Flexible Packaging Coding and Marking

What is Flexible Packaging

Flexible packaging is usually a form of lightweight material that allows manufacturers to package a variety of products. They are cost-effective by not adding extra costs to transport whilst still looking presentable on the retail shelf. Flexible packaging dimensions are not unique to the specific product, which allows manufacturers to alter the size of their products without having to redesign packaging. This is a very practical solution, especially for the snacks or confectionery industries.

Flow-wrapping is a very popular method of packaging products. With this technology, the product moves along a flow wrapping machine that wraps it in protective plastic films or foils consisting of clear or printed polypropylene films and seals it at both ends.

Packing products in packs using films is very popular in the food industry, especially in meat and cheese processing. It requires a sort of base for the product to be placed on that is then covered with a film that gets sealed onto the edges, packed in a protective atmosphere and often filled with a mix of gases for longevity. Films can also be used as vacuum packs, being wrapped around the product and adapting to its shape, saving packaging costs and space during transport.

Film and Flow Wrap Printing

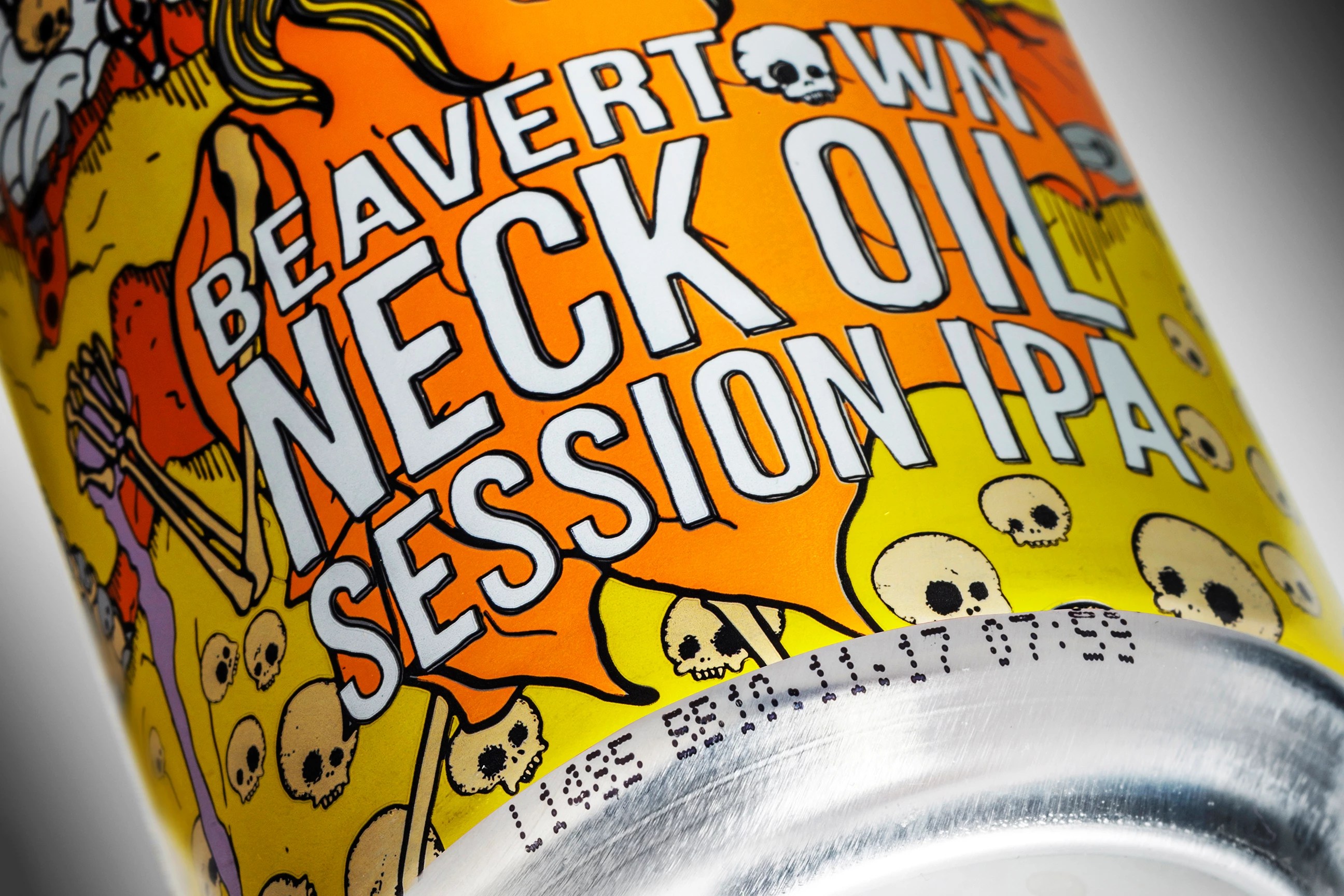

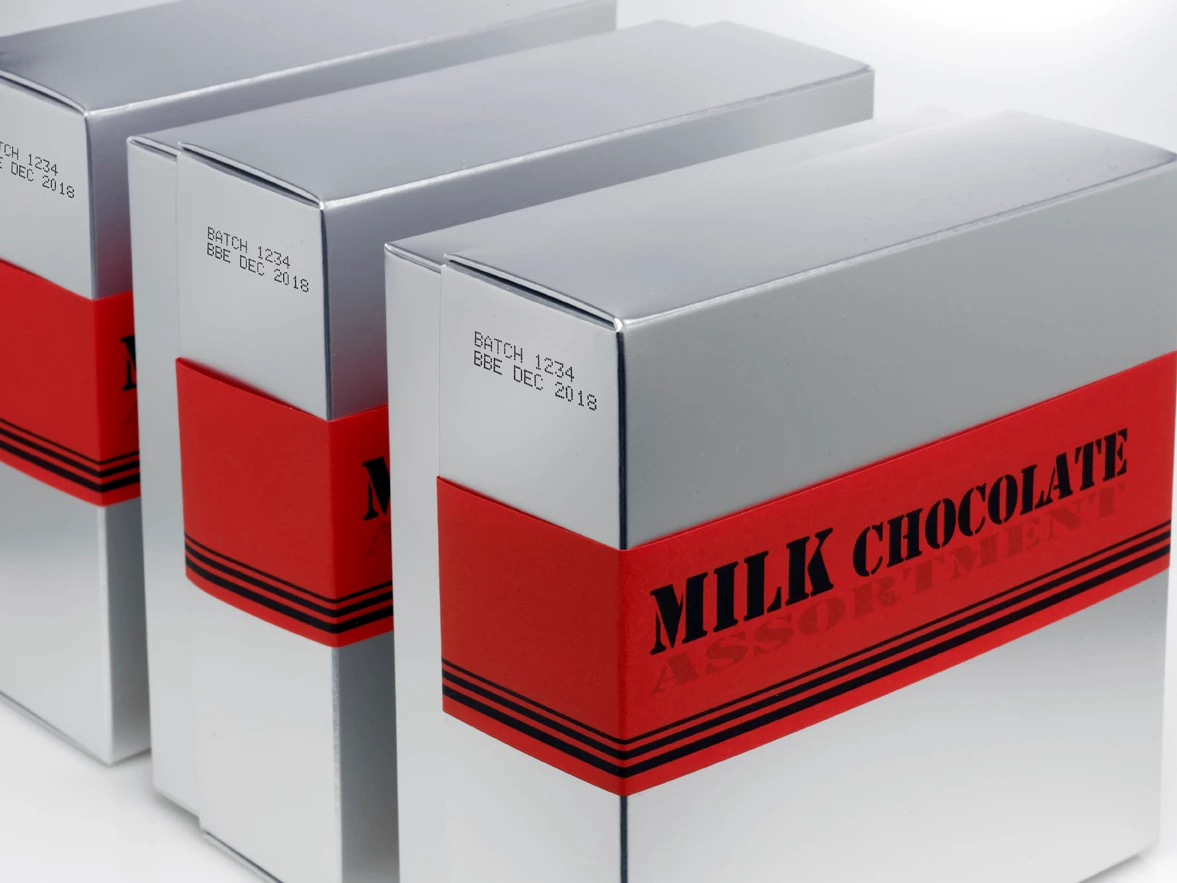

