Date Coding

Date coding is an essential part of most production processes. In food and beverage industries best before dates are integral to consumer safety and complying with regulations. In industrial manufacturing, expiry-date printers help provide full traceability and are crucial in the event of a recall or quality compliance issue.

What is date coding?

The answer is simple, it is the marking of each product after production with a date coded on.

Is date coding a legal requirement?

For England and Wales, pre-packed foods must mark and display information about the freshness of the product with either a use-by date or minimum durability date, that being either best before or best before the end. Other markings such as lot marking and date of freezing are printed on the packaging also.

Request a Print Sample

See how your date code will look like.

To find out more information and to request your samples with no obligation, click the button below.

Best Before & Expiry Date Printers

Linx industrial date coding machines have pre-programmed and customizable date and time formats to match every customer need.

Using real time clock functions our date coders can automatically calculate and print best before, manufacture or expiry dates. It can add a fine level of detail to your expiry date coding.

If you need expiry dates that are easily readable for your consumers or “closed dating” for meeting regulations on product traceability Linx can meet your specific printing or marking needs.

Expiry date printer

How date coders make life so easy

The food industry isn’t the only industry that uses date coders. Date coding is used in the pharma industry, cosmetic industry, and electronic and beverage industry. Each industry has a different working environment, which these coders need to be robust enough to withstand those conditions. The coder must also be versatile enough to print on a range of different substrates, from glossy boxes to plastic film.

To handle this sort of variety, Linx has a wide range of date coders and inks to make the process easier for businesses in all industries.

Printer Types for Date Code Marking

Programmed formats, automatic date forward functions, and the custom date and time editors for a full range of date coding capabilities

Linx’s best-before-date printer uses simple on-screen prompts; templates can be easily created and stored in the internal printer memory. The date coder can also be set to variable intervals for forward or back sequential numbering, with models that auto-adjust for daylight savings time.

Continuous Inkjet (CIJ) Printers

Our most customisable option with inks that can be applied to nearly any substrate; even food-safe inks for print that comes in direct contact with ingestible products!

Linx CIJ coders are renowned for their flexibility, clean operation, and reliability, ideal for long hours of operation.

- Automatic date function in the printer

- Prompted date options

- Built-in mistake proofing for date coding

Large Character Marking Printers

Linx LCM printers offer an easy-to-use, cost-effective solution for high-resolution printing. They provide an environmentally friendly alternative to pre-printed boxes or labels.

High-adhesion ink for porous surfaces such as cardboard ensures that your print remains legible even after extensive handling.

- Replace expensive labels and pre-printed packaging

- Robust nozzle protection for optimum printing performance

- Increased printing height capability – 75mm

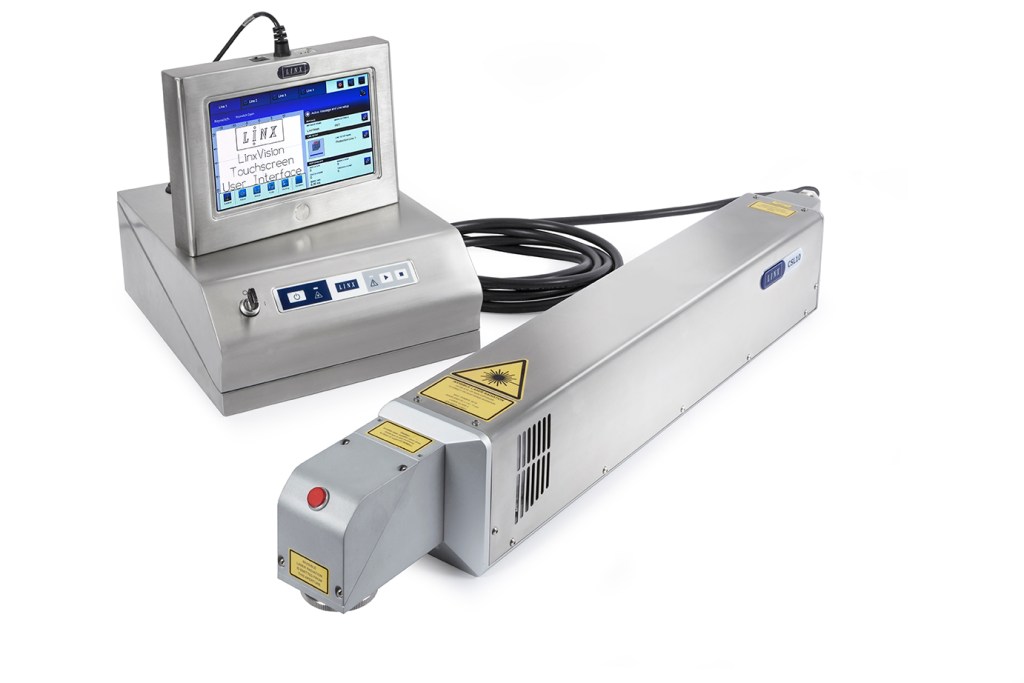

Laser Coders

One of the most reliable, versatile, and cost-efficient marking methods available. Indelible marks for even the most highly regulated industries.

With accuracy guaranteed, laser coders are a great option for high speed or permanent date marking.

- Laser tube lifespan estimated at 45k hours

- Permanent marking with fast application

- No consumables, no solvents

There are three coders Linx offer best suited for date coding. A continuous inkjet (CIJ) can be used by printing a code using inkjet. Large Character Printer can also be used by printing directly onto the product without any need for labels. Lastly, a laser can be used as a permanent solution without a need for consumables and solvent.

The price will vary depending on what model you choose and any add ons you require, for an example a trolley for easy access integrating the machine. For more information and a quote click here and one of our specialists will get be contact.

There is a long list of substrates date codes can be printed on, a few popular ones being PVC, glass, acrylic, polyester, polyethylene. For more information click here and one of our experts will get in contact.

Working with Linx

Linx Printing Technologies have been in the industrial coding and marking industry for 35 years. We have built a team of high specialists to support all our customers through their buying process and aftercare. We have a set of highly qualified and experienced sales managers to assist from the very beginning, offering sample marking, free site visits and advice across all industries.

Worried you won’t have support after the sale? We have a UK service maintenance and support team to maintain the quality of the machines to run efficiently and effectively on your production line. To offer ultimate support we have a team of highly qualified technical support team available should you have an issue with any of our machines, we are on hand to help you get coding quickly again.

Ways of Using Expiry Date Printers

Resources

Powerhaul International Case Study

Ways of Using Expiry Date Printers

Pharmaceuticals

Accurate and legible codes for high-speed production lines.

Cosmetics and Toiletries

Our solutions can help meet legislation and reduce your overall production costs across many different pack formats and material types.

Food Industry

High quality, legible expiry dates and codes to meet food grade printing and marking standards