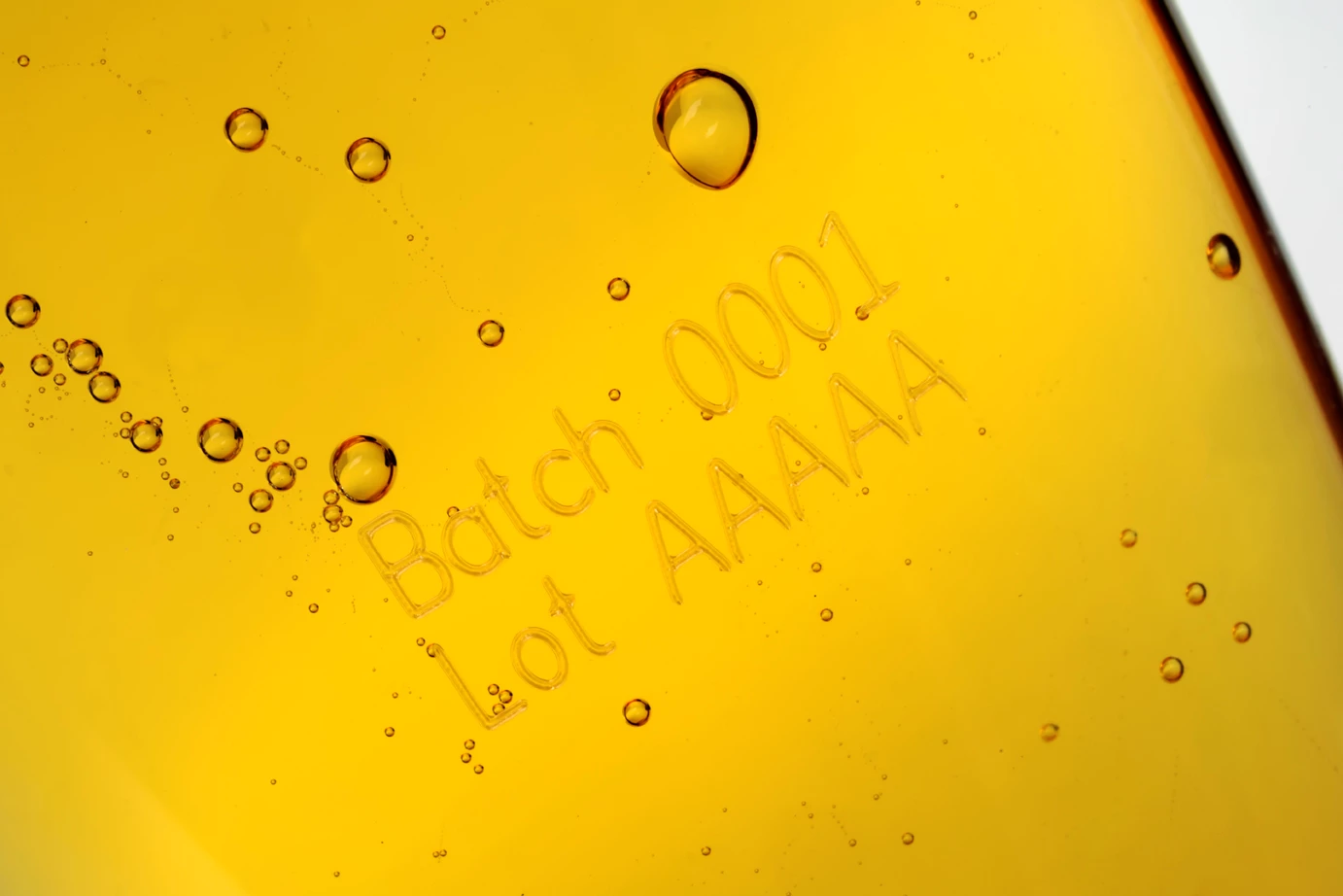

Batch & Lot Coding

Batch coding (also known as lot coding) is a critical part of traceability. Linx has a range of lot code printers capable of printing onto nearly any type of packaging at high speed with multiple lines of text even in harsh production environments.

The Food and Drug Administration (FDA) defines a lot code as “a specific identified portion of a batch, that is uniform and that is intended to meet specifications for identity, purity, and composition”. Regulations are continuously strengthening to protect consumers and producers across many industries must take care to ensure that their batch numbers or lot codes are legible and consistent.

