Coding and Marking on Extrusion

Coding and marking solutions for extrusions need to deliver flexibility to meet the variety of materials manufacturers might produce. The surfaces of extruded materials such as metal, ceramic, and plastic and could be printing on various surface shape which can be challenging to achieve optimal ink adhesion and good quality code readability. Harsh environments where dust, heat and humidity are present need robust printers to withstand those conditions.

We have a great understanding counterfeiting is present in the extrusion industry, however, we have many printer types to combat that issue. We have a wide range of inks and coloured inks for all material types and crisp readability. Whether you are looking for simple product name or logo, part number, connection line, or international standards marking, Linx systems offer versatile coding to include the printing of logos, text, and large codes for extrusions.

What is Extrusion?

Extrusion is a process of work metals being forced or compressed through a die hole to achieve a certain required cross-sectional shape.

Marking and coding on extruded products may present challenges, whether that is marking serial numbers, safety warnings or logos. Choosing the right marking and coding printer is crucial for a manufacturer to work efficiently and meet design standards.

How do I know which machine will be best?

Just look at the IP Code which tells us the degree of protection provided by the mechanical casing and overall design to protect against intrusion, dust and water and accidental contact.

Does Linx Ink work on extrusion?

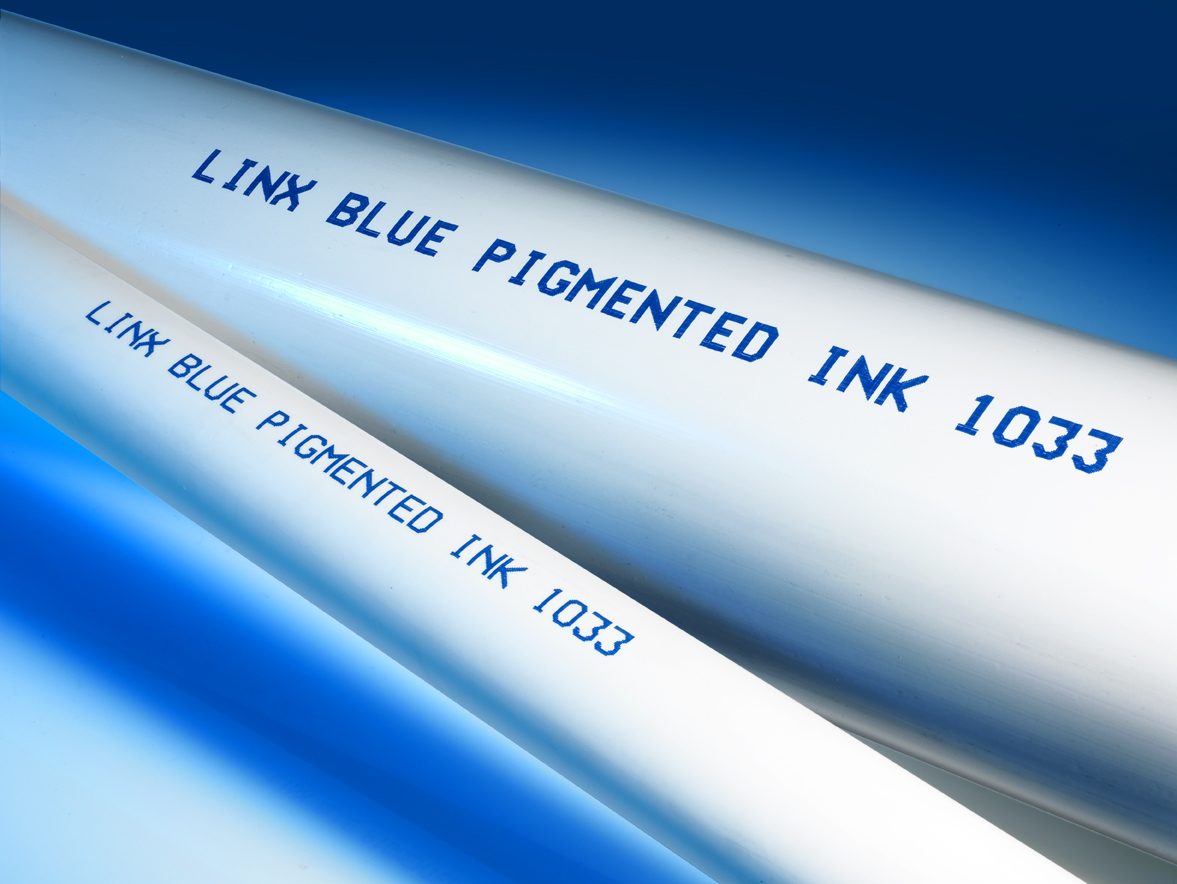

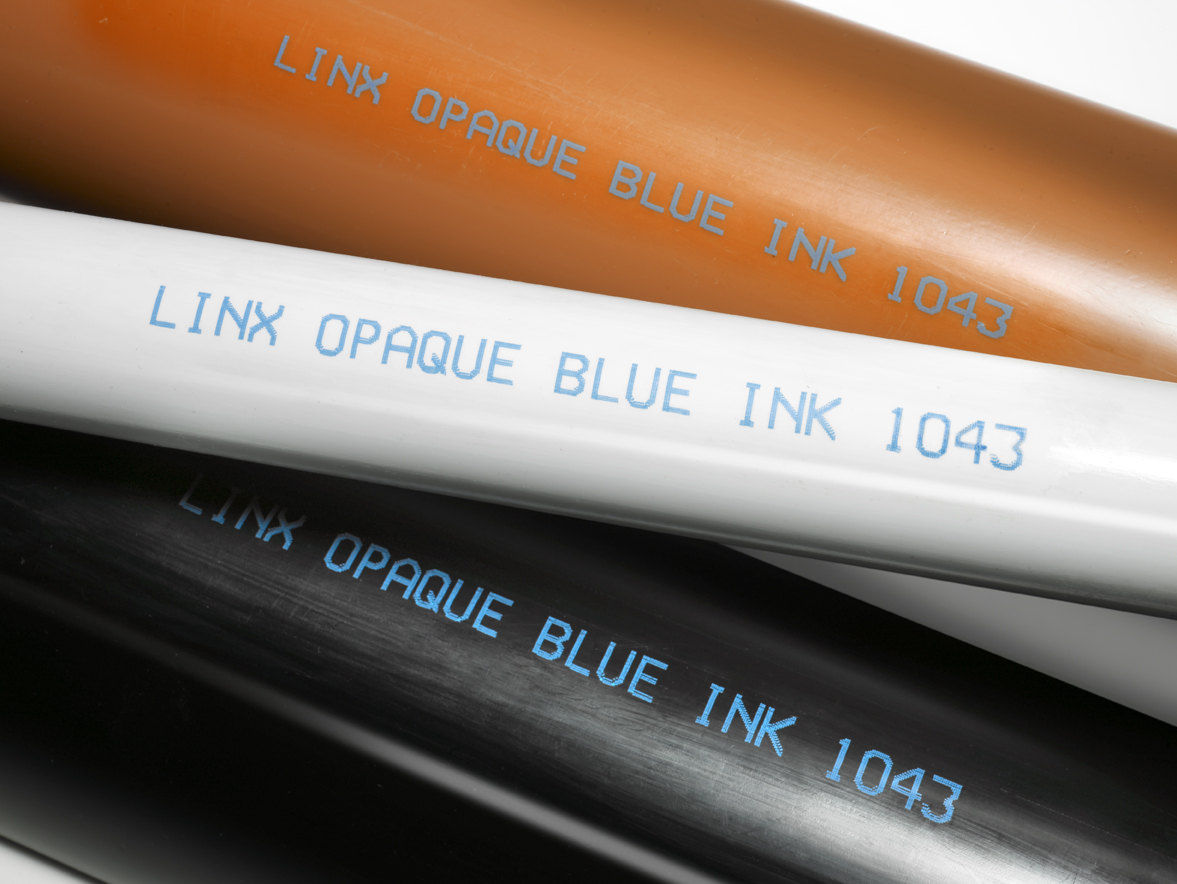

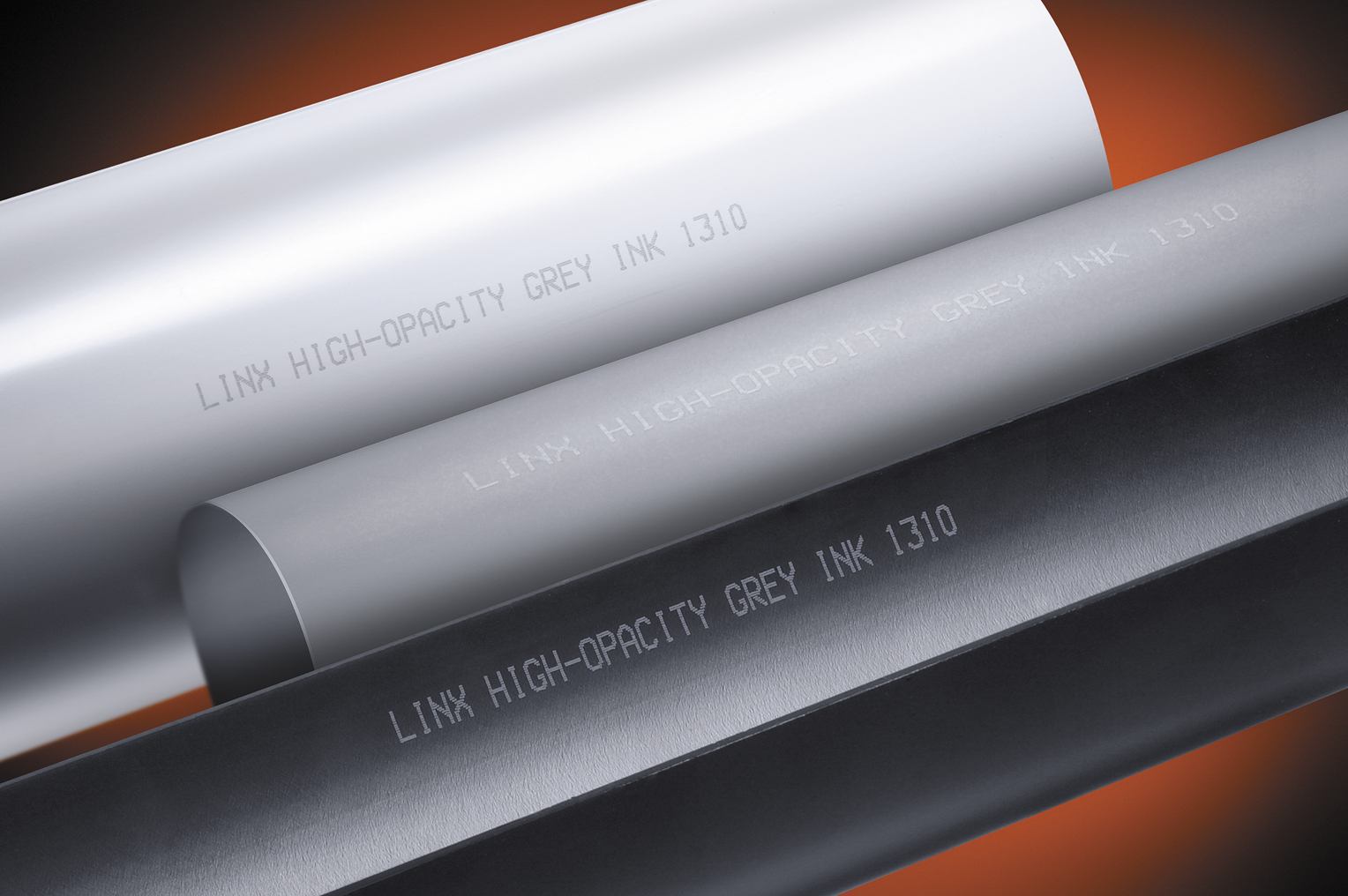

Compliance plays a vital part in the extrusion process and differs with industries. Linx offer a wide variety of inks, and we can help advise you what ink is suitable and complaint for your industry and needs. We offer MEK-free, highly pigmented, odour free, and fast drying options also. We also have grease and oil penetrating inks eliminating the needs for pre or post treatment, cutting cost and time.

