Coding on Cans

Our can coders are ideal for production line coding of expiration dates and batch numbers, using non-contact printing designed to code onto metal in almost any orientation.

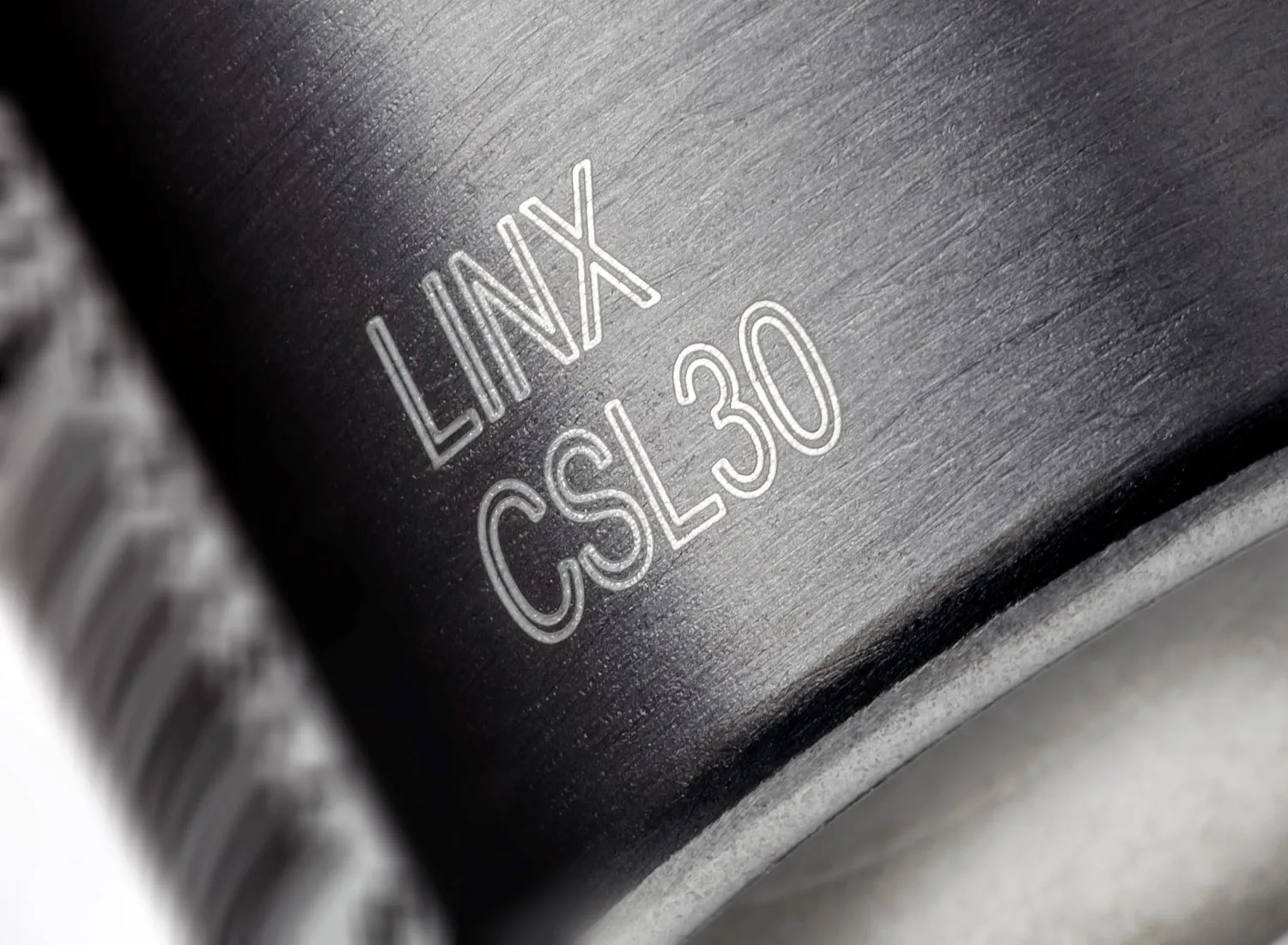

Linx are specialists in designing and manufacturing coding and marking equipment. We understand that printing onto aluminium or steel cans presents a number of unique challenges, from difficult to adhere to surfaces and wet or harsh environments, to limited marking areas. Our can coders and printheads have been designed to provide flexibility to meet all your production line printing needs.

Our intelligent printers can save time with pre-programmed codes and managed at a distance with options for remote control and monitoring via a secure online system. Linx coders can also print barcodes, datamatrix and QR codes onto tins and cans avoiding the need for labels, unnecessary waste and reducing the impact on the environment.

Linx batch and date coders are used in a wide range of industries from manufacturing beverage and food consumer packaged goods to cosmetics and chemical containers. Our expertise in product and packaging marking & identification can help you to reduce costs and improve productivity.

Production Line Can Coders

Canning lines are designed to increase production volume and reduce labour costs. At Linx we understand that reliable and consistent product marking is critical as rework adds significant cost or delays to product manufacture.

Our can coders are designed to integrate with production line systems. They are suitable for a range of line speeds and feature automated date & batch number functions to reduce manual interventions and also avoid production line downtime.

Linx also has coders suitable for specialist coding such as printing using UV and food grade inks. Our laser coders are ideal for high volume or permanent marking with no need for consumables.

Coding on Food Tins

Linx pigmented inks enable long-lasting printing of expiry dates and batch numbers onto a range metal cans, tins and bottle & jar lids providing clarity for years even if stored in daylight.

Our laser coders can also code onto coated metals or external paper and card packaging, providing rapid, permanent marking with no need for consumables or ribbon/ink changeovers.

Aluminum Drink Can Printing

Depending on your needs, Linx have high adhesion, retort and even washable inks for use on metal surfaces in a range of harsh environments and also inks to enable straightforward recycling after use.

Linx non-contact marking can also code directly onto hot or cold materials, so Linx have a product marking solution for all types of substrate and coding requirement.

Coding onto Personal Care Products

Many industries require coding of date/time and batch or lot numbers onto caps or the base of cans to enable faster production line operation or simply to remove the need for manual interactions.

Linx small character inkjet coders are designed for printing onto small circumference metal lids and caps with print that is legible and consistent.

Contact Us

Why not get in touch with one of our sales reps to talk about how Linx can support your coding and marking needs?

Can Coding Printers

Inkjet Can Coders

Ingress protection & specialist inks make our continuous inkjets ideal for coding on cans

Inks and Fluids

Special adherence and retort inks for coding onto metal product and packaging materials

Laser Coders

For high volume lines, code onto can packaging with no consumables and low running costs

Key benefits

- Robust traceability

- Up to IP65 rated printers

- Reliable operation in hot, dusty, wet, or non-temperature controlled environments

- Easy to use and accurate coding

- Range of solutions for durable coding onto most metals

Metal & Can Marking Applications

Can Date Coding

Find out how Linx coders are designed to make date marking simple and efficient

Lot & Batch Coding

Find out how Linx printers deliver clear and durable batch coding and traceability

Remote Coder Control

Remotely control and manage your production line coding over the internet

Resources

Top Ten Tips for Choosing the Right Coder

Beavertown Brewery

Coding and Marking Solutions for Beverages

Coding Solutions for Personal Care Packaging

Special Adherence Inks Datasheet

Ringnes AS

Fourpure Brewing

Coding & Marking Solutions for the Chemical Manufacturing Industry White Paper