Batch Coding

Our batch code printers are all designed to print clear and durable batch numbers directly onto products, manufactured goods and packaging. Whether you are tracking a part between production sites, ensuring traceability or safeguarding against recalls, you can ensure reliable product identification with the highest quality lot codes using Linx batch printers.

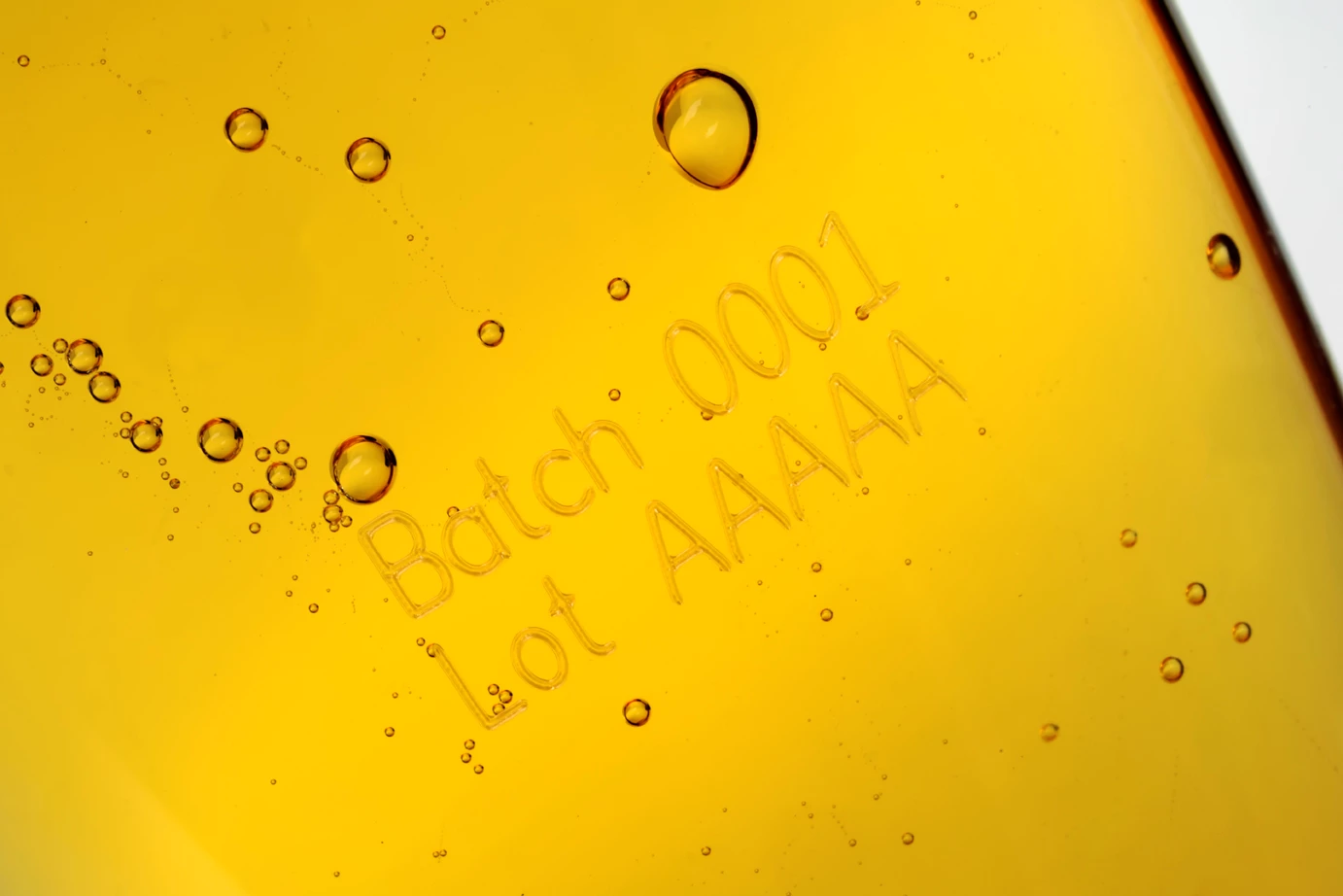

Printing Batch & Lot Codes

Options are available for every production environment, laser batch coders offer a permanent marking solution and our popular continuous inkjet printer, the Linx 8900, is capable of coding in a variety of ink colours. Both are available with IP ratings suitable for dusty or wet environments.