Regardless of the technology used, all flexible packaging has to meet standard requirements for coding and marking. They must have traceability and product information printed, such as best-before dates, batch codes or barcodes.

Printing on flexible materials requires technology that can ensure codes adhere to glossy and lightweight materials. Also, printing directly onto the low-density polyethylene (LDPE) and flexible metallized films used for flow wrap is not always easy.

When choosing technology for coding and marking on film and flow wrap you need to consider the speed of your production line, substrate and manufacturing conditions, i.e. wet, cold, dusty environment. The best way to check what will work and how will your code look like, is to arrange for samples to be printed. At Linx we offer a free sample marking service using continuous inkjet, laser and thermal inkjet technologies so you can see for yourself how clear and visible your code will be.

Our printers can be found applying code on films and flow wraps in many industries:

- Food

- Dairy

- Confectionary

- Pet Food and many more

Printer Types for Film and Flow Wrap Printing

Linx film and flow wrap marking printers are ideal for printing on flexible packaging or glossy films. Our range of thermal inkjet printers, robust continuous inkjet printers, and high-speed laser coders ensure that your film products have a clear code.

Our range of industrial printers offers consistent and efficient solutions for printing onto substrates such as shrink wrap, flow wrap, plastic bags, flexible packaging, PVC or PPE films.

