Coding and Marking in Beverage Production

Beverage coding and marking solution

Quality coding and marking is essential to enable drinks manufacturers to meet regulations and protect their brand. Only with accurate, durable codes that print clearly even onto wet surfaces can beverage companies trace their products once they have left the factory.

We offer a full range of beverage marking printers designed to meet the challenges faced by the beverage industry every day such as coding onto wet bottles without sacrificing high line speeds and robust traceability, as well as plastic, glass bottles and labels and more.

Whether you’re coding best before or manufacturing dates, traceability codes, or anti-counterfeit/brand protection marks onto bottles, bottle caps, cartons, cans or plastics – we can meet your specific needs.

Quality coding to protect your brand

- ‘Invisible’ UV-readable codes offer discreet coding for internal traceability as well as anti-counterfeiting

- Permanent laser coding of complex logos, circular text and 2D codes directly onto bottles make hard work for copycats

- White, yellow, grey or light blue contrasting inks provide legible codes even on dark glass or PET

Reliable operation in challenging environments

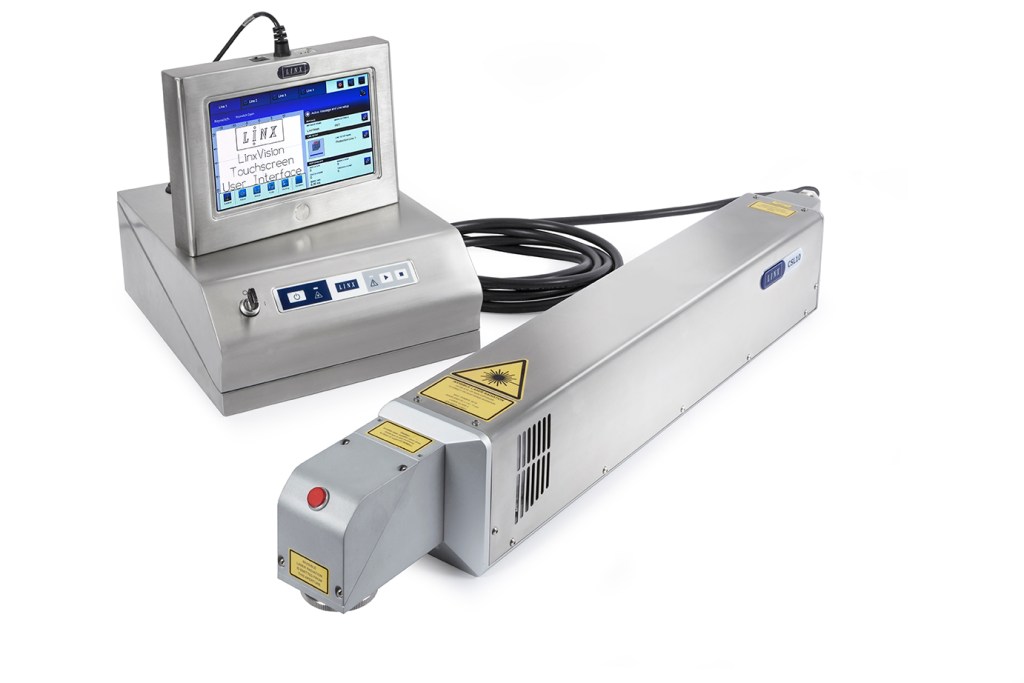

- Protection against water ingress during production or CiP processes – Linx 8900 ink jet printers and CSL laser coders both have stainless steel enclosures with IP55 rating as standard

- With the Linx 8900, long service intervals of up to two years and minimal cleaning means more uptime on busy 24/7 lines

Maximise productivity

- Powerful laser coders for high-speed bottling lines – coding up to 70,000 bottles per hour

- Print both primary and secondary codes with the Linx 8900 – ideal for bottles/cans as well as outer cases

- Spend less time monitoring your printers and accurately predict end-of-batch runs with Linx Printernet

Applications used in Beverage Industry

Bottle Printing

Machines for printing on glass and plastic bottles, from household products to drinks and cosmetics.