With Linx, batch coding becomes an integrated and reliable part of any manufacturing process.

Industries printing batch codes

Batch codes are widely used across many industries as they are the most popular method of ensuring traceability. Industries such as:

These are the ones where batch code printing is key, where consumer safety is paramount and reliable product identification through legible batch codes is vital. However, no matter what industry you are in, you may need to ensure that you have a robust method of identifying your own products – that’s what Linx can help you with!

Request a Print Sample

See what your code will look like.

To find out more information and to request your samples with no obligation, click the button below.

Batch Code Printers

Every Linx batch coding machine is designed with you in mind, you can print batch numbers clearly and consistently using coding templates. Each printer provides a user-friendly interface, with most models providing touchscreen operation.

Continuous Inkjet (CIJ) Printers

Linx CIJ printers are designed to be durable and full-featured, meeting the highest standards of coding quality.

Linx wide range of inks will keep batch codes in place on nearly any substrate and can withstand harsh production environments whilst offering non-contact, multi-line coding.

- Range of inks for specialist marking, e.g. food grade, invisible/UV coding

- Optional IP protection for harsh environments

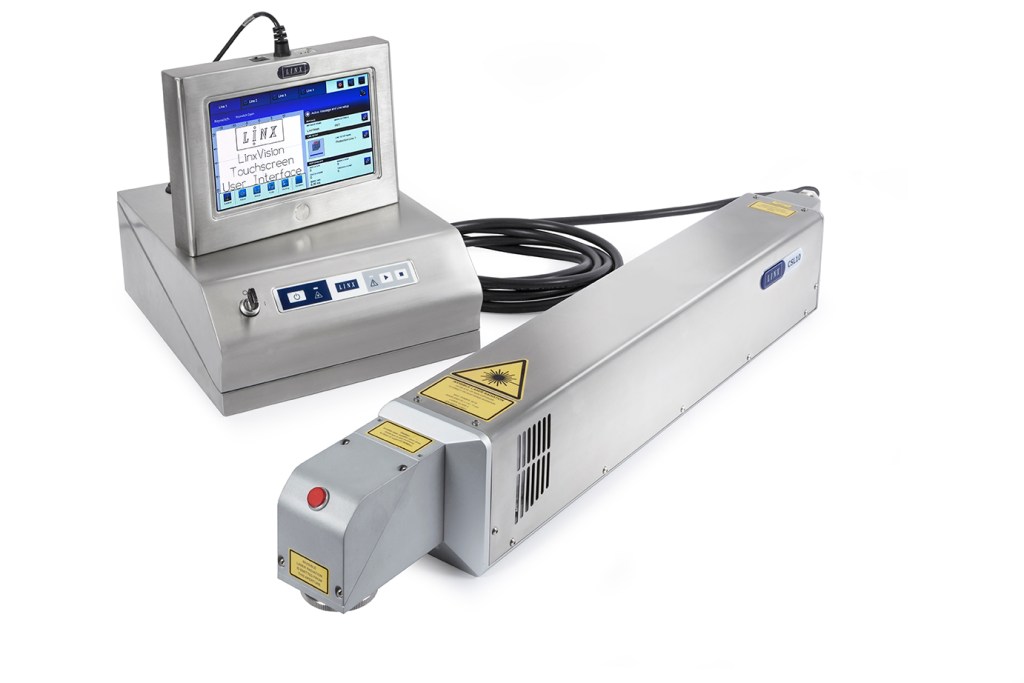

Laser Printers

Laser printers are ideal for reliable batch coding, with no need for consumables, lasers provide a low operating cost product marking solution with permanent batch codes.

Linx laser batch coding machines are designed for use in challenging, high-speed production environments while ensuring industry leading text and code quality.

- Permanent marking capability

- Optional IP protection for harsh environments

Large Character Marking Printers

With the ability to print clear text and graphics onto porous substrates, Linx Large Character Inkjet Printers are a cost-effective alternative to labels and pre-printed boxes.

