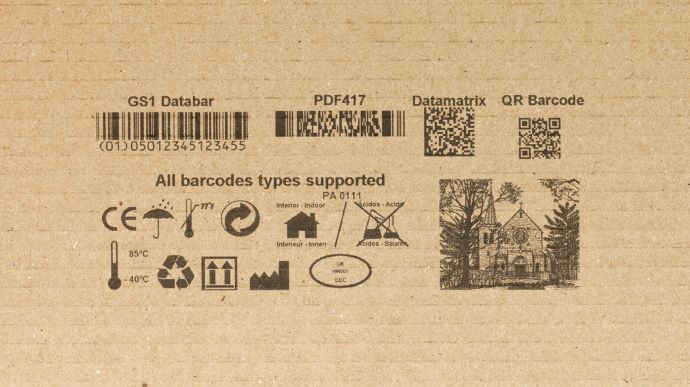

The choice of equipment available, such as Continuous Ink Jet (CIJ) printers, laser marking systems, thermal inkjet printers or large character printers, means it is possible to select a solution for your particular packaging material or substrate which will print the type of information required, from simple one or two line messages to more complex 2D codes, graphics and logos.

Quality

Printing and marking equipment that is reliable and easy to set up and use will contribute to an efficient operation.

Errors can be costly – in terms of lost time, lost product, the need for reworks and the possibility of a product recall and retailer fine. Modern printers offer simple message creation and editing, ensuring consistency and reducing the likelihood of mistakes and reworks on the factory floor. Touch screen user interfaces, often using picture-led prompts, and on-screen help deliver further benefits for users.

Another way to reduce inadvertent tampering and errors in coding is by transferring code content between printers using a USB, while different users can be assigned different levels of permission to create, select or change messages.

Barcode scanners linked to printing and marking equipment can allow automatic code selection, while individual or multiple machines can be managed and monitored from a central computer or even a smartphone.

Productivity

Coding and marking systems can help to minimise product waste and increase manufacturing uptime in several ways:

Reducing stoppages

Machines that are easy to integrate into production lines mean less downtime during the installation process. For challenging environments, selection of a printer with the appropriate IP rating will avoid failures caused by ingress of solids or fluids into the machine.

Features such as self-cleaning printheads reduce blocked nozzles. Timely and visible notifications of low fluid levels allow refills to be actioned in good time to avoid unplanned stops to the line.

Planned stoppages can also be minimised through the use of modern printers with long service intervals, and self-servicing and self-maintenance models, with mistake-proof consumables changes. Machines designed for use in washdown production environments save time covering or removing them for cleaning to take place.

Reducing waiting time

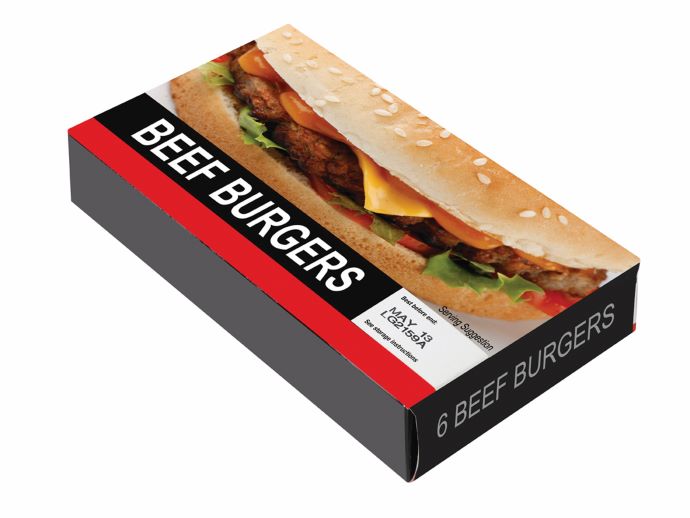

For manufacturers needing frequent or fast product changeovers, digital coding and marking technology allows multiple messages to be stored, which can then be selected at the press of a button, reducing the time spent setting up new data and information compared to, for example, changing rollers or plates on non-digital machines.

Multiple line settings as well as data held in the printer’s memory mean information specific to product lines can be set up and indexed in the machine, making for quick product changeovers Lightweight machines can be moved between lines and set up quickly, making them more flexible in their use and reducing setup times.

