Marking and Coding on Confectionery

Product coding in the confectionery industry needs to be flexible. With changes in consumer tastes, health motivations and fluctuating raw material costs, the confectionery industry is constantly evolving, so manufacturers need to keep pace.

Keep up with customer demand

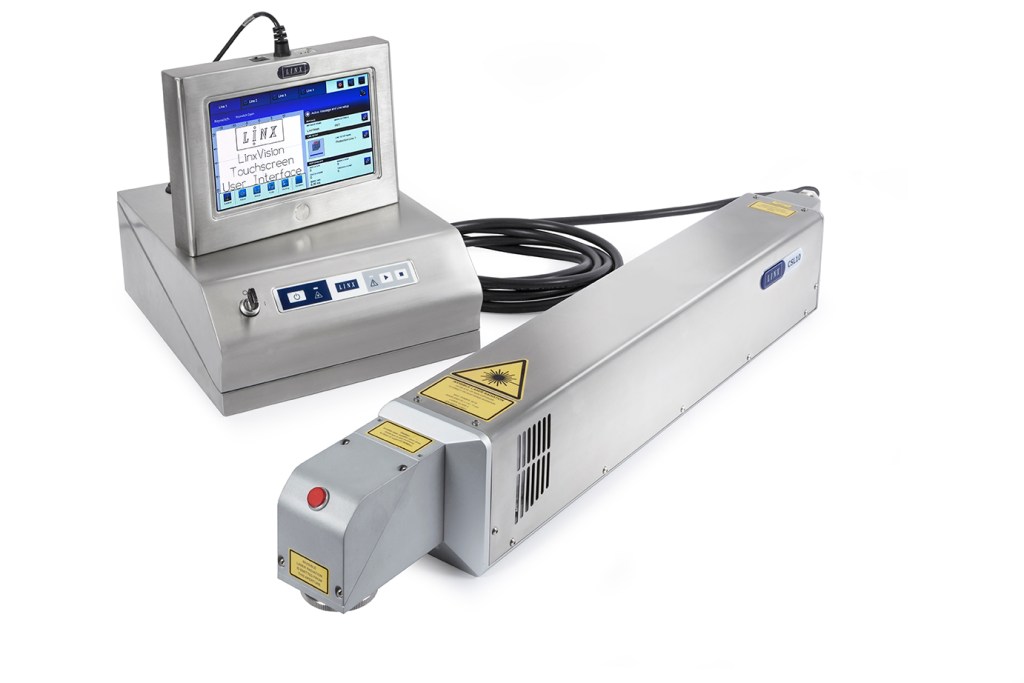

Keep up with customer demand with a high speed and permanent coding solution. Linx CSL Lasers code at line speeds up to 900m/min and can apply complex messaging including logos and competition codes. Reduce your operating costs and downtime with no consumables, minimal maintenance, and a long laser tube life. IP65 rated full systems for reliable operation in wet and dusty production environments.

Meet production targets

Ensure your batch printer operates reliably around sugar dust or water. The Linx 8940 inkjet printer has a IP65 stainless steel enclosure to support reliable printer operation in environments where sugar dust is present. Ideal for clean production environments and washdown procedures – protects against water and dust ingress for less unplanned downtime.

Save money and inventory: replace pre-printed boxes and labels with high-resolution printing of text, graphics, and logos directly onto secondary packaging. The Linx IJ355 & IJ375 prints images up to 70mm high onto porous substrates such as paper and card.

Focus on production

Save time changing messages between batch runs and move away from smudged codes or removable labels, with the Linx 10 ink jet printer. The smartphone-inspired screen ensures the right batch code messages are quickly selected, first time every time. Reduce mistakes and costly reworks. The portable Linx 10 is ideal for short batch runs, such as contract packers and manufacturers of artisan confectionery.

Meet regulations and expectations of your customers

Ensure your confectionery coding meets food standards regulations by using the right ink for the right application. Linx food grade inks for Linx inkjet printers are ideal for printing promotional messages on the inside of wrappers and meet FDA and EU regulations. Find out more about suitable applications for Linx food grade inks.

Quality confectionery deserves a quality batch code. Permanent laser coding solutions from Linx deliver a wide range of font types, so your traceability information can match your product branding. Suitable for a range of substrates from flow wrap to card and painted metal, Linx CSL laser coders deliver clean, clear coding even on high-speed lines.

Reliability

Linx coders are designed for continual, reliable operation, even on high-speed lines and in production environments which are affected by moisture and sugar dust.

Code quality

Code requirements may be simple and driven by legislation. Stringent food regulations and the importance consumers place on the quality and accuracy of labelling information means this is something no manufacturer can afford to get wrong. Linx coders deliver high-quality, high-resolution codes onto both primary and secondary packaging, so your brand is protected.

Ease of use – maximise your productivity

All Linx printers are designed with the customer in mind. Quick message setup and retrieval via intuitive colour touch screens, self-service options, and long service intervals ensure the minimum of downtime to maximise your productivity.

All Linx printers are designed with the customer in mind. Quick message setup and retrieval via intuitive colour touch screens, self-service options, and long service intervals ensure the minimum of downtime to maximise your productivity.

