Baked Goods

The baked goods industry presents many challenges to manufacturers, from a broad variety of packaging types to dusty production environments that test the reliability of your packing line equipment.

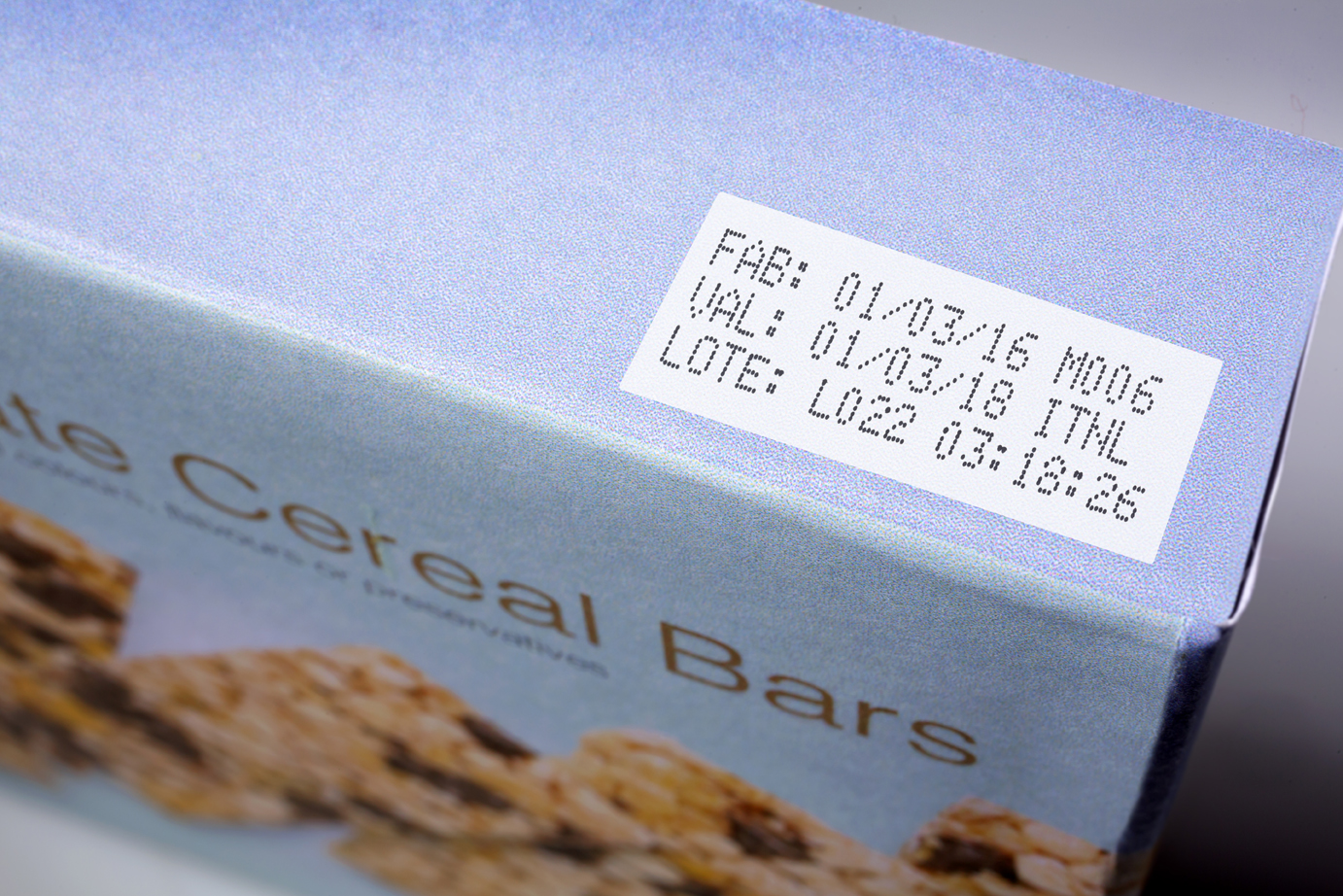

With little chance to rework or recode baked products, first-time code accuracy is important; this includes error-free code setup as well as code legibility and durability during end-use. Linx printers are easy to use without complicated menu systems, making code setup and selection quick and simple.

As the baked goods industry experiences more product diversification – such as healthier, sugar and gluten-free options – so the packaging requirements become broader, meaning your coding equipment must keep up with the changes.

Whether you’re looking to improve the productivity of your line, or need a quality coding solution for the diverse range of packaging types found in the baked goods industry Linx can provide a solution to meet your specific needs.

Continuous Ink Jet (CIJ) – perhaps the most cost-effective choice for baked goods marking and coding, CIJ maintains an important place as it can print on almost any substrate. A wide range of inks are available to use with CIJ printers including coloured inks to ensure legibility on any colour substrate, UV-readable inks for anti-counterfeiting or water-removable inks for internal traceability, adding yet another dimension to the coding process.

Request a print sample

See what your code will look like.

To find out more information and to request your samples with no obligation, click the button below.

Contact Us

Why not get in touch with one of our sales reps to talk about how Linx can support your coding and marking needs?

Resources

Mar ne Vall

Coding Systems for Lean Production White Paper

Erlenbacher Backwaren Case Study