Linx film marking printers reduce the risk of coding errors while increasing the efficiency of your production. Linx film printing machines are available for a variety of production line speeds, regardless of code complexity, and provide essential automation to traceability and manufacturing coding.

Continuous Inkjet (CIJ) Printers

Linx CIJ printers reduce ongoing costs by efficiently using inks and solvents and are designed to be durable and reliable, meeting the highest standards of coding quality.

With ingress protection and self-service modules make our continuous inkjets ideal for film printing. And if your product requires wider text printed, multiple machines installation on one line or traversing is possible with Linx CIJ printers.

- Durable, high-quality multi-line coding

- Wide range of inks to keep your codes in place even on glossy wraps and films

- Traversing or multiple machine installation possible

- Can withstand harsh production environments with optional IP protection

- Range of inks for specialist marking, e.g. food grade, invisible/UV coding

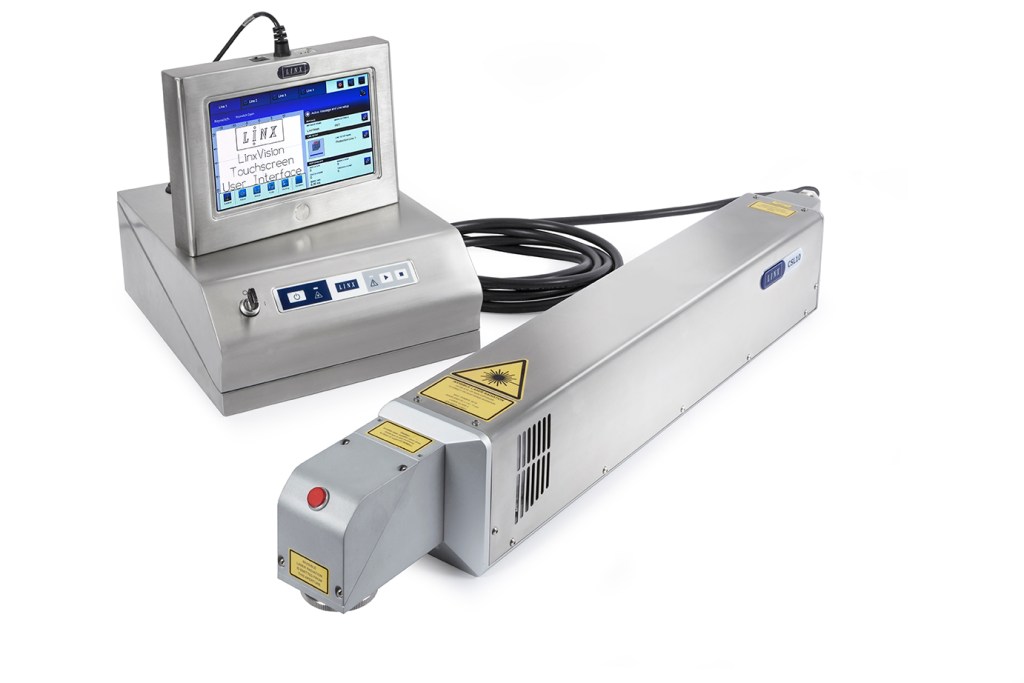

Laser Printers

Laser printers are ideal for permanent coding and provide a low operating cost product marking solution. Linx laser coding machines are designed for use in challenging, high-speed production environments while ensuring industry-leading text and code quality.

With a wide-field laser lens we can print wide web films as the line moves so traversing is not needed. Laser technology is cost-effective, as you can replace multiple CIJs machines with one laser solution.

Depending on your flow wrap and film type used, CO2, Fibre or UV laser could be suitable for marking.

Lasers can print in any orientation on moving products through the production process.

- Permanent marking capability

- Low operating costs – no need for ink consumables

- Reduce the number of printing equipment needed

- High-quality coding even on fast line speeds and in any orientation

- Ideal for flexible packaging marking

Request a Print Sample

See what your code will look like on plastic film.

To find out more information and to request your samples with no obligation, click the button below.

Working with Linx

Linx Printing Technologies have been in the industrial coding and marking industry for 35 years. We have built a team of high specialists to support all our customers through their buying process and aftercare. We have a set of highly qualified and experienced sales managers to assist from the very beginning, offering sample marking, free site visits and advice across all industries.

Worried you won’t have support after the sale? We have a UK service maintenance and support team to maintain the quality of the machines to run efficiently and effectively on your production line. To offer ultimate support we have a team of highly qualified technical support team available should you have an issue with any of our machines, we are on hand to help you get coding quickly again.

Related Industries

Food Industry

Printers for paper labels, cardboard and plastic food packaging, bottles, and even directly onto food products themselves such as eggs or cheese.

Confectionery

Meeting the demand for different types of plastic packs, in addition to the traditional paper or card outer wrappers.