Don’t underestimate the impact of Total Cost of Ownership

This is the second in our series looking at reducing operating expenses and here we will be examining what is ‘Total Cost of Ownership’ (TCO), why it is so often overlooked and undercalculated and what you should consider in your TCO calculations.

Let’s make sure we are talking about the same thing. What is Total Cost of Ownership?

To paraphrase the definition by Techopedia, TCO is the

“financial estimate of all direct and indirect costs associated with a

purchased asset over its entire life expectancy”.

So, a more holistic view of ‘cost of purchase’ – a strategic approach to procurement – allows you to accurately compare various offerings. If you only take the purchase price into account, you will underestimate the true cost over the lifetime of the equipment, and your ROI (return on investment) could be severely reduced.

Why is TCO often overlooked or undervalued?

There are suggestions that there is a lack of understanding of how easily TCO can be calculated. But production teams, along with finance and procurement, have evolved the discipline to the point it is now best practice to take a broader view in order to make a more informed choice.

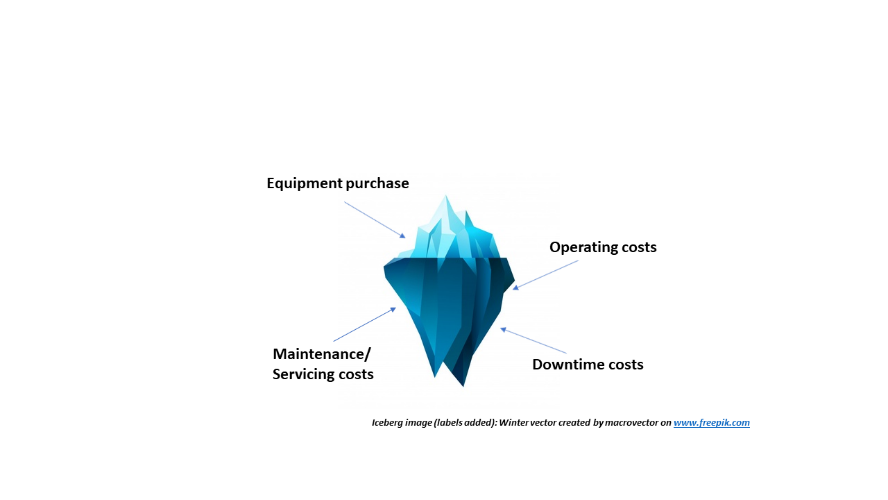

It appears not all equipment is created equal … you need to take into account not purely the capital cost of equipment, but all the additional costs too. Like an iceberg, there is plenty below the waterline:

When it comes to ink jet printers, some suppliers focus on certain operating costs only, rather than the whole picture. Some customers also focus on the most frequently seen costs, even though these are relatively small in terms of total cost of ownership.

Maintenance/servicing costs:

- Servicing requirements (reducing here through self-service module and extended service intervals saves money, of course, but also time for the production engineers as they do not need to manage line stoppages and restarts)

- Cost of service agreements

- Travel to site for service engineers to carry out maintenance (cost normally included, but also environmental issue of sustainability and carbon emissions – good to reduce)

- Cost and time taken to clean if fluid spilled in production environment, and resulting production line disturbance

Downtime costs include:

- Lost production – with possible lost orders from inability to meet agreed demand

- Possible fines from retailers if late on delivery

- Direct labour costs, along with staff stress, high churn rates and additional staff costs

- Time taken to get back to optimum output following downtime (production managers want longer intervals between servicing)

- Unplanned stoppages from breakdowns

- Even planned downtime still affects the bottom line

- How downtime is affecting your bottom line

Operating costs include:

- Consumables – not just the cost but also the ease of replacing them to keep downtime to a minimum

- Energy usage

- Cost of replacement parts

As operating costs are more easily measurable, some focus only on these when comparing different solutions. In CIJ printing, there is more focus on solvent usage than other costs, even though the actual cost difference between different products is very small compared to maintenance and downtime costs.

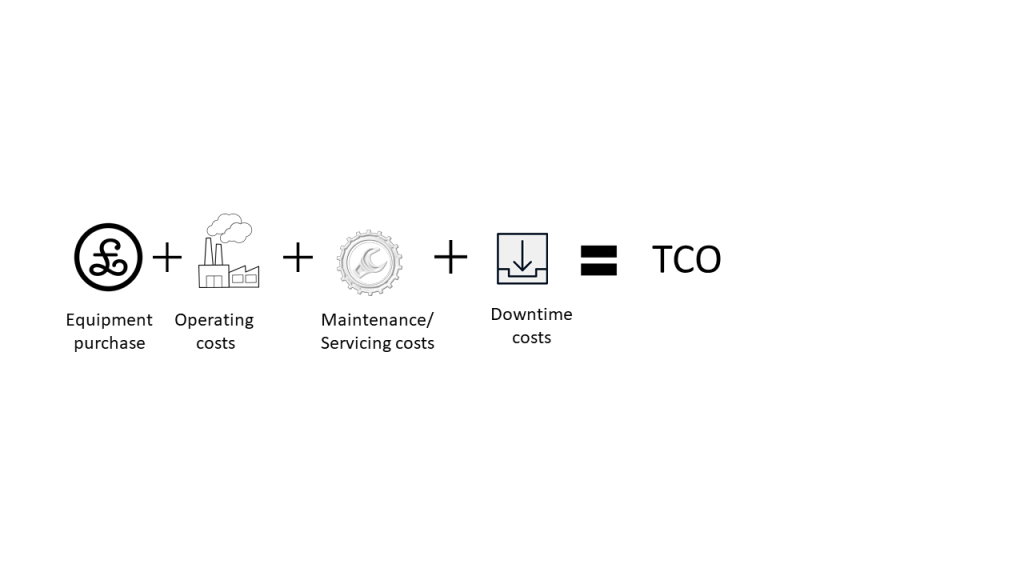

So, keep this formula to hand when looking at the TCO:

When it comes to replacing your old equipment, here are some pointers which will keep your Total

Cost of Ownership on the right side of the tracks:

- Select simple equipment management with self-servicing which can be easily undertaken by the user, following on-screen prompts

- Go for the longest time between servicing (18 months +) to ensure long, continual running with minimum interruption

- Look for the ability to book servicing around your own work schedule, avoiding unnecessary downtime

- Aim for quick, simple and clean consumable refills which can be cleanly replaced, with no exposure to fluids

- Take into account the amount of consumables that are disposed of during maintenance, or when the printer is left over holiday periods or extended shutdowns

So as outlined above, TCO is a valuable tool to understand the wider impact of an equipment purchase – which if carefully applied can reduce costs and downtime, and have beneficial effects far into the future.