Lot Number Printing

Our automatic coding machines are designed to print batch and lot numbers that are clear and durable directly onto manufactured goods or packaging. Ideal to ensure batch traceability, for tracking parts between production locations or to safeguard against product recalls.

Every Linx lot number printer is designed with you in mind and can be set up with ease via our user-friendly interface, with most models offering smartphone-style touchscreen operation.

Options are available for any production environment like our popular continuous inkjet printer, the Linx 8900, with ingress protection (IP) rating suitable for dusty or wet conditions and permanent marking with our laser lot coders and batch coding machines.

Contact Us

Why not get in touch with one of our sales reps to talk about how Linx can support your coding and marking needs?

Lot & Batch Number Printers

Inkjet Batch Coding Machines

Linx CIJ printers are designed to be durable and full-featured, meeting the highest standards of coding quality.

- Range of inks for specialist marking, e.g. food grade, invisible/UV coding

- Optional IP protection for harsh environments

Linx wide range of inks will keep batch codes in place on nearly any substrate and can withstand harsh production environments whilst offering non-contact, multi-line coding.

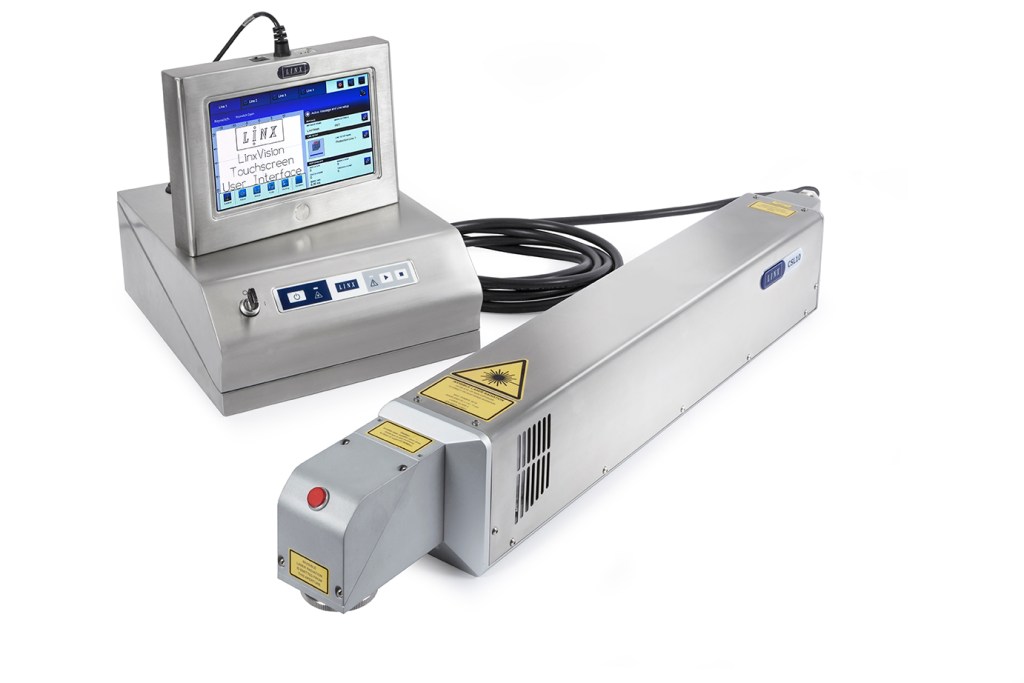

Laser Batch Coding Machines

Laser printers are ideal for reliable batch coding, with no need for consumables, lasers provide a low operating cost product marking solution with permanent batch codes.

- Permanent marking capability

- Optional IP protection for harsh environments

Linx laser batch coding machines are designed for use in challenging, high-speed production environments while ensuring industry leading text and code quality.

Packaging Batch Printers

With the ability to print clear text and graphics onto porous substrates, Linx Large Character Inkjet Printers are a cost-effective alternative to labels and pre-printed boxes.

- Ideal for packaging printing

- Code text and graphics

These high-resolution batch printers guarantee efficiency and quality when printing on difficult packaging substrates.

Thermal Batch Printing Machines

Linx Thermal Transfer Printers guarantee a cost-friendly and user-friendly experience, without sacrificing print quality.

Using clutchless ribbon drives, the risk of ribbon breaks is minimal, maximizing production uptime. This simple printer can fulfil batch marking needs in industries ranging from pharmaceutical to food production.

- Wide range of marking types

- Suitable for flexible materials e.g. paper, film

Batch Coding Applications

Resources

Beavertown Brewery

Parkinson Harness Case Study