The importance of barcode quality in supply chain operations: An examination of how barcode quality affects supply chain efficiency and accuracy.

Barcodes are an essential part of any supply chain operation. Not only do they provide fast and accurate tracking throughout the supply chain, but they also help to ensure that goods arrive safely and on time. However, barcodes can easily be damaged or become illegible if they are printed incorrectly, causing significant (and often costly) delays in the supply chain process.

Let’s cover the basics first though.

What is a barcode?

We’re all used to seeing barcodes but in terms of their actual use case, they are usually a set of lines of various thickness in vertical format with spaces, accompanied by a set of numbers. This is machine readable and provides access to information such as the product name, type and size, though there are more applications.

There are also two primary type of barcode: 1D and 2D. 1D barcodes are what we usually associate with the term barcodes, i.e those we see in a supermarket, the vertical black lines with spaces. 2D barcodes are in a square format (QR codes) and encode additional information over and above that contained within 1D barcodes.

How are barcodes used?

Barcodes offer much more functionality than just registering if a customer has bought an item in a shop. They’re used to track products throughout the supply chain and contribute essential information to management systems that ultimately keep the supply chain operating smoothly. This can include inventory management, stock accountability, efficient warehousing operations, traceability, serialisation and more.

Due to their primary purpose as machine readable, encoded data, any issues with the printing of barcodes can have a negative impact on their usage within the supply chain. Clearly then, any production line will want to ensure that their barcodes are applied to the substrate correctly and accurately so that they can fulfil their purpose of providing key information to stakeholders along the supply chain and to the end user.

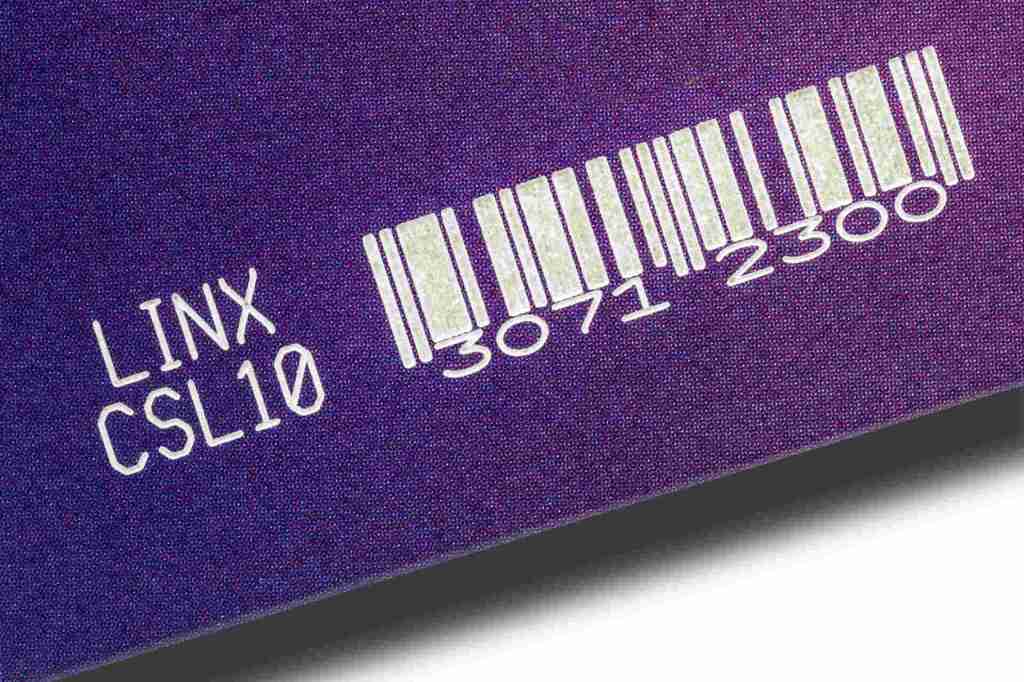

Both continuous inkjet printers and laser printers both create highly durable and legible barcodes. As above, this is critical as products are handled and pass through various stages in the supply chain where barcodes can potentially be compromised. On top of the durability and quality of barcodes, businesses also need to take into account the ease of use of these types of printers, in that both CIJ and Laser printers allow easy changing of information contained within the barcodes without having a detriment to overall production line speeds.

Below, we’ve looked at some of the applications of barcodes and their usage throughout the supply chain:

Inventory Management

Barcode labels are commonly used to identify and track inventory items throughout the supply chain. However, if barcode labels are of poor quality, it can result in scanning errors and misreadings, leading to inaccurate inventory data. This can result in delays, stockouts, overstocks, and ultimately affect customer satisfaction. High-quality barcodes with well-defined lines, clear characters, and proper placement on products or packaging can ensure more accurate inventory management and improved supply chain performance.

Automation for Barcode Scanning

Over the years, supply chains have continually invested in automation. As a direct result, these automated barcode scanning systems rely on accurate barcodes to quickly capture data and execute an action for that particular product. This automation is designed to decrease human error and increase cost effectiveness, an objective that relies on data being displayed clearly through barcodes.

Stock Accountability

Stock accountability is crucial for businesses to maintain visibility and control over inventory levels. This information enables them to streamline their supply chain based on demand, avoiding issues such as excessive stock or on other hand, lack of stock. Due to the physical space taken up by products and the costs involved with storage, businesses are always trying to reduce the amount of time they hold onto inventory without risking running out of product when there is demand. Issues with barcodes, combined with the automation of these processes can increase costs through the need for human verification and incomplete data sets.

Cost Effectiveness

Supply chain profitability relies on scale and efficiency, hence the aforementioned investment in automation. Any delays result in downtime and therefore have costs attached to them, which is why cost effectiveness is so pertinent within the supply chain. Barcodes are an essential component of this scale and efficiency, without which the automation associated with gathering and processing product level data would not be possible. That’s why the quality of barcodes, whilst initially appearing somewhat trivial, is such a critical aspect of supply chain operations. In addition, barcode scanners are incredibly cost effective and the reduction in manual errors that these alleviate mean that investment in this technology makes a lot of sense.

Cost effectiveness doesn’t necessarily need to solely apply to automated processes either. The information contained within barcodes and the processing of this information can provide businesses with insights into workforce productivity, enabling them to make data driven decisions based on real world actions.

Product Traceability and Serialisation

Product traceability and serialisation are essential in multiple industries, including pharmaceuticals, food and beverage, and electronics. Barcodes are commonly used to enable product traceability and serialisation, allowing products to be tracked and traced from the point of manufacture to the point of sale. These barcodes enable businesses to track or recall products and often provide key information required by regulatory compliance.

Conclusion

In conclusion, whilst we are all used to seeing barcodes being scanned at the point of sale, it may not at first be apparent as to how important they are in providing information to businesses throughout the supply chain. They provide encoded data that is essential to operations, whether that be retailers tracing electronics sales or warehouses keeping track of stock inventory. In fact, barcodes can provide a lot more data than we have been able to include in this article!

Barcodes can be printed on various substrates, whether that be primary or secondary packaging or even on to the product itself. At Linx we can assess your requirements and advise on the best printing solution for your needs, get in touch with us today.