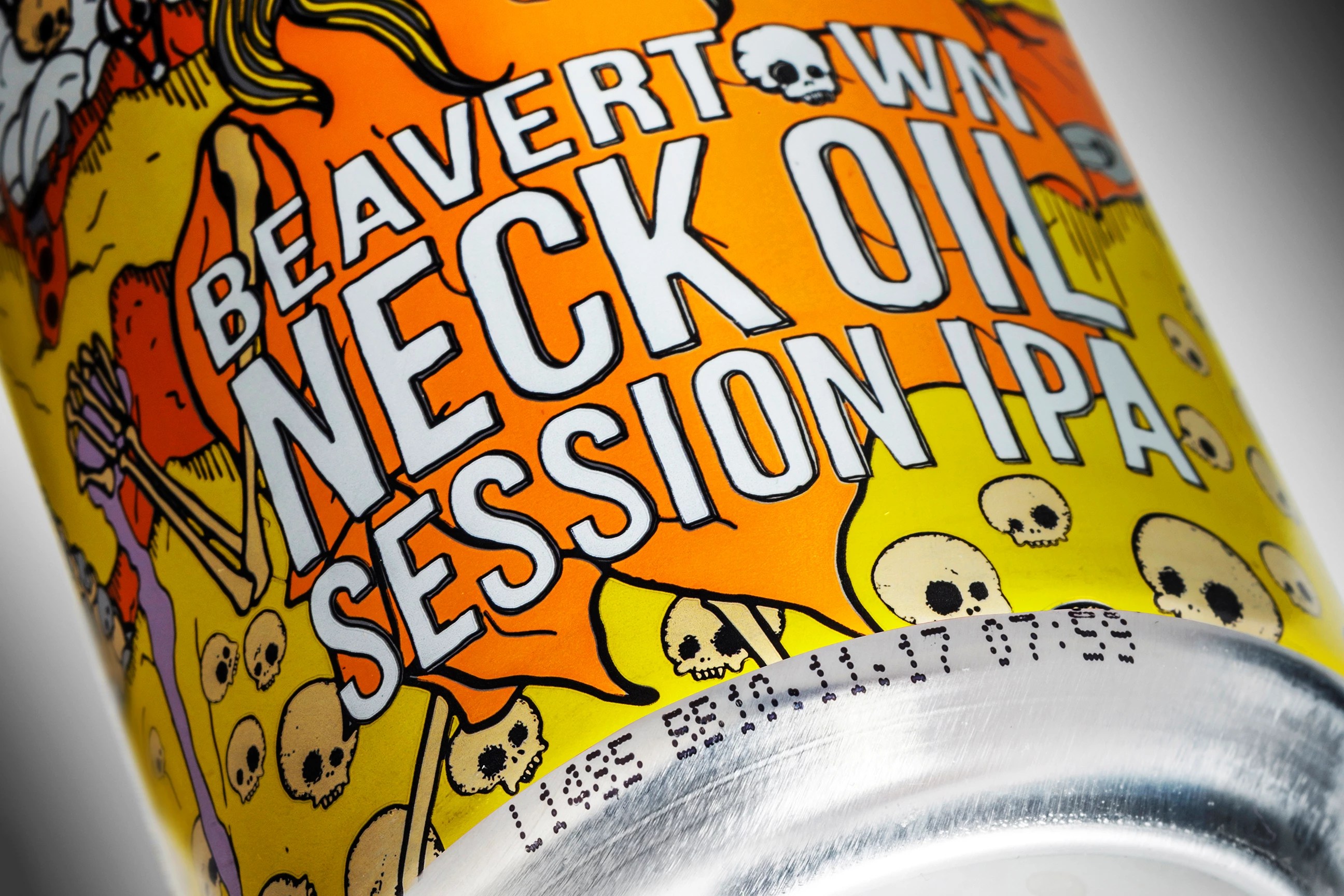

Can Coding

Solutions for coding on glass and plastic bottles, from household products to drinks and cosmetics.

