Bottle Printing

With many years of experience in creating coding and marking equipment, we understand that printing on bottles presents a number of unique challenges, from difficult-to-adhere surfaces and wet or dusty environments to small circumference marking areas and post-marking sterilisation processes. Linx coding technologies have been specifically designed to meet these challenges.

Linx Printers are ideal for high-volume expiration date coding or batch identification and are designed to print directly onto plastic or glass bottles in almost every orientation. With a range of pre-programmed codes, they can mark variable information as well as print barcodes, DataMatrix and QR codes onto bottles avoiding unnecessary waste and the environmental impact of pre-printed labels.

Linx bottle printing machines are used in a wide range of industries from food, beverage, cosmetics and FMCG household products to pharmaceutical & chemical bottling. Our expertise in product and packaging marking & identification can help you to reduce costs and improve production rates.

Coding and Marking on Plastic (PET) Bottles

Polyethylene Terephthalate (PET) is one of the main materials used as a liquid container in carbonated soft drinks, and bottled water amongst others, due to its inherent properties of strength, flexibility and transparency.

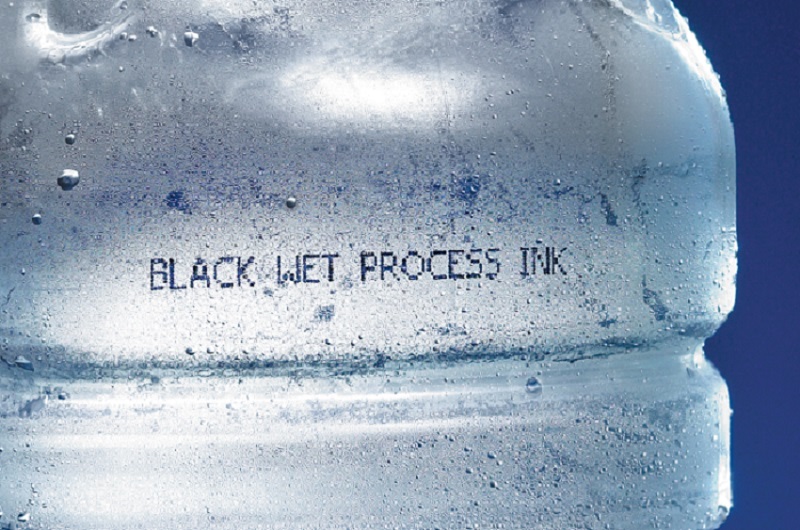

The two primary technologies for coding on PET are Continuous Inkjet Printers (CIJ) and CO2 Lasers. Linx Printing Technologies offers a diverse range of CIJ ink formulations that provide quality codes onto plastics including PE or PET, polypropylene (PP or OPP), PVC and Nylon. And laser systems for high-resolution, permanent marks with no need for consumables or ribbon/ink changeovers.

Continuous Inkjet Printers for Plastic Bottles

Linx’s CIJ printers provide accurate, non-contact printing properties for any bottle shape. The diverse selection of inks includes water and oil-penetrating, fast-dry and plastic-adherent – designed for a range of CIJ printers, to meet your coding speed and production needs.

- Durable, high-quality printing for any bottle shape

- Various models available to match your production speed and needs

- Range of inks for specialist marking, e.g. water and oil-based, fast-dry and plastic-adherent

- Designed to integrate with your production line systems

Laser Marking Machines for Plastic Bottles

Linx’s CO2 Lasers can deliver a unique frosted effect on a bottle to produce a visible, permanent code. However, choosing the right laser requires matching the laser wavelength to the PET’s thickness. To make this match our laser experts will help with evaluating the substrates, provide marked samples, and make recommendations to meet the code and speed requirements.

- Permanent laser marking solution

- Wavelength options available to match the PET thickness

- Unique frosted effect on a bottle to produce a visible, permanent code

- Models available to engrave even on thin plastic surfaces to preserve the structural integrity of PET bottles

To avoid deep engraving of thin plastic surfaces, and to preserve the bottle’s structural integrity, Linx’s CSL 30 with a 9.3µm wavelength tube, is ideal to help meet maximum throughput with consistent mark quality on lightweight PET bottles.

Coding and Marking on Glass Bottles

Glass bottles are a popular package option for a number of reasons, being the identification of a premium product and that of a strong protective barrier to a variety of food and beverage products.

From high-condensation environments to high-speed lines, beverage producers operate with some of the most critical conditions. Linx Printing Technologies offers a broad range of Continuous Inkjet (CIJ) printers and Laser solutions for coding on glass bottles.

Our laser machines are suitable for etching information such as serial numbers, internal tracking numbers and traceability information on clear or coloured glass. Codes etched on glass are permanent, visible and easy to read, which is especially important in the food and beverage industry.

Continuous Inkjet Printers for Glass Bottles

CIJ printing is one of the most adaptable and durable options for beverage manufacturers using glass bottles. Depending on your needs, Linx have high adhesion, retort and even washable inks for printing onto glass surfaces in a range of harsh environments and to enable straightforward recycling of the glass after use.

- Most adaptable and durable option for beverage manufacturers using glass bottles

- Effective and durable coding even in harsh environments

- High adhesion, retort and even washable inks for printing onto glass surfaces

- Enables recycling of the glass after use

Laser Marking Machines for Glass Bottles

Linx lasers have the widest selection of marking heads, lenses and tube options to meet individual materials, line speeds and code requirements, especially for glass bottles.

Laser coders will improve the contrast and readability of your codes by providing crisp, permanent, and precise printing on glass surfaces, even at high line speeds.

- Permanent laser marking suitable for luxury goods and anti-counterfeiting product identification

- Precise printing on glass surfaces, even at high-line speeds

- The widest selection of marking heads, lenses and tube options to meet individual materials, line speeds and code requirements

Coding and Marking on Bottle Caps

Many industries require coding of date/time and batch or lot numbers onto the bottle cap, rather than onto the bottle or label which often presents challenges of small circumference and hard-to-code materials.

Our bottle printers are also capable of printing onto metal or plastic caps with small character printing that is legible and consistent.

Request a Print Sample

See what your code on a bottle will look like.

To find out more information and to request your samples with no obligation, click the button below.

Production Line Bottle Printers

Bottle based production often requires high volumes, at Linx we realise that reliable and consistent product marking is critical as rework adds unnecessary cost to product manufacture.

Our bottle printers and coders are designed to integrate with production line systems, able to cope with a variety of line speeds and with automated date, time, code & number series functions reduce manual interventions and therefore avoid line downtime.

We also have models capable of static marking and offer specialist coding solutions like UV visible inks or permanent laser marking suitable for luxury brands or anti-counterfeit product identification.

Glass Bottle Printing Production Line

Related Applications

Remotely manage your bottle printing through Linx cloud-based monitoring.

Linx PrinterNet

Need help choosing the right solution?

Contact us now and your local Linx printing & marking expert will call you to discuss your printing requirements and provide you with a quote. Alternatively, fill in a Contact Us form or chat with us using the web chat facility.

Resources

Coding and Marking Solutions for Beverages

Beavertown Brewery

Decantae Mineral Water

Bruichladdich Distillery Co. Ltd Case Study

Top Ten Tips for Choosing the Right Coder

Special Adherence Inks Datasheet