How traceability codes stay put on automotive products that are exposed to wear and tear

Components in automotive manufacture are, in many cases, meant to wear. Parts like brake pads or discs for example will wear out eventually. When manufacturers also need to apply traceability codes, it is important that they last as long as the component.

How can coding and marking deliver durable codes?

Inks are a key component in inkjet coding and marking of components, and there is a large range available for different applications.

High contrast pigmented inks deliver dense print and in a range of colours, including white, yellow, and blue, thereby ensuring clearer codes on both light and dark materials. The nature of pigmented inks also provides increased resistance to wear and removal by light, abrasion and chemicals – all factors which automotive components may undergo during production, storage or end-use.

Similarly, a UV-cure ink developed specifically for the automotive and aerospace industry is ideal where aggressive solvents are commonly used in the post-print process – the printed code is passed through a UV lamp system to cure the ink to form a solid, or permanent, ink film.

Alternatively, removable codes may be needed for internal traceability, so alkali-removable inks are available for this very purpose.

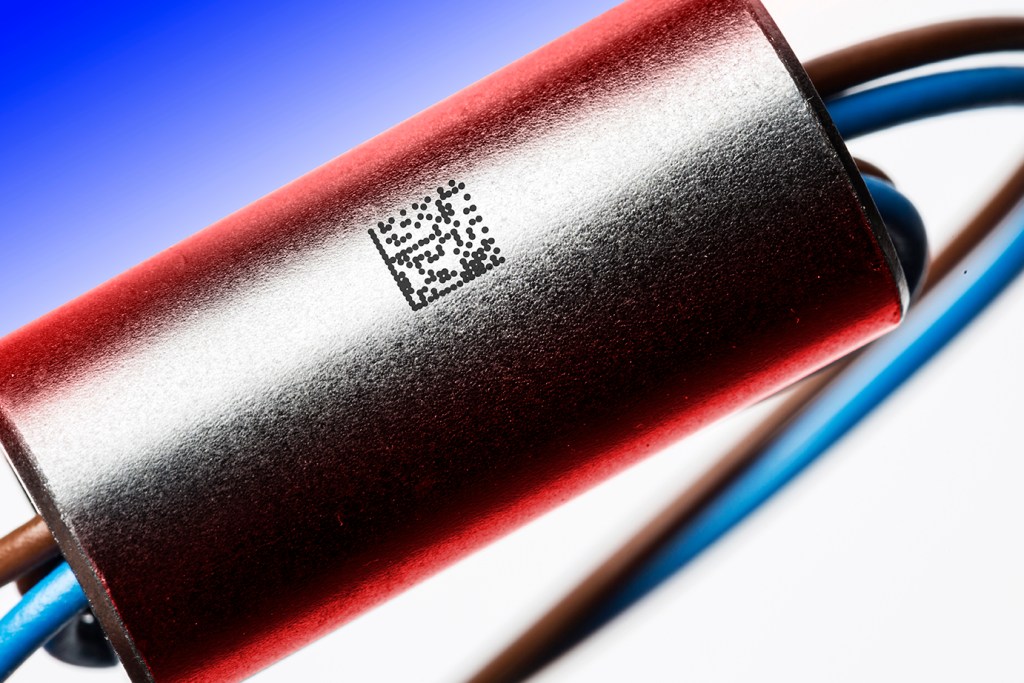

Laser coding is increasingly being used for marking automotive components because it delivers guaranteed permanence of codes, which can be high quality and also extremely small – ideal for small components.

Laser works by permanently changing the nature of the substrate to leave a mark. On plastic, a thermal or chemical change takes place to either change the colour of the plastic or to leave an etch. On glass an embossed print is created.

Reliable coding and marking for a growing industry

The auto parts industry is going from strength to strength in the UK; with turnover increasing from £9 billion in 2011 to £12 billion plus in 2017. And in anticipation of Brexit, more UK manufacturers are turning to British-made components than before.

So how can coding and marking solutions help automotive component manufacturers to keep up with this expanding industry?

Reliable coders can operate continuously in conditions that are often challenging, meaning that customer deadlines are met. Reduction of errors is also crucial: easy to use machines that can even be controlled by one central manager mean that there will be fewer delays and less downtime. And finally, robust codes as mentioned above give manufacturers peace of mind that their messages will stay put as long as necessary.

So if automotive component manufacturers have coding and marking machines that deliver consistent and robust codes, they are well placed to benefit from the growth of an industry which is a very healthy sector of UK business. Find out how traceability codes delivered by Linx printers withstand the demands of your production line and beyond. Request a sample code on your product today.