These high-resolution batch printers guarantee efficiency and quality when printing on difficult packaging substrates.

- Ideal for packaging printing

- Code text and graphics

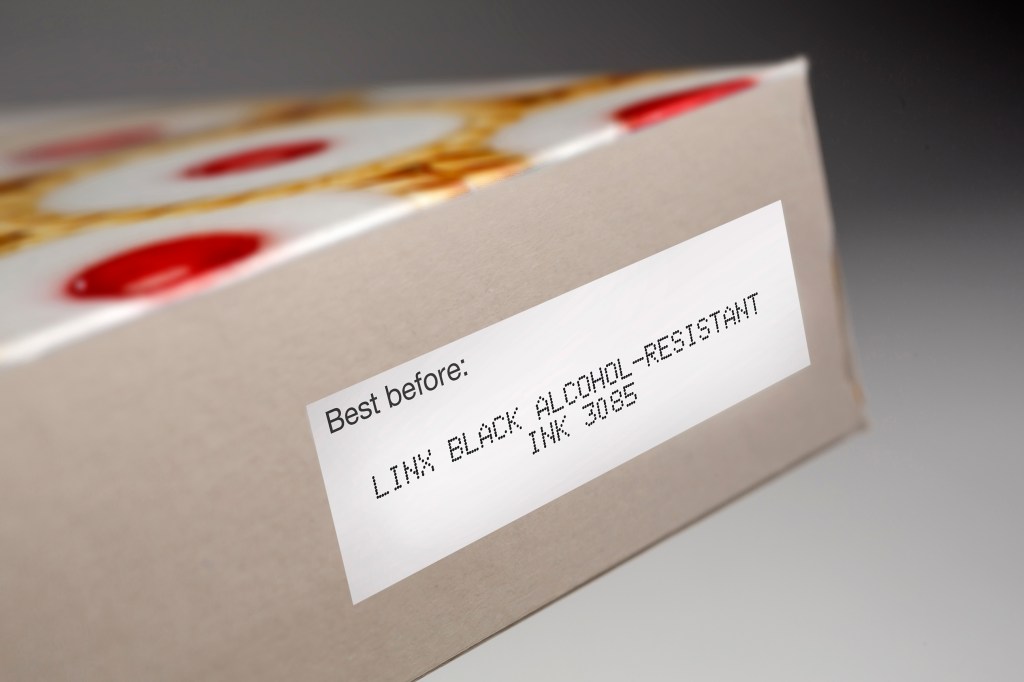

Inks suitable for batch code printing

When using CIJ printers to apply batch codes onto your products, you have a variety of inks to choose from:

- General-purpose black inks

- Food grade inks

- Coloured inks

- Security (UV readable) inks and many more.

We also offer solutions/make-up suitable for our CIJ printers.

Depending on the substrate you are printing on, the environment of your production and the additional outcome you want to achieve from your batch codes printing (i.e. anti-counterfeiting), Linx offers inks that will allow you to apply high-quality, robust and durable batch codes.

This is a process of marking a product with an identifying code. This code is used to identify the product and for traceability.

This is a common term used by operators for the coding machine. It is used to print batch numbers on the product

For non-contact batch coding where the machine does not physically meet the surface of the product and alternatively use lasers and ink sprays to apply a code. The machines best suited for this method would be a Continuous Inkjet (CIJ), Thermal inkjet (TIJ) and Lasers.

Working with Linx

Contact a Linx representative today to discuss your batch coding requirements and find the ideal machine for your needs. Tell us what substrate you want to print batch codes onto and we will propose a solution suitable for your production process.

Batch Coding Applications

Paper & Card

Exceptional quality graphics, text and barcodes onto porous secondary packaging such as bags, trays and boxes.

Resources

Beavertown Brewery

Parkinson Harness Case Study

Related Coding Solutions

Barcode Printer

Printing a clear barcode is an important component for many packaging processes

Date Coding

Programmed formats, automatic date forward functions, and custom date and time editors for a full range of date coding capabilities with expiry date printer