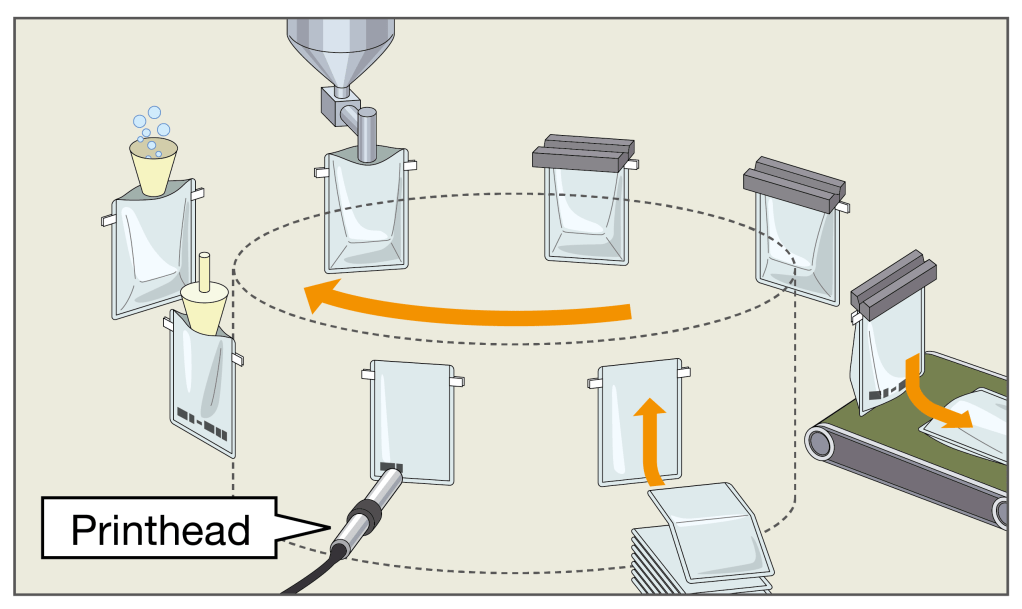

Expiration date printed on sachets

Our printers can be easily integrated onto your production line with minimal disruption. Our engineers are highly trained to set up and connect the machine without having to stop your line. Linx offer a wide variety of inks able to print on sachets and pouches statically, rotary or any other direction. If you have a unique production line and not sure how you can change to a Linx machine, our specialists can offer bespoke solutions to your problem.

Find out how we did that with ION Science – Case Study

“Thanks to the Linx printer’s speed and great versatility, which

minimises downtime, we can meet our tight deadlines

efficiently,” says Carol Oldbury, Director at Hames Chocolates

Printer Types for Confectionery Printing

Continuous Inkjet

We understand cleanliness is a top priority for food industries. Our Continuous Ink Jet have been designed in all stainless steel at an IP65 rating meaning a high level of protection for any accidental contact and ingress of dust and water from any direction.

- Provide non-contact, high speed coding capabilities and easy to use interfaces for quick, error-free code changes

- No spill on the line with mess free refill system

- Auto cleaning printhead minimising mess and downtime

- Wide variety of inks including MEK free suitable for food packaging

Laser Printer

Fast, non-contact solution offers permanent, high quality batch coding of confectionery packaging on a wide range of materials including coated foils, paper, and plastic film packaging.

- No consumables, no solvent

- Able to print static at high speeds

- Range of performance powers – 20, 50 and 100 watts

- Able to mark on flow wrap without piercing holes

Large Character Marking Printer

A cost-effective alternative to labels and pre-printed boxes, ideal for secondary packaging.

- Print text and graphics to a high resolution

- Protect your brand with quality box printing

- Barcode, Databar, Data Matrix and QR Code printing

Contact Us

Why not get in touch with one of our sales reps to talk about how Linx can support your coding and marking needs?

Related Applications & Coding Types

Barcode Printer

Printing a clear barcode is an important component of many packaging processes.

Resources

Thorntons Case Study

Special Adherence Inks Datasheet

Confectionery White Paper

Coding Systems for Lean Production White Paper

Gida Case Study

It is important to know what each laser has to offer. Many things need to be considered such as what material is going to be marked, the required speed, or whether the production will be static or a moving product on a production conveyor or belt. Then either industrial lasers from CO2 or fibre will be chosen depending on the material to be marked. CO2 laser marking are often used for softer material, example being paper, cardboard, or soft plastics. Fibre lasers are more typically used for metals and harder plastic materials. We have experts on hand to guide you through which is best – contact us here.

A: Yes, we do. If you are unsure how our machines will perform in your production environment, we can offer you samples on all sorts of material and conditions. Contact us here to get you started on the process.

Yes, we do. We have a highly skilled UK service maintenance and support team to maintain the quality of the machines to run efficiently and effectively on your production line.

Our CIJ and IJ printers can be easily moved between production lines and conveyor belts. With laser coders you have to make sure the guarding and safety equipment are also moved. A series of beam delivery options offers safe and easy manoeuvrability into tight spaces, while a simple ‘plug ‘n’ play’ configuration means you can integrate Linx lasers into your existing set-up with minimal disruption to existing workflows. Equipped with a Beam Turning Unit, Linx lasers can be adjusted to code and mark at multiple angles.