Reducing processes and over-production

Technology which requires minimal startup procedures and where the first print is as good as the last means there is no need to leave machines switched on permanently, or to run them every day.

Machine versatility will enable manufacturers to use one model for several applications, printing onto a range of substrates from plastic to tin, glass or cardboard.

Less variation in machine types also leads to fewer instructions to learn and a reduced inventory of consumables.

Flexible printheads which can print in any direction – even from underneath the product – mean there is less manual handling required of the product, or additional equipment to re-orientate the product for coding.

Reducing waste

Coding and marking systems that combine quality and accuracy will help to minimise waste by ensuring the correct information is printed every time, that it is legible and in the right place on the product.

Factors to consider in the selection of a coder

Choosing the right printing and marking solution is not easy. No two applications are exactly the same and the following are all factors to be considered when deciding what type of equipment to choose:

Information required

Will increased complexity such as additional lines of print, or printing in different orientations be supported by the printer you choose, or will you need to purchase another model?

Substrate

Consider the range of materials on which you need to print or mark. Ensure that you have each of these sample-coded by the printers you are considering. Is the data legible? Also consider the range of colours of the materials to be printed onto: could one coding solution be suitable for all?

Line speed

Will the machine keep up with your line speeds? Will the print be compromised if it cannot? Do you need to print or mark across multi-lane production lines now, or will you need this capability in the future?

Factory environment

If your working environment is hot and dusty or cold and damp, for example, ensure that your solution has the right IP rating and features to perform reliably.

Available budget

Not just the initial purchase price, but consider the overall cost of ownership and factor in reliability; by compromising on price you may pay more with unexpected breakdowns. Is leasing a better option, as a revenue rather than capital cost? During peaks in production, will rental give you flexibility to meet demands?

Testing

Will your equipment supplier offer a free trial? You need to be sure the machine is capable of meeting the demands you will put on it.

The different industrial coding and marking technologies

There is a range of technologies available, each with its own particular strengths in different applications, but all capable of reinforcing lean manufacturing. Digital printers in particular are more adept at fitting into a manufacturing environment, rather than a production line having to be fitted around the machine, which in itself can cause several wastes.

Laser

Laser marking applies a permanent code on a wide range of materials at high line speeds. As there is no ink involved in the process and therefore no drying time, the process is speeded up.

Laser systems are particularly attractive due to their low downtime, high-speed capability and the fact there are no consumables; which together make the long-term cost of ownership lower than some other technologies.

Developments in design have also recently given rise to a new generation of lower cost compact lasers, which offer an affordable alternative to other technologies while still maximising functionality.

Continuous Ink Jet (CIJ)

Perhaps the most cost-effective choice, CIJ maintains an important place as it can print on almost any substrate. A wide range of inks is available to use with CIJ printers including inks of different colours to ensure legibility on any colour substrate, UV-readable inks for anti-counterfeiting or water-removable inks for internal traceability, adding yet another dimension to the printing process.

CIJ can print from one to multiple lines of text and simple graphics at speeds of over 2600 characters per second. Further versatility is given by the compact printhead that can be situated above, beside or beneath a production line – even traversing from side to side across the line if necessary, and so reducing manual intervention or additional processes.

With lighter models increasingly being produced, the CIJ printer is more capable of being moved quickly from line to line and is quicker to install and set up than laser systems.

Large Character Printers

Large Character printers are particularly well-suited for printing variable information onto secondary packaging such as cardboard boxes. These outer cases usually require text and graphics which are easy to see.

The printers can print to a high-resolution quality, and are versatile enough for use on a variety of surfaces and materials.

Easy to set-up and adjust, their reliability and predictable cost of ownership endear them to production lines in a range of industries. They are also a very cost-effective alternative to pre-printed boxes or labels.

Thermal Inkjet (TIJ)

TIJ printers provide a flexible solution for both outer cases and primary packaging.

Although offering a smaller print area than case printers, these high resolution machines generate superb print quality for premium packaging, and are a cost-effective solution for slower production lines or where production is not 24/7.

Conclusion

Industrial coding and marking equipment can play a significant role in a lean operation. However, with so many different models available, it is always wise to run a trial with any machine to make sure it is delivering the savings you want. And do not just look at the printer in isolation – it is how it can contribute to minimising waste throughout the whole operation that counts. In the same way, assess any equipment on its total cost of ownership and all the benefits it brings.