Printer Types for Beverage Industry

In selecting the most appropriate coding and marking solution for beverage products, there are a number of factors to take into consideration:

- Code content. What do you need to code currently and will any changes in requirements – for example, increased code complexity, such as additional lines or printing in different orientations – be supported by the printer you choose?

- Substrate. Consider the range of materials and different colours you need to code onto

- Line speed. Will the coding solution keep up with your line speeds? Will the print be compromised if it cannot?

- Factory environment. If your coding environment is wet or dusty, ensure that your coding solution has the right IP rating to perform reliably.

Before you commit to a solution, it is important to have each pack material sample-printed to check how well it works. A trial of the printer on the production line is also worthwhile, ensuring it is exposed to real-life production factors such as speed, dust, or moisture.

Get high quality, highly visible coding directly onto glass, plastic and metal, or onto labels and sleeves with Linx CIJ and laser coding solutions using adhesive inks, or lasered directly into the surface of the glass. Our coding experts can advise you on the best solution from our range of marking machines for the beverage industry. We can help you to reduce waste, maximise production throughput and meet deadlines.

Continuous Inkjet (CIJ) printers

CIJ maintains an important place in the beverage market, as it can print on almost any substrate including plastic bottles, metal cans, glass or enclosures. From cardboard to glass, plastics to metal, CIJ can print from one to multiple lines of text and simple graphics at speeds of over 7m/s for a single line of code. Further versatility is provided by the compact printhead that can be situated above, beside or beneath a production line – even traversing from side to side across the line if necessary. With lighter models now available, the CIJ printer is more capable of being quickly moved from line to line and is quicker to install and set up than laser coders.

Linx CIJ Printing solutions can help to maximise production time between multiple SKUs with quick, error-free code changeovers while line setups can be stored and retrieved for repeat work.

The Linx 8900 Series printers are designed to make operation and efficiency easier than ever and will support your business with:

- Meeting your output targets

- Reliable, continual operation

- Traceability of your products

- Meeting compliance requirements

- Remote printer monitoring and proactive support

Laser coders

Laser coding has no ink involved in the coding process and therefore no drying time and no risk of smudging, which can be an issue on some materials where the coded product may be in contact with other products or handling systems soon after coding.

Laser coders are suitable for all the substrates used in the beverage industry, and at high line speeds.

CO2 laser coders are the most popular lasers in the beverage industry as they are very adjustable.

Fibre lasers are now starting to be seen as viable options, as they can code onto bare metal such as that used for canned drinks.

- Minimal maintenance, low down time, high-speed capability and no consumables – cost effective solution

- Codes can be highly visible or discreet, an ideal permanent solution in the fight against counterfeiting

- Highly versatile as they provide clear, consistent and perfectly formed characters in a variety of fonts and message formats, even over relatively large print areas

Inks and Solvents for Beverage Industry

Inks that penetrate condensation to mark both glass and plastic bottles are available with continuous inkjet models. These are particularly well-suited to cold fill applications and those where bottles are stored outside before being brought inside to fill, causing condensation. Such inks also perform equally well where condensation is not present, saving companies with multiple products the need to store different types of inks and have different printers for individual applications. For coding onto dark materials such as coloured glass or plastic, white, yellow, or blue inks are available to provide contrast and therefore enhanced legibility. In this case, one ink could also suit all a manufacturer’s coding requirements, as a light blue, yellow or white ink will also show up well on clear substrates.

A wide range of inks is available to use with CIJ printers, such as:

- Different coloured inks for legibility on coloured materials

- Removable inks for returnable bottles, saves significant amounts of energy and resources – over and above even the benefits of recycling

- Wet-bottle adherent inks for cold-fill applications

- UV-readable inks for anti-counterfeiting or internal traceability by bottle manufacturers.

Contact Us

Why not get in touch with one of our sales reps to talk about how Linx can support your coding and marking needs?

Resources

Coding & Marking Solutions for Alcoholic Beverages

Beavertown Brewery

Special Adherence Inks Datasheet

Bruichladdich Distillery Co. Ltd Case Study

Top Ten Tips for chosing the right coder

Beverage Infographic