What does Linx offer?

Linx digital coders provide quick and simple code changes – less downtime compared to contact printing systems, while clear coding meets industry and international code standards.

We can help to lower costs through quick and accurate code change overs, reducing scrappage, and ease-of-use ensuring fewer manual errors and therefore downtime.

Through your journey with us, you will have our support. We pride ourselves in a 97% first time fix rate, on the day or next day engineer call out, and next day fluid delivery as we are a UK manufacture making orders quick and convenient.

Contact Us

Why not get in touch with one of our sales reps to talk about how Linx can support your coding and marking needs?

Printer Types for Extrusion Marking

Continuous Inkjet (CIJ) printers

Linx continuous ink jet has been designed to withstand the harsh production environments extrusion has in store. IP rated 65 built in all stainless steel, you are ensured it can survive water, heat, and dust. Linx CIJ printers reduce ongoing costs by efficiently using inks and solvents and are designed to be durable and reliable, meeting the highest standards of coding quality.

- Capable to code from 2mm up to 22mm high

- Durable, high quality multi-line coding

- Wide range of inks to keep your codes in place on nearly any substrate

- Optional IP protection for harsh environments

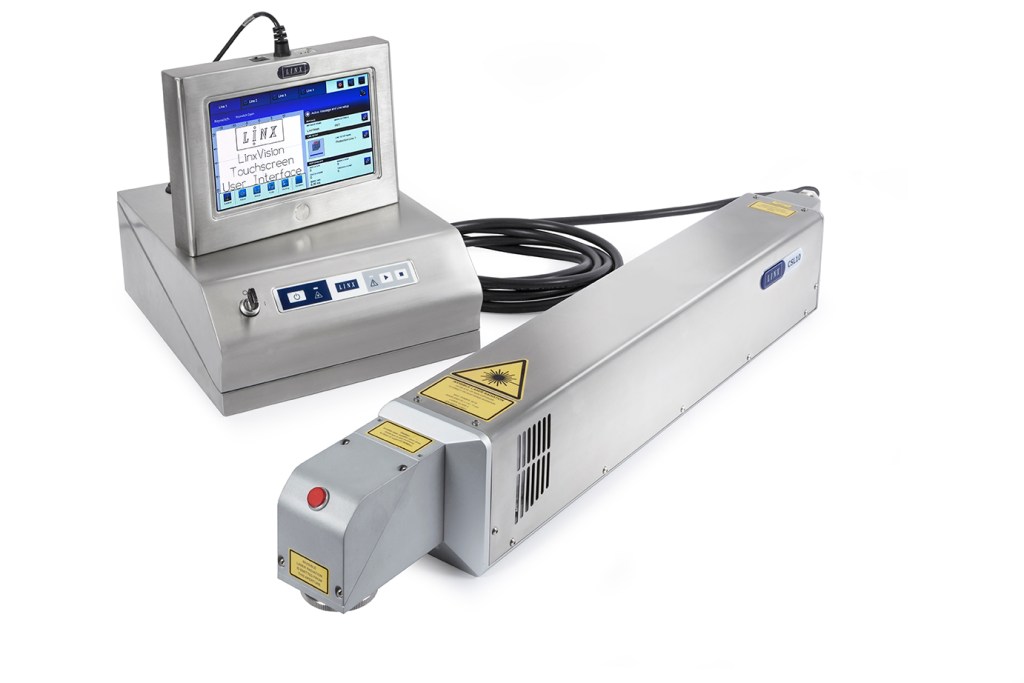

Laser coders

Laser printers are ideal for permanent coding and provide a low operating cost product marking solution. Linx laser coding machines are designed for use in challenging, high-speed production environments while ensuring industry leading text and code quality. Our Lasers can code on PVC with low surface damage with clear visible colour change on light colour material.

- Permanent marking capability

- Low operating costs – no need for consumables

- High quality coding even on the fast line speeds

- Capable of keeping pace on a fast line

Resources

Choosing The Right Extrusions Coding & Marking Solution White Paper

Linx Contrasting Inks Datasheet

Special Adherence Inks Datasheet